When asked what makes Michigan-based, Class A automotive components manufacturer Lapeer Plating & Plastics, Inc. (LP+P) unique, Human Resources Administrator Joe DuBreuil is quick to reply.

“It’s the fact that we’re kind of a one-stop shop. We do injection molding, chrome plating, and assembly in one building. I think that’s pretty unique for manufacturers; usually, it’s just one or the other. Raw material comes into our building, and finished parts come out,” he states.

The company’s made-in-America ethos also helps it stand out. “Over the last 10 to 12 years, a lot of injection mold and chrome parts have gone offshore. They’ve gone to Asia. As a result, there are a number of chrome platers that are not around anymore. Lapeer is not only still around and making parts, we’re growing our business. I think that shows a lot about the commitment of our organization,” notes LP+P Commercial Director Mike Hitch.

Founded in 2010 after a firm called DOT Industries restructured, LP+P maintains a 135,000-square-foot manufacturing facility in Lapeer, Michigan. Space inside the company plant is divided by thirds. “A third of that square footage is for injection molding; another third is the plating line; and then the other third is assembly and paint,” Hitch explains.

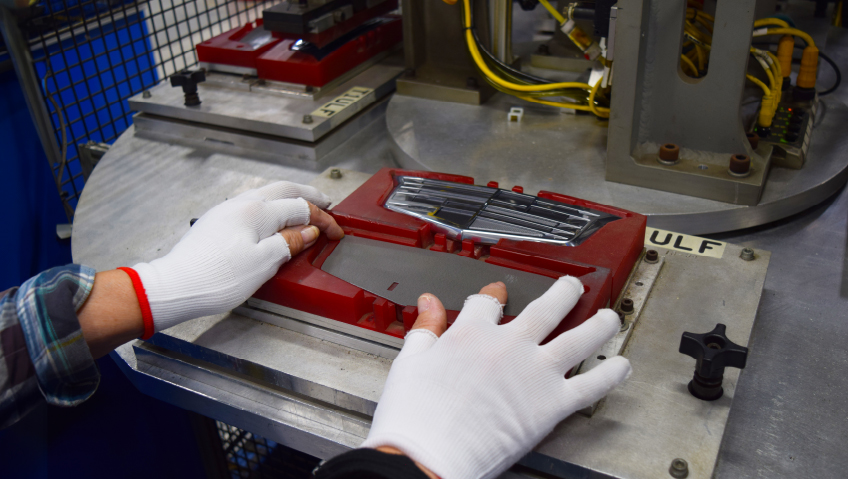

For molding purposes, the company uses more than 30 presses ranging from under 140 tons to over 1,400 tons as well as robots and injection molding machines capable of handling an array of resins. Electroplating is done via a high-end plating line that can apply matte, chrome, and other finishes. The assembly division boasts multiple work centers and performs activities such as ultrasonic welding and heat staking—using heat to join parts, one or more of which is made from plastic. The LP+P facility also features overhead cranes, a wastewater treatment system, and wide aisles to make it easier to move and handle equipment.

Additional services include computer-aided design to develop products as well as engineering, painting and post-plating, and acrylic production, a process involving specialized presses. Hot stamping, mask-painting, and vacuum metalizing can be performed post-plating.

Most work is self-performed; the company is “fairly vertically integrated, and just about everything we do is done at our production facility. We have outsourced a little bit of injection molding because some of the parts require heavier machines than we have,” says Hitch.

Products are grouped into the categories of moldings and grilles, decorative trims, and emblems and ornamentation. Examples of wares in the first category are body side moldings, which are installed in car doors to add a level of protection from damage, or ornamental vehicle grilles that boost visual appeal. Decorative trims include chrome-plated interior trims, exterior decorative trims, and headlamp and tail light trims to enhance the look of a vehicle. Emblems (also called badges) are decorative components used by auto manufacturers to brand their vehicles and are usually assembled within a grille.

Other products in this category include such items as decorative nameplates stating the vehicle’s brand and name. These are often chrome-plated and placed on the back or side of the car. Other ornamentation includes pieces such as decorative accessories for the hood, rear, and side panel, to augment the nameplate and emblem.

LP+P primarily serves the automotive sector and counts huge OEMs such as General Motors as customers. The company recently decided to expand its market reach in the transportation sector.

“Our core business is still automotive, but two of the 10 new customers that we brought on [in the past few years] are commercial truck companies… We are selling exterior chrome mirror shells to Paccar, Daimler, Navistar, and Volvo, as a Tier Two supplier in that market,” says Hitch of the commercial truck sector. “We wanted to diversify our customer portfolio and add more customers. It made sense, given our capabilities and the parts we can chrome plate and decorate.”

While the client base has grown, almost all of LP+P’s customers are based is North America—which makes sense, given that it is located in Michigan, the historic epicenter of the U.S. automotive industry. Some automakers and part manufacturers have moved offshore, but the company retains a lucrative business with domestic clients.

Hitch says he does not typically attend trade shows to drum up new business; instead, the company’s recent growth has largely been accomplished via “market knowledge and aggressively going after new business that would be conducive to LP+P’s capabilities,” he says. New customers, such as the commercial truck companies now working with the company, were lured through strategic sales outreach efforts, not a flashy marketing campaign, he shares.

Indeed, all clients appreciate LP+P’s reputation for quality work. Lapeer has International Automotive Task Force (IATF) 16949:2016 certification for the production and decorative plating of plastic products, and the company maintains a series of quality objectives including on-time delivery, maximizing machine efficiency and productivity, and reducing waste and plant scrap. Continuous improvement is another goal.

“We want to be the supplier and employer of choice. We want to be the one that people choose when they need a decorative emblem or a trim piece, so we try to deliver the highest quality,” states DuBreuil.

As for being an employer of choice, LP+P is both an equal opportunity company and a place where internal promotion is the norm. “We try to promote from within when we can. We take entry-level team members and we train them in-house and move them up. Almost everyone here—our supervisors, our auditors, our technicians—all started at entry-level. So it’s definitely a place where someone can start with a limited skill set, learn on the job, and grow,” he says.

For all its success, Lapeer Plating & Plastics has also had to deal with challenges along the way. Like other Michigan firms, it was forced to close for a time due to a mandatory shutdown order when COVID hit in 2020. There were some proverbial silver linings amid the gloom, however.

“On a positive note, COVID did teach us to diversify our workforce quite a bit,” DuBreuil recalls.

After finding it difficult to attract new hires through traditional means, LP+P turned to “other avenues of recruiting.” The company partnered with organizations such as Goodwill, Job Corps—a nationwide career training program run by the U.S. Department of Labor—Michigan Rehabilitation Services (MRS), and the Lapeer County Community Mental Health agency to bolster its ranks. In a progressive move, the company accepted workers with mental disabilities or other challenges. Lapeer Plating & Plastics offered in-house training and arranged part-time or limited-hour schedules to fit the needs of workers it drew from community organizations.

For these efforts, it was recently honored at a ceremony in Lansing, the state capital of Michigan. LP+P was given an award from state legislators for its work helping clients from the Lapeer Community Mental Health agency and similar organizations.

In total, the firm has “just over 200 employees,” at present, up slightly from the tail-end of the pandemic, says DuBreuil. As for new hires, “I look for a positive attitude and positive energy and a willingness to learn. Most of the entry-level jobs here aren’t too difficult; experience helps but it’s not necessarily paramount… we’ve actually had quite a bit of luck being people’s first-time employer—kids fresh out of high school, recently graduated from college, attending college. We’ve had a lot of luck training them in-house, having them grow,” he continues.

Into the future, LP+P is “looking at upgrading our paint facility,” but is otherwise content to focus on its existing markets, says Hitch. The company’s focus on the automotive and, to a lesser extent, the transportation markets is based on a simple economic reality about mass production. “Our business is really suited to high-volume applications… So we’ll stay in automotive and look to complement our business with the commercial truck sector.”