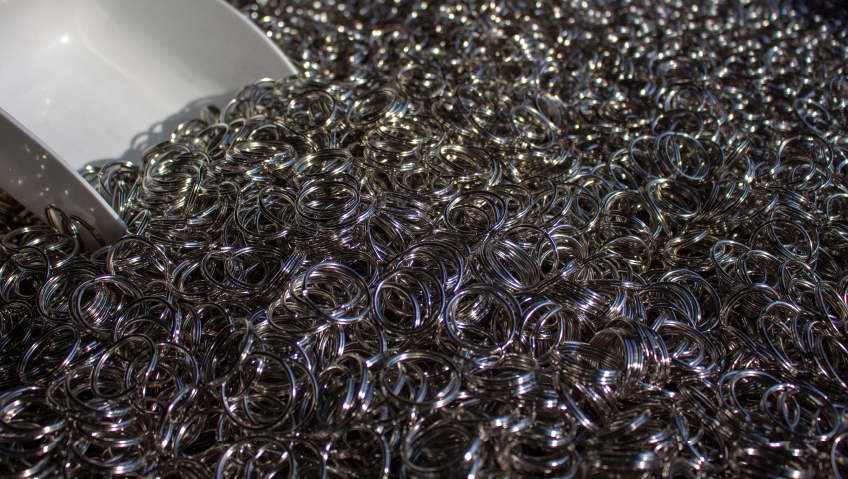

A+ Group has been providing manufacturers with plastic and metal hardware for a quarter of a century. Armed with an extensive inventory and multiple distribution centers, the Marlboro, New Jersey-based business represents some of the world’s leading manufacturers including Fidlock, Bodypoint, Systemmag, Trimmers, and Winhigh, in addition to supplying a standard hardware line.

Business in Focus featured A+ Group in 2020 and recently sat back down with the team to catch up on the latest developments. Not surprisingly, COVID was a major topic. Disruptions to the supply chain were a particular challenge for the company as they worked to supply their U.S. manufacturer customers during the shutdown. To make matters worse, the pandemic hit around Chinese New Year, which is already a challenging time due to month-long holiday celebrations in China. “So we had those normal challenges, and now you have ports closed down and factories closed down,” says CEO Elizabeth (Betty) Matlaga.

Despite the global shutdown, “we actually didn’t see a lot of slowdowns in the beginning because in 2020 during COVID people didn’t know what was going to happen with the supply chain,” Matlaga recalls. This uncertainty led customers to stock up as a precaution. “So once our supply chain got back on track we actually had good sales because people were concerned it was going to shut down; they were over-ordering.”

Business slowed down in 2021, “because things didn’t come back as fast,” Matlaga says. A+ Group supplies components used for events such as trade shows, proms, and sporting events, which were still canceled for much of 2021. And, after stocking up in 2020, customers had the inventory they needed.

Fortunately, A+ Group was flexible enough to take business in a new direction. “We shifted very quickly into PPE,” Matlaga says.

Fidlock Brand Manager Barton Burdette adds, “When COVID hit, everything went dead quiet for several weeks and we scrambled to find other industries and avenues we could get involved in.” Facemasks provided an immediate solution.

“When this all happened, overnight [there was a] demand for face masks,” says Bryan Collins, Director of Sales and Marketing. “Every person in the world, essentially, needed a few of them. Obviously the supplies for those masks didn’t exist. What was interesting was that the cottage industry of the U.S. manufacturers actually all came together to increase the manufacturing ability of these masks, to meet demand. So what we were able to do from a supply standpoint was start giving them the raw ingredients, the materials to produce the masks. So that was cool, to see the community of domestic manufacturers come together to meet that demand.”

In addition to moving into new product areas, the team increased their focus on COVID-resistant industries with which they were already involved. “A big part of our business is the outdoor industry and that self-recovered immediately,” Burdette says. “So where we lost business, we gained a lot of new business in other areas.”

The team put a great deal of effort into supporting their vendors through the tough times. “We proactively worked on our relationships,” Matlaga says. “We said to ourselves, ‘how do we give that vendor business? They’ve been a good vendor. We don’t want to lose being with them.’”

The company’s commitment and support extended to employees as well. “We’re really proud of the fact that… we are really attuned with people’s lives,” Matlaga says. Before any word of a shutdown, the team planned ahead and ran the numbers to ensure the company could stay afloat if the pandemic affected business. “We made an announcement to our staff that we were committed to no layoffs and no salary reductions,” Matlaga says. “We didn’t cut back one employee over COVID.” In addition, the company ordered hard to find PPE products for employees to use for free. “We were doing things to keep people calm,” Matlaga says. “What we were saying was, ‘don’t worry, we’ve got this. We’ve got the financial stability and the company. You worry about your family.’”

A+ Group upheld their promises to employees throughout the pandemic. “We haven’t reduced anybody’s pay,” Matlaga says. “The company stayed very financially secure. We went after everything the government was offering and got it… we never closed one day and we had no reductions so we are really proud of that,” she shares.

“One of the reasons why we remained financially stable through COVID… is the fact that the philosophy here is to behave like you’re in a recession,” Matlaga says. “In other words, go after recession-proof industries for selling and be lean all the time.” So, when COVID hit, “we were more prepared than other people, probably because we didn’t have to start cutting fat – because we didn’t have a lot of fat,” Matlaga says.

The lack of trade shows during the pandemic “reminds you of how important it is to have face-to-face visits with customers,” Matlaga says. But, even though trade shows and other events are “picking up” now, she expects to see a “new reality” post-pandemic. Matlaga anticipates travel to become more “deliberate” and “intentional” rather than the default expectation.

“I think what we all learned is, do we need to travel as much?” Matlaga points out. “Do we need to spend so much money on trade shows? I think everybody’s looking at that. So things are shifting in our world. But we’re picking up other business because we have good partners. Our customers pivot really nicely.”

One of the company’s most exciting new ventures is a web store where business-to-business customers can purchase products directly. The process will be “much quicker and easier” now, says Collins. “We’re excited about that because we are really the first in the industry to offer that type of service.”

Adding a convenient, easy to use online purchasing option was a natural development in the age of COVID. “It really came to light with COVID [as] people started relying on more digital solutions,” Collins says. “So we looked at it and said, ‘how can we make the buying process even easier for our customers and maintain our position as an industry leader on that front?’ And the only thing that really made sense was a very intuitive and easy to use web store where they’ll be able to go in, browse our products, and buy point of sale. We’re really the only ones in our industry who are going to be offering that.” The web store will go live by the end of this quarter.

In another exciting development, A+ Group is taking on product design. “We really built out our product development team of designers and engineers so we’re doing not only contract design and development work, but we are really trying to focus in on what we’re calling our A+ Elite line, which is going to be in-house engineered hardware,” Collins says. “In the past we’ve gone out to China and we’ve looked for pretty cool products, but we’ve really left the design process external. We’re making that process internal now because we hear the voice of the customer, and what they want and what they need isn’t always commercially available. So for the first time ever we’re going to have the resources to make them exactly what they need and introduce it to the market through an intuitive platform for easy fulfillment and purchases. We’re really trying to shorten the sales cycle and flatten the supply chain for our customers to give them what they want in the easiest fashion possible.”

With all the new developments, the team is proud to announce that they can now support clients every step of the way, from product development through to fulfillment. “We can do everything – logistics, quality control, assembly, trading in currency – which we couldn’t do in the past,” says Owner and Founder Mike Schreiber. “We’re expanding our offerings and our capabilities to our customers.”

Matlaga explains, “Our goal is to simplify the process for our customers and to have more market share.”

A+ Group wants to be “the voice of the customer,” Collins agrees.

After overcoming the challenges of COVID and introducing exciting new developments, A+ Group is well prepared for a successful future and ongoing growth. But, no matter how much the business expands, the company’s foundational goal will always stay the same: to “supply U.S. manufacturers with fair price, quality products in a timely manner,” Matlaga summarizes.