In just a few years, Champ Industries has seen a great deal of change come its way thanks to changes within and outside its walls. It currently has locations in Canada and the U.S., in Winnipeg, Manitoba and Jamestown, North Dakota respectively, and is doing better than ever with a renewed focus.

Since the company’s previous feature in Manufacturing in Focus in 2019, it has welcomed Kevin Medwick on as President and General Manager, a role he began in January 2022. Before his appointment, Medwick had been running a competitor and was subsequently headhunted for the executive position. He is now leading this renowned metal fabrication business that performs fabrication and assembly for original equipment manufacturers and Tier One suppliers across North America.

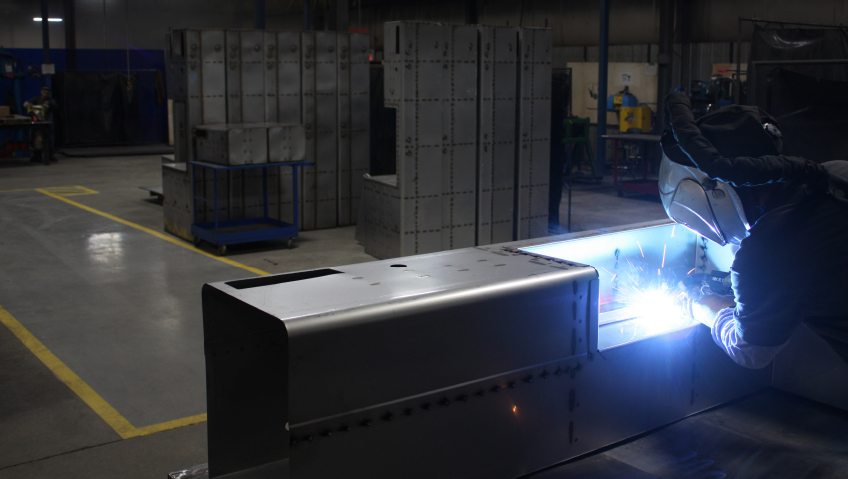

Champ constructs complicated metal assemblies in various ways. Its services include medium-to-high-volume fabricating and assembly of common and stainless steel, aluminum, carbon steel sheet, and tube metal, including laser cutting, forming, welding, assembly, and painting. Typically, customers are not just looking for cut and bent metal, but also parts and completed assemblies that go right onto their equipment.

Because of this, the company must keep ties with a vast network of companies on which it relies to do things outside its purview, and to supply difficult subassemblies for equipment, from across North America or even as far as countries like Japan. A lot of intricate hardware is required in these assemblies, so these networks afford Champ access to what it needs.

“Today, people require high-quality and on-time service, [which is] what we look for in our vendors,” says Medwick. Champ Industries’ commitment to these attributes has allowed it to forge its strongest and longest-lasting relationships.

In the past three years, and in Medwick’s time as President, Champ has increased its bottom line by about 120 percent, which he says is largely due to efforts in customer diversification. As recently as five years ago, prior to his appointment, the company would have been primarily tied to one large customer in the transportation space. Now, it sports three large customers and 10 medium-sized customers across more varied segments like rail and agriculture.

Medwick says that a highlight of his time so far has been acting on the ability of the business to target clients who are having difficulty finding skilled trades in their market, such as small-to-medium-sized agricultural companies in small cities. The company is pleased to produce metal parts for these smaller outfits so that clients can focus on assembly. The approach lets its clients focus on what makes them great, which allows Champ to do just the same in the metalwork industry. Champ endeavours to understand each client’s business to come up with the best cost and manufacturing models that marry the intent of the client and itself. This has allowed it to forge the strong business relationships that have been its hallmark for over 50 years now.

“Champ does a tremendous job understanding what customers need and how they need it,” he says, and this is particularly true because it operates in an industry where quality and timeliness are coveted values for a contractor. One of the ways in which it achieves this is through prototyping and working with a client’s designs and engineers to prove their concepts before production starts.

Relationships have always been valued at Champ, whether with clients, the workforce, or even the nearby citizens of its local areas. Medwick believes that a big reason why the company is so successful is because of the superb group of people in its workforce who all boast a deep knowledge of both the industry and the customer base. About 75 percent of the workforce has been with the company for five years or longer, with 30 percent of those having a decade or more of tenure, figures that are rarely seen at a contract manufacturer.

“I’m still blown away by the level of people we have at Champ,” he says. It is never far from mind that the reason for the company’s success is the people within it, and they need to be looked after in every respect. In turn, Champ and its people seek to look after their local community through philanthropic efforts, usually involving events and donations to local charities and worthy causes. A recent example saw the workforce donate to the children’s hospital toy drive at Christmas.

As Q1 2024 progresses, Medwick shares that operations are extremely busy, especially in the United States and the company’s North Dakota hub. Since clients are based in North America, there can be instances of slowdown here and there, but Champ itself is not seeing any pause in its processes; in particular, its U.S. customer base continues to grow, with massive demand only increasing.

“If you can deliver what you say you’re delivering at a high quality and on time, those customers are going to be happy,” he says.

However, obtaining skilled workers is still a challenge for the business and industry-wide. Medwick says that, if one is willing to work hard at addressing the problem and understanding the market and what it is looking for—appropriate wages and working conditions—the workers are still there for employers to find. Just last year, Champ was able to recruit 25 welders to support a customer within three months as a result of this dogged approach, and Medwick says that Canadian immigration programs have been a big help in bringing in more skilled trade workers on board. The company has never been afraid to put in the necessary work to meet and exceed its goals in every respect.

The bulk of 2024 will see Champ investing in its operations, including changing equipment in preparation for a further focus on automation. The company is keen to begin automating its cutting, bending, and welding processes in the face of potential difficulties in talent recruitment, but the process of automation takes a lot of effort and expense to do properly. A business embarking on automation must ensure that it is learning from the successes of others that have taken the plunge, and the equipment itself requires appropriate due diligence to make sure that every dollar is spent in the right place.

Medwick affirms that, over the past two years and counting, leading Champ Industries has been a tremendous experience for him. A skilled team and a keen focus on the customer serve to further galvanize the company’s purpose, ensuring it stays as strong as the metal it works with.