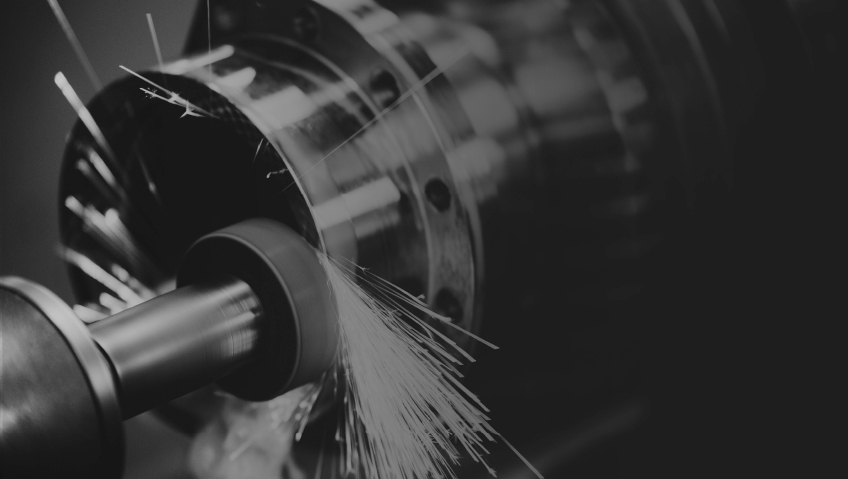

The manufacturing of medical devices takes exceptional care, quality and precision. C-Axis Inc. excels in all three as it builds exceptional critical-to-function components for the medical device industry.

Whether it’s implantable medical devices such as heart valves, bone screws, or cardiovascular and neurological based devices, the company is dedicated to detail and maintains a rigorous quality system. The operation is directed by experts skilled in the manufacture of a variety of complex and challenging components, and in rigorously meeting time and budget constraints.

To serve customers with unvarying efficiency the company’s facilities have been recently modernized, including a new building and renovations.

Founded in Minnesota 1997 by Jeff Haley, C-Axis built a second facility in Puerto Rico in 2004. Since then the business has continued to expand to meet demand from the leading medical original equipment manufacturers (OEMs) around the globe.

With world-class capabilities that, laser marking, laser cutting, and additive machining (3D metal printing). Working include Swiss machining, (three, four, and five axis) milling, micro-machining, CNC lathes, laser welding with customers from development to DFM and full production, C-Axis is poised to grow while continuing to ensure customers are at the forefront of their vision.

“We needed to upgrade our building situation because we needed to double our footprint,” says Dennis Olson, Business Development Director. “We’ve been kind of a smaller player in a mid-size field, and our building is from the eighties. Basically becoming a world-class manufacturer means having a world-class, customer-friendly facility that can allow growth as we add to that capacity and our capabilities.”

The company is also adding state of the art machining equipment, including clean-room capability, to the new facility. In doing so, they’re moving their Minnesota production into the new building while revamping the current facility into a customer interaction center focused fully on R&D and new product development.

“That’s how we’re moving forward as we modernize the company,” says Olson. “We’re separating facilities. That sounds like no big deal, but having the Prototype Center separate from the Production Center allows us to focus on the customer’s prototyping and engineering teams without the worry of interrupting production or fitting small production runs into the large run production schedule.”

This development center will also be branded separately from C-Axis with a new name, C-Axis 360 – Ideas, Iterations and Innovations.

“The idea is that from the initial interaction with our technical sales team you have very customer-focused interactions that are based on how we can help you achieve better speed to market, while at the same time helping you create the best manufacture-able design from the very beginning of the project,” Olson says.

With the updates, C-Axis is set up to help generate technical innovations from early in the process while keeping the manufacturing of production volumes cost effective and enabling clients to be successful throughout the entire process.

“We look at C-Axis 360 as an opportunity for our customers to save weeks of development time by having their project team come into our facility. Here they are assigned a C-Axis team (an Engineer, Technician, and Machinist) to work with to complete multiple iterations in one sitting, helping to improve the R&D timeline. Instead of doing things in series, our customers can do multiple potential design iterations in parallel and save six or seven weeks in their NPD cycles,” says Olson. He notes that this capability is greatly appreciated by clients.

While most of the large medical device OEM companies have the capability to either do this themselves or pay exorbitant fees to have it done, he says that second-tier OEM companies don’t get the same kind of service elsewhere.

“We’re one of the few companies that cater to the smaller companies. My team was just out in California for the MD&M West Show, and we had a line of people very excited about the fact that we’re willing to do this type of service for the smaller medical device companies.”

The best time to take cost out of a product is during the initial design phase. As cost pressures increase in the market, clients who partner with C-Axis during the design phase have access to the company’s technical experts in raw materials, laser welding, various machining processes, secondary processing and assembly, who are well versed in Design for Manufacturability (DFM).

The DFM process allows for a detailed review of the part use, design requirements and tolerances between device designers and the C-Axis manufacturing and quality engineering teams, ensuring products are not only manufactured to achieve the required performance, but are done cost effectively.

The customer experience has always been of utmost importance for C-Axis. Even throughout the pandemic, which greatly affected both labor and some supply chain situations, the customer experience team was available to mitigate those challenges.

“My team has been in front of people for the last six to seven months even though it’s still been kind of a lockdown situation,” Olson says. “We’ve focused our efforts on going to places where that wasn’t a problem. Our main objective of these visits was to continue to provide solutions to our customers’ problems.”

The company’s expertise in 3D printing is another highlight designed to keep focus on improving both costs and lead time for customers.

“While any traditional machining house can basically make prototypes, the problem you run into is the exorbitant cost of setup, and then the time to ‘whittle down’ to your component makes this process more expensive,” he says. “It could be several hours of setup, and another hour to make just one part.”

C-Axis’ GE 3D printer’s process is similar to metal sintering, but layers measure 15 to 30 microns thick. Instead of jetting drops of ink onto paper, the Direct Metal Laser Melting (DMLM) process uses lasers to melt ultra-thin layers of metal powder to build a 3-dimensional object. The use of a laser to selectively melt thin layers of tiny particles yields objects that exhibit fine, dense and homogenous characteristics.

“The other advantage of the 3D additive machine is you can get personalized devices,” says Olson, referring to perfectly sized hip implants. “So that’s where the 3D additive manufacturing becomes more exciting as you move forward. We did invest in a pretty top-of-the-line machine that the FDA has already approved for implant-grade hips, knees, shoulders and those types of things.”

The company is looking to use it in two ways: To improve speed on the front end, and also to do very specific one-off sizes.

“If you try to do that on a conventional machine, you have the cost of doing a setup every time you make a part, and the end result becomes a very expensive implant,” Olson says.

Over the past year, C-Axis has weathered its share of obstacles due to the COVID pandemic. Many of the large OEMs involved in the elective-surgery business space drastically decreased their requirements for 2020 and 2021 or have requested to push existing purchase orders out a year. “We have continued to work with our customers during this tough time,” says Olson.

“The pandemic completely shut down what was supposed to be new business ramping up at the beginning of 2020. This is in large part due to the cancellation of elective surgeries in hospitals and clinics worldwide. Our customers couldn’t get out and train doctors on these new devices and procedures,” he says of the “COVID turbulence” that affected many industries. “At the same time we had other customers in other medical markets that we built components for for many years. The volumes for these devices have remained consistent and steady over those last few years, but with the ‘COVID turbulence’ our customers in these markets forecasted an increased demand that the COVID pandemic would create. We worked hard at the beginning of 2020 to meet this astronomical demand.”

The resulting uncertainty in several areas of the industry meant that C-Axis had to face many difficult challenges and make changes.

“You had to be nimble!” Olson says. “And you had to make some reductions to the workforce even though you didn’t want to. Our leadership team did a 30 percent reduction of the workforce to maintain viability. There is some good that can come out of this because obviously you had some people you were either trying to train up or wanted to exit out, but we had to focus on what was best for the business long term. This meant we had to put some people on deferral that were very good employees hoping they would still be there when things came back.

“And here we are a year later and we feel like we’re about to drink from the fire hose.”

Now, he says, the challenge is how fast they can meet customer-driven growth numbers and also manage the issues of the supply chain and labor acquisition in the current atmosphere. “It’s forced everyone to be creative and flexible.”

The constantly changing situation has actually helped the company become better, says Olson. “We focused on this C-Axis 360 model at first, because that’s where medical device companies were spending their money – in the R&D space,” he says. “We needed to do better than the competition in the R&D space, because our customers needed it. We focused on this, filling a demand, and brought our customers value; that’s why we are where we’re at now.”

That the company still managed to grow 35 percent last year, and is poised to double its footprint and revenue in the next two years, is testament to the strategic, consistent focus the C-Axis team is putting into addressing their customer’s needs.

Another big change over the last year includes one in leadership: last year Jeff Haley, founder and owner of C-Axis, decided to step down and retire. This allowed his son Jared Haley – an engineer by training and education – to take over as company president.

“We have a strong, well-led company, focused on our customers’ expectations. Jared leads this team with a younger vision and energy to drive our team on how we can strategically grow the business for the future by always finding a way to provide value to our customer base. Through technology and expertise, we believe we can help our customers meet their devices’ clinical innovation requirements,” says Olson.

And when he speaks of what makes C-Axis unique in the industry, Olson mentions the work they do with large medical device OEMs as a very important base for the business. While C-Axis continues to service these customers, they have also focused on the new, smaller to midlevel companies, engaging them with quick-turn capability to do prototyping, DFM, and the ability to help them on the front end of the development process to springboard their products to market. It’s this focus that is truly growing the business the fastest.

Olson says going forward, C-Axis will have a busy journey: doubling the footprint by adding the new production facility in Maple Plain, Minnesota, creating a new campus, and doubling the company’s revenue, all while maintaining the company’s innovative, quality precision work and service in the industry. “We’ve basically created milestones for the next few years by becoming the go-to option for midlevel customers in the medical device space,” he says.