As a premium contract manufacturer with nearly six decades under its belt, Trenton Forging Company is as authentic and dynamic a partner as any customer could wish for, providing its client partners—in every market from automotive to automation—with a wide range of forged components.

The company also serves the military, agricultural and forestry, heavy equipment, and railway industries. More recently, it made a debut delivery to its first client in the medical sector. Alongside its work in all these markets, the company notes a marked increase in the demand for commercial firearm components.

As President Chelsea Lantto points out, blacksmithing is nearly as old as civilization itself. With an iron will and an even stronger commitment to continuous modernization, the company recently revealed impressive upgrades to its 100,000-square-foot production facility in Trenton, Michigan. While its five identical hammer lines traditionally formed the backbone of the company’s offering and made low-volume work possible, its leadership believes that remaining relevant trumps tradition.

As a result, and partially fueled by potential future labor shortages, robotics is now being employed to complete repetitive tasks in work environments unfortunately considered undesirable for a modern workforce. Despite the forging environment remaining as hot and loud as ever, automation has freed the company’s growing workforce to execute the complex tasks better suited to providing a more satisfying work experience.

“There is a lot of opportunity in new equipment and new technologies,” says Vice President Dane Moxlow of the art of thriving in an age of increasing volumes and higher costs.

The company’s heftiest investment rolls in at around $7 million, comprising a fully-automated forging system based on a 2,500-ton press that needs human involvement only for loading base materials and collecting the final product. To house all the new equipment of the system, the company built another facility on site, with specialized foundations to accommodate the weight and impact of the current process machinery plus two more planned systems—all in record time.

Built in less than 12 months—during the peak of the global supply chain chaos—the building allows the team to produce much heavier components consistently while adding a second shift to its production output. This is a dream that had been, up until now, prevented by local by-laws preventing nighttime noise pollution. In this way, Trenton Forging can now answer its clients’ need for repeatable, high-volume component runs, something the company has seen a significant increase in as some manufacturers return production to the United States following the supply-chain issues of recent years.

Unlike many others in manufacturing, Trenton Forging Company also has a growing staff of nearly 100, and its leadership is full of praise for the people that make up the team. “We can’t do what we do without our team members. They are the heartbeat of the company,” says Lantto. There is indeed a lot to be said for working in an industry that can be as tough and demanding as this.

“The culture around manufacturing as a career is not what it used to be. Many of our competitors are in the thick of having ongoing manpower issues. That’s not the case for us,” she says, confirming that the company is well-prepared for labor fluctuations through thorough training, ongoing development, and maintaining a positive company culture. Indeed, Trenton Forging Company’s reputation for excellence is such that a recent, urgent call from a Tier 1 customer in a bind saw the fully approved production parts roll out of its doors only four weeks later.

To ensure quality standards are maintained across all its markets, the company is compliant with the International Standards Organization’s 9001:2015 quality management certification. To this end, Trenton delivers in-depth quality checks on even the lowest-volume component runs, ensuring that longstanding customers repeatedly return for continuity on everything from simple to complex jobs.

In addition, strict data collection measures are in place, allowing detailed insight into every process. The company also has an integrated strategic energy management system to ensure power resources are used wisely.

“We lead an extremely successful company as a unit. Given the statistic that people love to throw at us about third- and fourth-generation failure rates, it happens, luckily, to light our fire,” she says of the tremendous privilege of teaming with a sibling to lead the legacy company.

Founded by George Moxlow in 1967 on land that had been a cornfield until he took up a shovel and dug the foundations of the original building himself, Trenton Forging Company is proud to still call 5523 Hoover Street in Trenton, Michigan home. Today, the historical footprint is contrasted by an ultra-modern forging outfit prepared to serve the United States and beyond with expert knowledge and technology to facilitate reverse engineering, forge tooling, forging, welding, machining, and more.

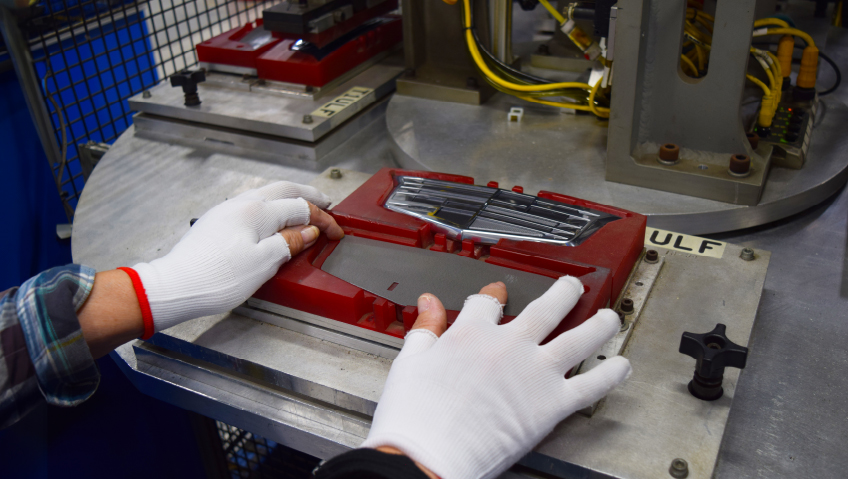

Forgers hot-work steel and other metals into components under high pressure, lending significant additional strength to such parts while keeping the grain structure intact. Thanks to Trenton’s intelligent and nimble set-up that includes an on-site tooling facility, the company is especially in demand for delivering custom work that is tough to come by these days.

By continuously expanding its capabilities and capacity, the company meets customers’ needs for low- and high-volume work at a price and value level that positively distinguishes it from other suppliers—despite heavy ongoing Asian competition. This work ranges from specialized, job shop volumes to high-volume, repeatable work. To further support its automation process, the company aims to hire another 40 staff members or so over the next five years.

“We are taking the onshoring opportunities extremely seriously—not just for Trenton Forging but for the forging industry in North America as a whole. Because it is incumbent upon all of us within the industry and supply chain to make sure that we avoid what happened in microchips with forgings,” Lantto says, pointing out that if it floats, flies, or rolls, it contains forgings.

“The world runs on forgings; they fuel the global economy. So we have to make sure that we do everything we can to keep that forging capacity, knowledge, and know-how stateside,” she continues. One factor that will continue benefitting Trenton Forging Company well into the future is its competency in planning—a characteristic its customers and staff have come to know and trust implicitly.

Leading with resilience, sustainability, and the ability to adapt rapidly, as was evident with establishing its new facility, the two young leaders are well equipped to take their family legacy to the next level with an ever-growing range of quality critical components, building on the five acres of land their grandfather dug with his own two hands.