Specific Mechanical Systems Ltd., a Victoria, British Columbia-based company that designs, manufactures, and installs brewing and distilling equipment, has expanded its automation processes and market reach since it was profiled in November 2022 in Business in Focus magazine. In the face of significant technical challenges, the company has automated its already innovative distillation system.

“We’ve had in-house automation for years, primarily on our brewing systems, but now we’ve developed the same thing for continuous columns,” explains Operations Manager John Leask of the technology for distilling spirits.

Specific Mechanical Systems created a continuous column distillation system that represents a significant advancement over traditional column still designs and offers a more efficient distillation process when compared with pot still distillation. While spirits are commonly produced in single batches via a time-consuming start-and-stop method, the continuous column system allows for uninterrupted flow. The company’s novel automation system has now made this speedy distillation process even more efficient and productive.

“Essentially, you can produce any type of spirit on the continuous column still. Customers will potentially prefer to create certain types of spirits on more traditional pot stills but, in terms of general distillation principles, any spirit can be produced on a continuous column still,” notes Sales and Marketing Manager Chad MacIsaac.

To automate its continuous distillation process, Specific could not rely on the same procedures and equipment it utilized to automate brewing. “There are some similarities for sure between what our automation system for the brewing and distilling will look like and perform like, but functionally, they are different systems and different processes,” says Leask.

Unlike typical brewing systems, distilleries operating continuous column stills often utilize extremely large equipment. To complement its continuous column stills, Specific Mechanical fabricates large stainless steel tanks that can accommodate thousands of litres of liquid. The column stills used for continuous distillation can be “anywhere from 30 to 70 feet tall,” he adds.

Continuous distillation systems are enormous. “Many of them are never actually fully assembled at our shop. They’re built and tested in sub-assemblies and are then fully assembled at the customer site,” Leask says. By contrast, “breweries aren’t that tall; we can set the whole thing up in our shop and test the complete system working on our shop floor.”

Brewing involves significant concentrations of water, and the sensors and testing devices used in the brewing process cannot always be used for distilling, which involves significant concentrations of ethanol. For a start, most ethanol testing equipment “needs to be explosion-proof rated. That cuts down your options dramatically,” he states.

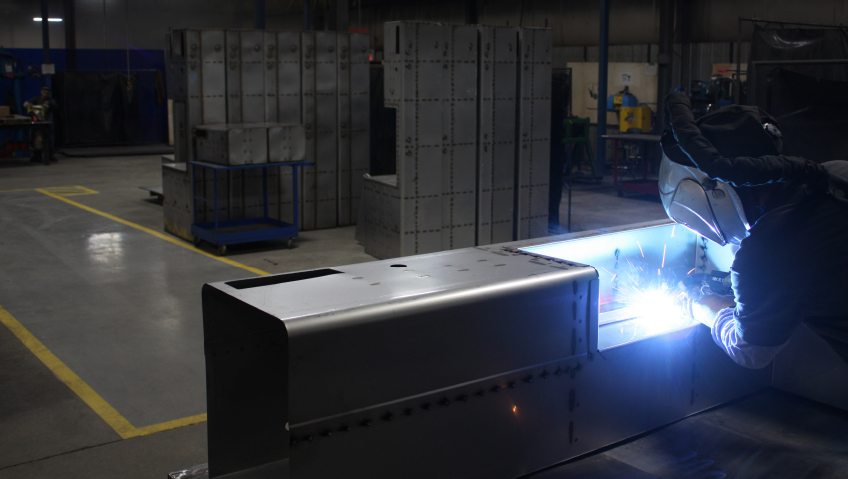

Yet despite these difficulties, the in-house automation team prevailed. Automated continuous column distillation is the latest example of the company’s successful do-it-yourself approach. Fabrication, manufacturing, design, and automation work is performed in-house, and Specific Mechanical also continues to emphasize research and the development of new equipment and new processes.

Forward-thinking and innovative as it may be, the company retains an old-fashioned artisan pride in its work. “Every system is customized,” says Leask. “Of course, we have some templates that we draw from but, at the end of the day, every system is customized to suit the customer’s available space, ceiling heights, their process, what products they’re hoping to distill or brew, and their budget.”

Besides brewing and distilling equipment, the company designs and produces pressure and food processing vessels, wastewater tanks, stainless steel tanks, and other gear. Its products are used in wastewater treatment, oil and gas, other food and beverage markets, and pharmaceutical production, and the company has also been involved with battery technology for electric vehicles, according to MacIsaac.

“Without naming names, there are a handful of companies that are advancing battery technology in North America,” he says. “In the process of improving range, they’re looking at optimizing battery performance, and that involves fluid transfer, fluid storage. We provide the processing equipment to help in that regard.”

The company employs approximately 85 people at its Victoria operation. Another 35 people work at a facility run by the firm in Nevada. Job applicants need to have skills, experience, and a team player outlook.

“The right technical training is important, whether that’s someone on the shop floor in the trades—welding, machining, sheet metal, et cetera. On the office side, we’ve got engineers, project managers, et cetera,” says Leask, noting that the appropriate education and experience for those positions is required. “Beyond that, I think one of the biggest things we look for is somebody who is going to be a good fit with the team. We really promote teamwork, and that kind of comes through with our culture.”

In addition to a collaborative approach, this culture is all about quality and customer service. This includes “being available, being friendly, and being pleasant to deal with so people want to come back and work with us again,” he says. Those customers range from small craft brewers and distillers to huge corporations, including beer giants Labatt and Molson.

Though eager to expand the business it does with top brewers and distillers, Specific Mechanical has not lost touch with its roots. The firm was launched in 1984 by Bill Cummings and Philip Zacharias, long-time friends with backgrounds in machining and welding. At first, the pair built brewing systems for clients in Victoria, and it grew from there.

“Our company is different from many companies that compete in our space because we’re local. We’ve been around 40 years. We were started by two people,” states MacIsaac. “The values of a small company remain strong as we grow. We try to make sure every new employee who comes on understands and recognizes it. It’s really important for us to convey that message to customers so they know they are dealing with real people… and together, we’ll both be successful.”

To help ensure client success, Specific offers global installation services. “While our primary market is North America, our field service team is capable of doing installations worldwide,” says MacIsaac. “We’ve just delivered a very large system to Argentina, which will be the first large craft distillery in Argentina. We’re delivering a system to Rwanda, which will be our first system into continental Africa.”

The company provides both remote and in-person support to clients looking for guidance in setting up their equipment or dealing with problems.

Given that most of Specific Mechanical’s equipment is geared toward the beverage market, customer support is complemented by a commitment to quality. It has certifications from UL and Underwriters Laboratories of Canada (ULC), and the company’s pressure vessel design and manufacturing capabilities have been certified by the American Society of Mechanical Engineers (ASME).

“There’s a pretty rigorous quality program in place to support that. Any ASME pressure vessel must be registered with the provincial government, if it’s in Canada. In the U.S., it’s called the National Board. There’s documentation, testing—numerous steps that have to be taken for those vessels. We have all that in place and have for many years,” says Leask.

Currently, the company is in the process of establishing an online store. The intent is to make its wares more easily accessible and available.

“Some new products lend themselves a little better to putting on an e-commerce site—not so much custom systems, but some of the more product-based things we have. For example, a keg washer. We have various pumps and things like that that we frequently sell, and we can put those up on an e-commerce site, and we’ll see how that goes. If it’s successful, we can keep building the inventory of what we have for sale.”

The team has not forgotten the importance of the human connection, however, and representatives routinely attend trade shows across North America.

Despite all this upward momentum, the company still faces its share of challenges. The pandemic’s lingering impact has resulted in price hikes for supplies, components, and other gear. At the same time, Specific Mechanical faces competition from overseas manufacturers who can offer lower prices for their systems. These lower prices, however, are more than offset by Specific Mechanical’s quality and customer service. Well-made equipment and prompt client care mean fewer maintenance and mechanical hassles in the long run.

“Price is obviously a key buying factor in any decision, including capital expenditures, but total cost of ownership is probably the most important component to consider. That’s how we differentiate from others, and we try to convey that message every day,” says MacIsaac.

If anything, the company is keen to increase the amount of business it does outside of North America. Going forward, “expansion into new markets geographically will be a focus for us,” he says.

Leask hopes that Specific Mechanical experiences “an increase in market share, particularly in the continuous column space,” over the next five years while “offering larger systems and having the capacity to build physically larger tanks and equipment.” Growth is on the horizon, and the future looks bright for this constant innovator.