VirTex Assembly Services, Inc. is an electronics contract manufacturing company based in Austin, Texas that provides the full spectrum of design, development, and distribution services to customers across a wide range of market sectors including automotive, defense, medical, industrial control, and more. The company has seven locations, more than 300 employees, and a focus on low-volume high-mix contracts.

~

Established in 1999, VirTex Assembly is approaching its 20th year in business. When Founder and President Brad Heath created the company, his vision was to develop a service specifically designed to support manufacturers with low-volume needs. Larger contract manufacturers are generally structured to support high-volume low-mix orders – long runs of identical components – for their clients. Many OEMs also have low-volume high-mix needs that aren’t easily supported by the systems and procedures that are often employed in those facilities.

Virtex was designed specifically to fill this gap in the contract manufacturing marketplace, and has been very successful in doing so.

In September of 2018, in an effort to expand both its reach and its capabilities, VirTex acquired an electronic manufacturing services company called PPI-Time Zero. Prior to this acquisition the company operated in the Midwest and Southwest United States, and a third location in a low-cost region in Mexico. This new addition brings 100,000 square feet of manufacturing space in three regional markets previously outside VirTex’s territory: Fairfield, New Jersey; Waynesboro, Virginia; and Norwood, Massachusetts. This acquisition has enabled VirTex to not only expand its reach, but also its service offering by incorporating new services such as metal fabrication and wire and cable assembly, among others. PPI has more than forty years of experience serving the Northeastern United States, and this will enable VirTex to build on an existing presence in that region.

VirTex Assembly has seen consistent growth throughout its history, but it is currently in a phase marked by a significant increase over what has been typical growth. The company’s prevalence in the defense and medical sectors in particular has been growing substantially as a result of its shift from developing components toward developing complete solution packages. Indeed, the company has changed a great deal since its beginning as a circuit board assembly company in 1999; VirTex’s focus now is on full package products and systems integration. Consequently, in the last two years the business has nearly doubled in size, from a 45 million dollar company to one valued at more than 80 million dollars.

Today, the company employs roughly 300 people across seven locations. VirTex’s corporate headquarters is located in Austin, Texas and is the company’s largest facility at 65,000 square feet. In Wisconsin, the company has a 60,000 square foot facility that it obtained with the acquisition of MTI Electronics in 2014. This Milwaukee branch of the company is now called VirTex MTI. In Fairfield, New Jersey, two former PPI-Time Zero facilities, now called VirTex PPI, combine to comprise 47,000 square feet, and the remaining two PPI facilities are 41,000 square feet in Waynesboro, Virginia and 30,000 square feet in Norwood, Massachusetts. Finally, the company has a 40,000 square foot location called VirTex AVG located in Mexico.

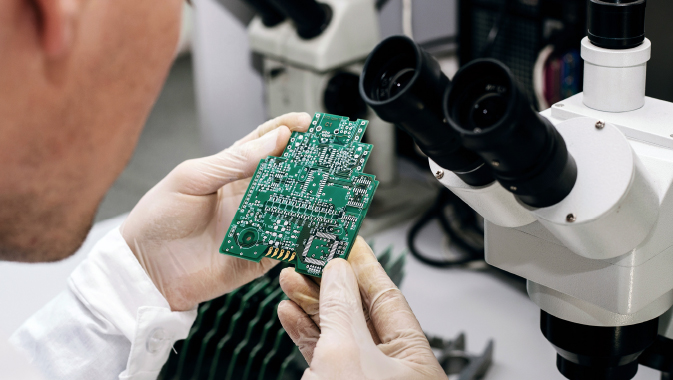

VirTex has established itself as a leader amongst the competition by focusing on developing a reliable, consistent, high quality manufacturing operation that has enabled it to become among the most highly certified of all companies competing in its market sectors. Demonstrating its capacity to manufacture products that consistently meet and exceed regulatory standards as well as the high quality standards expected by its customers, VirTex’s quality management program is ISO 9001:2015 certified. That program has also been certified for defense and aerospace applications under AS9100D, and for the production of medical devices under ISO 13485:2016. Further supporting the company in the development of medical devices is the FDA 21 CFR Part 820 certification. This designation demonstrates that VirTex products meet regulatory standards for medical devices, and enables the company to ship these products directly to end users. This provides a significant advantage over competitors.

For circuit assembly, the company has received J-STD-001 certifications in both Class II – for dedicated service electronic products – and Class III – for high reliability electronics products. These are widely recognized as the preeminent certifications establishing industry standards and best practices for soldering electronic components to circuit boards. This includes understanding what methods and materials should be used in what circumstances, and how to analyze the quality of the interconnections after soldering. These, among many other certifications, demonstrate the company’s commitment to providing the best quality products and services to its customers, and have enabled the VirTex team to secure contracts in many challenging industries with very demanding needs.

Military, aerospace, medical, and industrial customers all depend on the reliability of VirTex products, and the risks involved can be substantial. With lives on the line, there are very high expectations for quality, and zero tolerance for mistakes.

Beyond these extensive qualifications, another way that the company has been able to stand out in the marketplace is by incorporating robotics and automation into its facilities. In contrast to the popular idea that automation will reduce employment, VirTex is committed to using automation in a way that doesn’t limit its capacity to create new jobs. The company’s focus on technology has resulted in it being recognized with numerous industry awards, including the Manufacturing Leadership award in the Enterprise Integration Technology Leadership category from Frost and Sullivan last year. Also in 2018, VirTex was given the Fast 50 award, which recognizes the fastest growing companies in Central Texas, and an INC. 5000 recognition for being one of the fastest growing companies nationwide. This marks the eighth year in a row that the company has won this award, demonstrating nearly a decade of consistent growth.

To be sure, automation has enabled a resurgence of contract manufacturing in the United States, and VirTex has been at the forefront of the effort to make domestic electronic manufacturing competitive enough to capture some of the market share back from foreign producers. Automation and robotics have allowed the company to increase production efficiency, improve the quality and consistency of product output, and provide a level of value that has convinced many OEMs to move their manufacturing operations back to the United States from overseas.

Automation is a great leveler in this way, but it does not work on its own. VirTex has also invested heavily in the development of lean manufacturing processes to eliminate mistakes, defects, wasted time, and wasted resources at every point in its operation.

To this end, the company uses the Six Sigma approach to manufacturing. Six Sigma is a set of organizational tools designed by a Motorola engineer in the 1980s, and is widely used in the manufacturing industry today to achieve data-driven process improvement. Through the implementation of this system, VirTex can identify and eliminate variability in its production, resulting in consistent, reliable output. The team is constantly collecting and analyzing data related to its processes and using that data to drive improvements throughout the company. The result is an operation that is constantly bettering itself and enhancing the value it offers to its customers. By adopting these new technologies, and using data toward self-improvement, VirTex has become a very lean operation capable of competing with contract manufacturers in even low-cost regions.

For two decades, VirTex Assembly has been focused on developing expertise, and has become the most highly certified contract manufacturer of its size as a result. It has evolved from a component producer to a manufacturer of complete solutions by continually expanding its offering to incorporate new services based on the needs of the marketplace. VirTex is committed to continually improving its operation to provide its customers with the best possible value.