For 30 years, engineers and managers at leading manufacturing companies have trusted Impact Fab, a full-service custom fabrication shop with two locations in Holland, Michigan, to construct the high-quality parts they need for business success.

Impact Fab’s clients know that if they bring their concepts to Impact Fab, the experts there will find a way to build them accurately and on time, because for Impact Fab, “anything less than the highest quality is not good enough.”

We spoke with Ross Haan, President, who co-owns the company with his brother Brad and their parents Dave and Betty Jo, who started the business in the family’s 400-square-foot garage with a welder, a drill press, “and a lot of hard work,” says Haan.

“After a while, we had four people working out of our garage, and that was when my parents thought they should make it an official business but decided to rent space first, to see if it would be viable,” he explains. “That was in 1994. My dad joked that he’d work hard for two years and if the business didn’t take off, he’d get a ‘real job.’ 30 years later, he still says that he’s never had to get a real job.”

30 years on

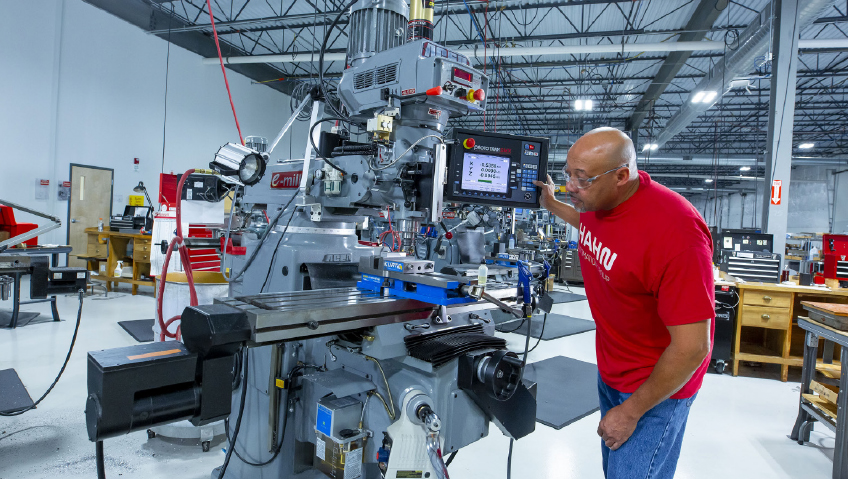

Today, Impact Fab operates out of two manufacturing facilities, one with 70,000 square feet of manufacturing space and the other with 10,000 square feet. Impact Fab offers waterjet cutting, laser cutting, metal forming, welding, CNC machining, and CAD engineering services to manufacturers, and employs 51 people.

Haan, however, prefers to call employees ‘team members,’ because they and their teamwork are what lift Impact Fab above the norm. “Our equipment doesn’t make us special, because we don’t have a single piece of equipment that’s unique. It’s our team members who make us special and unique because the skills and attitude they bring to work help our customers to excel.”

These fabricators and technicians, all expert craftspeople, have the skills to take on complex fabrication projects across diverse sectors, from initial design and prototyping to final assembly, working with an array of materials including metals, plastics, and composites.

Organic growth

Haan explains that the company has taken a non-traditional, organic approach to its growth by focusing on its customers, understanding their needs and challenges, and responding by investing in the appropriate equipment and capabilities. This has organically broadened its growth and naturally brought about a complete, one-stop job shop.

“We just wanted to be the ‘easy button’ for engineers, who don’t have to go to several shops to get their project done. They can send the entire project to us and we can do it,” Haan explains.

Operating from what he calls “an abundance mentality,” Haan is pleased to see the trend of manufacturing offshore reversing, with more manufacturers coming back or ‘reshoring.’ Once again, Michigan and West Michigan in particular is reclaiming its place as a hub of the U.S. manufacturing industry, with aerospace, environmental testing chambers, material handling, specialty automation, furniture, and automotive all part of it.

“We feel extremely grateful to be a small part of this larger community,” Haan says. “There are so many great manufacturers and so much opportunity here now that we don’t need to go out and compete and take work away from anyone else. But what we can do is keep adding value to the companies we partner with and serve, so that they can continue to grow. We’re not seeing anyone else doing that, so we stick to our core values of being curious and agile and applying those values to help our manufacturing customers succeed.”

Whatever you need

Does a manufacturer really need a 16-foot-wide by 14-foot-high by 20-foot-long chamber? Haan’s father’s motto was, “If we can’t build it, you don’t need it,” something that “customers will throw back in my face if I say, ‘we can’t do that,’” he laughs. “They reply, ‘What do you mean? It says that on your T-shirt.’”

And yes, it turns out that one manufacturer did indeed need an enormous chamber with some very specific design requirements to carry out in-house environmental tests, and turned to Impact Fab with only a rough concept.

“They said, ‘here’s what we need, can you help us get to that goal?’ That meant we were with them from the beginning, looking at material selection, panel sizes, weight requirements, and that early partnership allowed us to successfully build it for them and do it cost-effectively.”

This neatly illustrates Impact Fab’s culture of curiosity and agility—of the company asking itself, ‘How can we do this? How can we make this better?’

It’s about moving forward with innovations on a project-by-project basis, developing relationships with manufacturers, and becoming the resource they reach out to, to build the precision equipment or components they need, so they, in turn, can move forward, win bids on significant projects, and satisfy their customers with outstanding results.

Solution provider

Haan says that while Impact Fab is not a design company, it is a “solution provider” for many companies, among them Plascore Inc., a global manufacturer of honeycomb products used to strengthen structures in commercial, defense, and aerospace aircraft.

When they had a project that required six large heat-form fixtures for two jet engine nacelles (the streamlined enclosures that house the engines and components), they turned to Impact Fab, supplying only a CAD concept of the aluminum fixture they needed and its specifications.

A talented tradesperson led the team from there, recognizing that the entire project had to be thought through before the 3D machining could create the final shape, and all the specs adjusted including material type, thickness, tolerance, strength, welding type, and final inspection. Through Impact Fab’s solutions, the company not only delivered the nacelle components on time and budget, but with a 50 percent reduction in development time and thousands of dollars saved on material costs and machining.

Since then, Plascore has continued to partner with Impact Fab on similar projects. Writes Ryan DeMeester, Plascore’s Business Unit Manager, “The partnership with Impact Fab has allowed us to solve complex problems with reasonable solutions that work for both parties. They stand by their commitment to achieving their customer’s goals and staying committed to the lead times without sacrificing quality.”

Another company to benefit from Impact Fab’s solution approach is Dematic, which manufactures material handling equipment. This company’s large vehicle weldment required a large amount of extra machining after the frame was built. The technicians at Impact Fab saw a way to improve the design and the process, lowering the cost of each frame by $2,000 while still meeting all the project’s specified requirements.

A company to watch

It is success stories like these that led the Michigan Small Business Association to name Impact Fab as one of ‘50 Companies to Watch’ this past May. “We were surprised and honored,” Haan says. “We didn’t think we were even in the running.”

Underpinning these successes and recognition are those core values of culture and mindset to which Impact Fab has remained true since its inception 30 years ago, including the company’s care for the team, the environment, and the community.

“Competitive pay is a hallmark for us, along with a good benefits package which includes a six percent 401(k) match. We invest in our people’s future, paying for education and specialty job training, and we keep our facilities air-conditioned, so even in the hot summer months we work in a reasonable temperature.”

Concerning the environment, Haan tells us that since the beginning, the company has focused on reducing, reusing, and recycling, which he calls smart business, and shares that, “we’re always looking for ways to reduce our carbon footprint, having recently purchased our first electric delivery vehicle.”

He notes that the steel fabrication industry is only just realizing how important environmental considerations are and turning to what is called ‘green steel’: using renewable energy and a cleaner process than has been the norm for a century.

The Impact Fab team loves to give back and contribute to the broader community as well. The company belongs to some local organizations that do fantastic work, Haan says, including the regional economic development agency, which has been instrumental in bringing jobs to western Michigan; the West Coast Chamber; and the Lakeshore Advantage, which are all helping to build the local economy for future generations.

Looking at what is to come, Haan says, “I would describe myself and our team as rational optimists. We understand that many headwinds affect us, nationally and internationally, but I have an extremely positive outlook about what the future holds—for both manufacturing and our people—because there are just so many good people here. It makes me realize there is nothing we can’t figure out.”

Find out more at https://impactfab.com/.