When designing buildings that leave a lasting impression, the look and quality of entrance doors can make or break the look of any façade. Building codes are becoming increasingly strict concerning energy preservation and safety, so installing architectural doors that perform optimally is a necessity rather than a luxury. Dawson Metal Company’s answer to this modern construction demand is its Transcend thermally broken entrance, launched this March.

Condensation, a major driver behind the limited lifespan of non-thermally broken doors, is caused due to the deficit between interior and exterior temperatures. Metal frames typically lose heat while condensation causes frost formation, which means that much more energy is needed to keep room temperatures stable. Melting frost also causes complications and increased cost of ownership with floor and hinge damage. Dawson Metal Company’s Transcend thermally broken entrance makes complications from water penetration a thing of the past.

While the race has been on to improve on the only existing solution for thermally broken doors which typically relied on lightweight metal components, Dawson’s Transcend thermal break system is based on Azon structural thermoset polyurethane which is cast using state-of-the-art technology that turns this engineered composite material into the main insulator within the frame system.

That is because the thermal break prevents condensation between inside and outside panels. The structural thermoset polyurethane component also acts as the frame to which a laser-cut door pan is custom fitted. Therefore, the polyurethane component acts as a non-conductive thermal break, preventing internal temperatures from transferring from the inside panel to the outside panel and vice versa. Part of the company’s innovation in which these polyurethane breaks are used is the seam-free frame faces and door surfaces on all Transcend thermal entrances.

These highly engineered doors also ensure best-in-class thermal efficiency with thoroughly tested specifications never seen before in the industry. To ensure that clients get only the best value for their money the product will soon be submitted for external testing with an independent certifying test agency for ASTM E283-04 standards, NFRC 100 thermal U-factor, and further performance tests. As a result, buildings fitted with these modern, thermally broken doors are guaranteed to preserve ambient room temperatures.

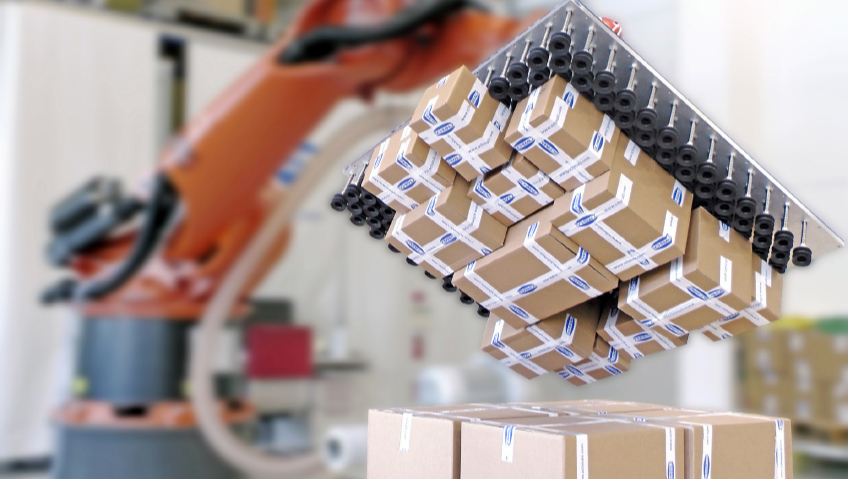

Arriving fully assembled and ready to function, the factory-glazed doors can be unwrapped and installed without any hassle whatsoever, meaning less time and money expended. The full-height architectural doors are installed swiftly with factory-fitted tubular push/pull sets and panic devices, plus completely welded seams.

The process of procuring and installing a Transcend thermally broken entrance could not be any easier and guaranteed consistency gives peace of mind. Dawson will assign a dedicated project manager from the inception of your project through approvals and fabrication. A Dawson Engineer is always available to offer real-time support.

For professionals in the field who know just how frustrating installing such doors can be when working with companies whose processes are typically more time-consuming and less sophisticated, working with Dawson Metal Company is always a pleasure.

Dawson Metal Company built its reputation on much more than superb quality and the latest technology. Instead, the success of its architectural doors also revolves around innovation. The company has earned its merits one high-performance custom design at a time, and its impressive selection of fully-assembled, ready-to-install products that reduce energy consumption and installation time are offered at a price that suits. Choosing these heavy-duty, high-performance, entrance doors does not include sacrificing aesthetics or energy efficiency.

Based in Jamestown, New York, this fabricator is known for some of the most beautiful main entrance doors to some of the United States’ oldest, most treasured buildings. It was also responsible for the doors on the façades of the Museum of the Bible in Washington and many others.

Beyond home soil, its doors remain popular across the Middle East, with oversized stainless steel doors installed in a famous hotel in Riyadh only a few years ago. More custom-made pieces feature in the home of the Emir of Qatar and at King Fahd International Airport in Saudi Arabia. Elsewhere in the world, its doors can be found at the United States Embassy in Beijing and several buildings in the United Kingdom. The Mormon Church is another of its largest clients, favoring the bronze temple entrances for which it has become known.

“We are proud to bring this industry-leading entrance series, which represents the culmination of our decades of experience in architectural entrance design and manufacturing, to market,” says David Dawson, CEO and President of Dawson Metal Company. “The Transcend entrance series is a game-changer for the industry, and we are confident that our customers will be delighted with its performance and aesthetics. We look forward to seeing it grace the entrances of buildings all over the world.”

After 77 years in business, Dawson Metal Company knows what works. While many American fabricators off-shored their plants in years gone by, Dawson and its doors have stood the test of time on home soil.

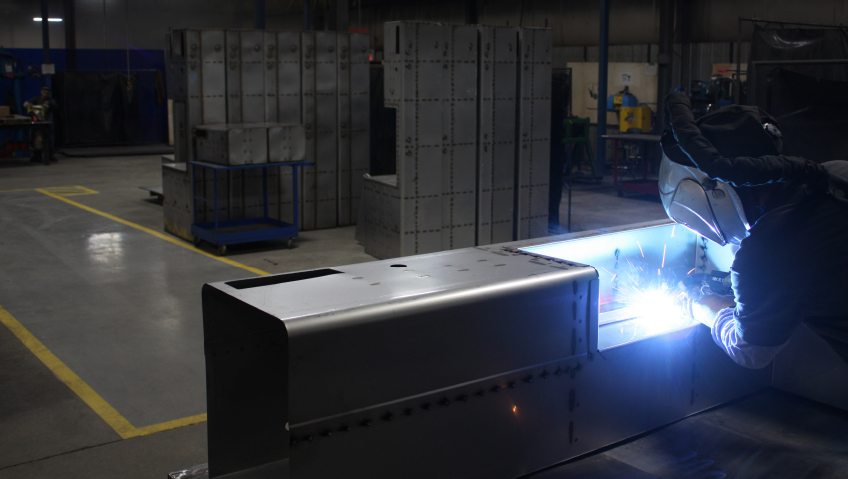

“Dawson Metal Company is one of only a few fabricators globally who can accomplish the level of complex engineering and close-tolerance fabrication that our clients demand,” said Dawson in an interview with us in 2018. “The company fabricates and forms the metal into high-quality architectural products in our door division and custom enclosures in our industrial division. All aspects of our business specialize in solving challenging projects to meet customers’ specific and demanding requirements.”

The company was founded by Dawson’s grandfather, who passed through Ellis Island in 1910 as a 14-year-old from Sweden. After establishing himself as an expert in the sheet metal industry, Mr. Dawson, together with his son George, founded the business after the end of World War II. The father-and-son-duo started fabricating dishwasher enclosures and mailboxes in a 2000-square-foot facility with five employees.

George’s son, David, joined the company in 1980 and decided to harness technology to take the company into its next growth phase, never looking back. Reinventing and improving itself and its offering became part of the company’s fiber.

One of the company’s strengths is the generational knowledge of its loyal and dedicated team of 100 professionals. Their tenures are typically long, as many employees remain with the company for their entire working lives. That is a trend that the firm is working hard to continue.

As energy compliance codes become increasingly stricter across the United States, especially in cities like New York, the company sees its business continuing to expand considerably. In response to the call, it is committed to developing its range of proprietary products and capabilities and investing in technology that saves time while guarding quality. The company is also expanding its thermally broken range of doors which will all continue to be submitted to the rigors of in-house testing before being tested by independent certification authorities.