One can tell a lot about a company by the company it keeps. When vendors become customers and customers become vendors, as they do at John W. McDougall Co. Inc., it demonstrates that premium solutions and customer satisfaction are paramount here. The processing division of John W. McDougall Co. Inc. is home to in-depth fabrication expertise which has customers, from across the United States and further afield, returning for more.

From its base in Nashville, Tennessee, John W. McDougall’s processing division is the dynamic, ISO 9001:2015-certified metal fabrication division of John W. McDougall Co. Inc., a firm with a breadth of talents. With an impressive selection of metal fabrication services for the architectural world and many other industries, this team is well-versed in bringing together insights to give customers options that its competitors often cannot.

As a proud American manufacturer, John W. McDougall prioritizes supporting suppliers that add value to metal on home soil whenever possible. It collaborates with customers whose services enhance its metal processing capabilities, providing access to more and better choices. Beyond its integrated and sophisticated architectural metal façade sister division, the company’s metal processing facility includes a well-equipped contract manufacturing outfit providing premium, custom metal components to individual clients who typically approach the company with fully developed designs in hand.

The processing division serves the company’s architectural division with premium metal manufacturing, bringing a thorough understanding of hurricane ratings due to working regularly with Florida’s building codes. This remarkable knowledge base and its access to private laboratories for product testing creates a process of system improvement that strengthens both departments as each evolves to benefit the other, giving the processing division a significant head start over competitors.

“You call us with a problem—whether it be unique part [needs] or if you’ve had a poor experience with a different vendor—and we’re going to do everything we can to bring you into our culture and offer you a solution,” says Michael Schneider, Senior Sales Engineer.

Efficient and eco-friendly

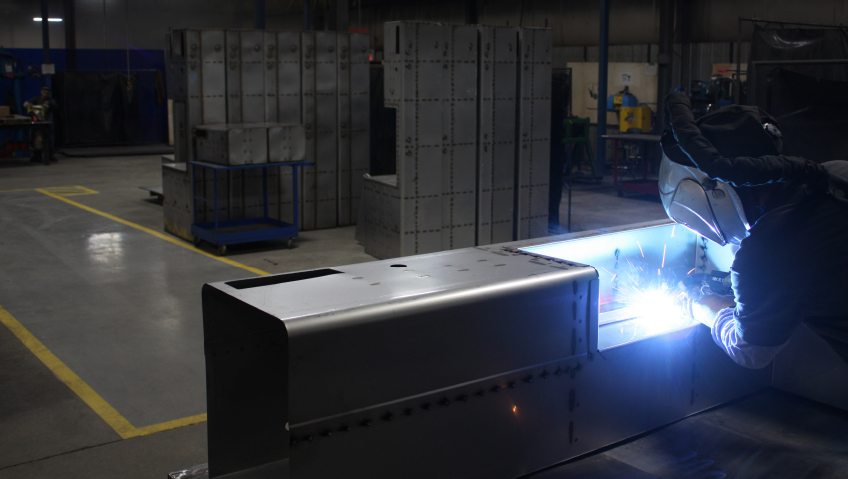

Continuous evolution is, therefore, at the heart of the entire company’s success. In keeping with this culture, the processing division established a state-of-the-art 20,000-square-foot powder coating facility in 2022. This addition to its laser cutting and welding capabilities means that the company has gone from supplying only untreated components to delivering fully finished, packaged metal products ready for installation.

The AAMA2605-certified, eco-friendly powder coating allows customers to ditch toxic liquid paints in favor of a higher quality option featuring outstanding durability. That is because fired powder coatings form a highly protective shell around metal while offering improved value. Together with these benefits, preventing the waste typical of traditional spray-on lacquers results in greater efficiency.

And the company does more than invest in improved paint technology to lighten its environmental impact; it also insists on using recycled metals where possible. “We do everything in our power to ensure that we purchase post-consumer aluminum. Instead of being extracted from the Earth, these materials are recycled, reprocessed, and reintroduced into the supply chain,” says Schneider. In addition, the company aims to work with LEED-certified vendors.

Naturally, speed matters, as does problem-solving. “If you’re having problems forming a piece of metal or finding a partner to form metal, laser cut metal, or transform it in any way imaginable, you pick up the phone and call me. We can see if we can assist,” Schneider continues. Working with McDougall means that metal fabrication issues are solved immediately while, at the same time, the company’s team integrates with customer operations as a seamless addition to their supply chain.

Full processing capabilities

Achieving this symbiosis requires nurturing collaborations based on a complete knowledge of the unique demands of each customer. This goes back to the process division’s inception, beginning its life in 2019 with only a tube laser and a vision of earning $400,000 in revenue with a new focus on tube and precision sheet metal fabrication. The division is proud of the $12 million it invested in creating the next-generation facility as it exists today and the $25 million goal it set for this year considering the 40 percent annual growth it has achieved in recent years.

Today, the division boasts a comprehensive range of sophisticated equipment ready to roll out whenever customers need it. John W. McDougall’s processing division is known for keeping its equipment on par with the latest machinery available. “There is no hesitation by the ownership to invest in the company to keep us on the cutting edge,” Schneider says.

In light of these investments, the team works hard to ensure that its machines run to their full capability and capacity, and finding new ways to improve performance is considered a matter of pride. As such, its most popular high-volume, low-lead time services include tight-tolerance punch and die metal forming and its modern powder coating applications. Besides outstanding metal fabrication, the company also offers metal treatments like precision plate rolling and leveling.

Certainly, innovation is nothing new here, with the parent company having a long history of courting unusual projects. After more than 85 years in the industry, its founder, whose name the company still carries, could not possibly have envisioned the remarkable collection of laser machines—including an automated Trumpf 7000 combination laser punch machine, three Trumpf punches, a robotic welder, multiple manual weld stations, two computer numerical control (CNC) routing tables, two tube lasers capable of processing a 10” diameter round, three 10kw fiber lasers, and seven press brakes—and sophisticated finishing equipment the company owns today.

Building a culture

The team considers its relationships with customers, vendors, and its roughly 150 employees equally important, and so it makes certain that its people hold the certifications needed to excel at their work. One example is the company’s welders, all qualified under the AWS D1.1 Structural Steel Welding Code which guides them to observe top quality and safety standards in the field. This is an aspect of the company’s culture that is considered key to healthy professional relationships.

“I would say it all goes back to culture and respect. That is why people love to work here; that is why people love to work with each other,” Schneider says. “Having a team of dedicated individuals who are committed to our customers’ success just as much as our own means a lot.”

With the processing division always prepared to upgrade equipment to remain at the leading edge, this is advantageous for employees looking to advance their careers in a company that defies stagnancy. The cleanliness of everything—including restrooms—also illustrates a keen attention to detail.

To further show the leadership’s appreciation, staff members are taken good care of with remuneration packages that include tuition reimbursement and paid time off that allows employees to do their part for community charities on company time. “The management team does a great job of understanding the strengths and weaknesses of everybody that works here,” Schneider adds. Because of this, people can positively develop themselves with the support of John W. McDougall, to their benefit and the company’s.

People are heard and encouraged to provide suggestions for improvement, resulting in safety and efficiency being cultivated across all operations. In addition to giving staff paid time off to volunteer, the company has raised funds and awareness for addiction recovery for more than 50 years. In 2023, however, it increased its efforts, introducing an exciting new event. The company raised more than $30,000 in aid of Cumberland Heights, a local addiction treatment center, at its first Swing to Save golf day in September last year. The event is set to be repeated this year, with the company looking to make this a tradition. Interested people are welcome to donate or to become event sponsors by contacting John W. McDougall Co. Inc. directly via its website.

Growing together

John W. McDougall takes its annual business analysis process seriously, plotting its future growth with precision. The process is vital for achieving its goal of $40 million in revenue over the next five years while minimizing bank dependency and keeping its company culture intact.

“We are not going to sacrifice morale or culture for growth. They go hand-in-hand… while we project toward the fourth generation of family ownership in the future,” Schneider assures us. By learning from mistakes, being prepared for the future, and working hard, this team knows it can overcome any challenge.

To this end, satisfying customer needs within a lean and well-run operation is the guiding principle for taking the firm forward. While Schneider points out that metalwork, in its essence, has not changed much since its invention, he believes that new technology drives the art in modern times. By translating its lightning-fast, targeted response into meaningful customer benefits, John W. McDougall Co. Inc. is paving the way to undoubted longevity.