Family-owned Weaver Industries has come a long way since its founding in 1954 by Harold S. Weaver as Weaver Pattern Works. Now an ISO 9001:2015-certified and ITAR-registered full-service machine shop, the company specializes in advanced materials like graphite, carbon, and C/C. Leveraging cutting-edge CNC technology alongside manual turning, milling, boring, drilling, and sawing, Weaver Industries also offers comprehensive in-house inspection services, including a programmable CMM and laser scanning capabilities.

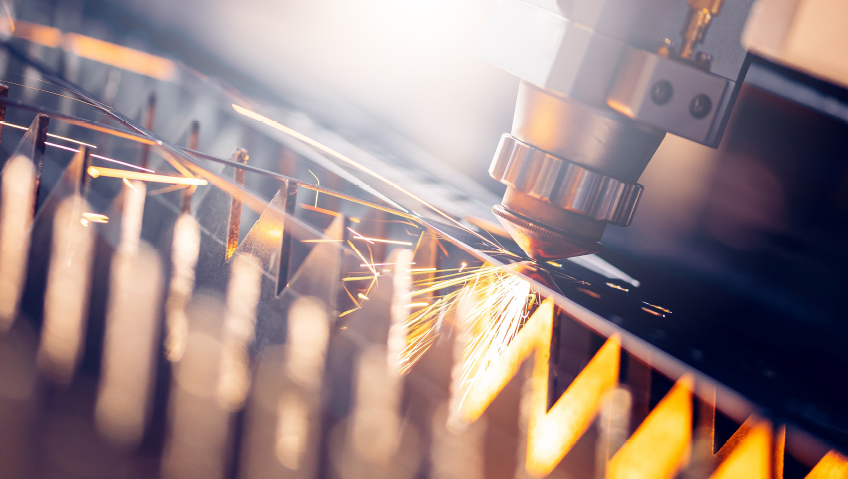

Over the years, technology has completely changed how Weaver Industries manufactures goods and satisfies material requirements. The company offers faster, more effective, and more efficient processes than ever before via state-of-the-art technology, resulting in accuracy and excellence in every project.

“My grandfather started our business 70 years ago as a wooden pattern maker, essentially working for another businessman who was running a family business, where he was the foreman,” says President Jim Weaver. “My grandfather was charged with the task of training the person that was going to take his position, and he was fortunate enough to have a friend who said, ‘if you go out on your own, I’ll give you enough work to keep you busy.’ Three generations ago, my grandfather took that leap of faith and went out on his own and started the legacy that now is Weaver Industries.”

Making patterns in a basement eventually led to the opportunity for the company to machine graphite, Weaver adds. “My grandfather was the individual who started it, took the risk and saw the vision of what this company could be,” he says. “He also, in what I believe to be a very visionary statement, said to employees he saw more of a future in machine and graphite than in the wooden patterns they were making.”

After Weaver’s grandfather passed, his dad ran the business for a number of years before passing away a year before the pandemic, leading to Jim Weaver and his brother Jason becoming owner/operators of the business.

“Looking back at the contributing factors to our ongoing success, first and foremost, it’s our family culture,” says Weaver. “We’re a family business, and have been a family business for 70 years. We treat our people like family members, and that was passed from my grandfather to my father, and from my father to me and my brother.”

Weaver also credits his grandfather with developing the company colors of white and green with a very specific purpose: green for the pastures and fields of opportunity and white for the integrity of doing business with everyone, be that customers or employees.

“We’ve carried all those things forward,” Weaver says. “The integrity we have speaks for itself within the industry. We’ve developed a tremendous name through word-of-mouth over the last 70 years.”

The company also prides itself on having a customer-centric focus. “We’re very good at working with our customers and developing relationships in order to service them the best we can,” says Weaver. “We have a lot of individuals here who understand the foundation of what they do. We have the ability to work through, think through, and tackle problems other companies might not be able to. We also have a lot of experience and understand the materials we’re working with, the industries they’re used in, and how they apply to various applications.”

Sales Manager Kent Manbeck agrees. “In February I will have been here for 35 years,” he tells us. “I started in drafting and got into estimating and project management, and then customer service. I moved up into sales and sales management. As for Jim and his brother Jason, you don’t get the impression they necessarily own a business; they’re not flashy people. They’re very approachable.”

Weaver is emphatic the importance of being a family-owned business and how it shapes the company’s culture. “Each generation has kept the focus on family culture,” he says. “We believe if we treat our employees as a part of the family, it fosters a mutual respect, positivity, and loyalty that go both ways. Not only do we show respect and loyalty to our employees, but they show that same loyalty and respect to us.”

That has resulted in numerous employees being with the company for decades. “We understand the value of that, and the fact that work just isn’t everything that defines you as a person,” says Weaver. “There’s a time for work and there’s a time for family, and we try to accommodate those things for our employees with flexible work hours when needed.”

As President of the company, Weaver makes it a point to get to know all the employees personally. “It goes a long way in trying to help develop a situation where you’re working with friends and figuring things out as a team.”

Over the past decade, one exciting trend in the ever-evolving marketplace has been the U.S. shift toward reshoring manufacturing, says Manbeck. “I believe we’re a part of that movement. And then the alternate energy sector—clean energy, various alternate sources of energy, new materials, and even the nuclear sector—has also seen a resurgence.”

Graphite is found in a variety of industries, he adds, such as machining for aerospace, aircraft brakes, rocket nozzles, satellite parts, and heat shields. “One of the things that we were blessed to be able to take part in was machining the heat shields for the Mars Rovers Curiosity and Perseverance,” says Manbeck.

He adds that 10 percent of the company’s business is custom polyurethane sold to automotive, mining, and farming equipment manufacturers. “It goes into transportation and material handling, everything from amusement park rides to simple sheeting for anti-vibration mounting. There’s a whole wide variety of components we make on the custom-molded polyurethane plastic side as well.”

Essentially, Weaver Industries embraces a well-diversified portfolio. “We naturally have that with the industries that we serve,” says Weaver. “There are constantly new industries being developed that use components we make, whether out of graphite as an advanced material, or out of urethane. Those are the positive things that have helped us span 70 years.”

Challenges, of course, have included the pandemic, a worldwide issue that affected Weaver Industries in myriad ways. “It changed the game totally,” Weaver says, from dealing with new regulations to justifying the ability to stay in business, to developing protocols and maintaining a sustainable employee base.

That quest also led into the ongoing challenge of enticing younger employees into the industry. “We need to get young people engaged in the trade so they can learn and become the next generation of employees who will be here for hopefully 30, 40, or 50 years,” Weaver says. “If you learn to be a machinist and can make something, you will always have the ability to make something.”

“It’s just harder to achieve that these days,” adds Manbeck. “It’s very difficult. Over the last two years, we’ve added three new machines, so Jim and Jason are continually investing in the business, and we had to try to maintain managing the downtime for one and then training on those pieces of equipment. While implementing these pieces of equipment, we’re also trying to maintain our current workload and customer base.”

As for milestones, an important one is automation. “A defining characteristic of a machine shop is having a high variability of parts and lower run volumes than an assembly line, where it’s easy to automate,” says Weaver. “We’ve been working diligently to identify those areas where it’s beneficial to optimize opportunities for automation and bring those in to reduce some of the reliance on that skilled labor.”

That’s not about eliminating people, he adds, but about maximizing productivity of those individuals and assisting them accordingly. “Being able to automate and run ‘lights out’ is a huge factor, which is what we’re focusing on while developing the next generation of employees.”

The company is also striving to drive profitability and growth through continuous improvement and cost reduction by achieving a return on the investments it has made in its people, equipment, infrastructure, and material inventories. “We have a lot of ingenuity and people who can think through problems,” Weaver says. “Problem solving is an important aspect of any job shop. We also do a wide range in size of work, making the smallest pieces demanded by the industry and also machining the largest monolithic pieces cemented together. We basically cover the spectrum from small to very large, and being a small, family-owned business, we take advantage of our ability to be innovative, dynamic, and agile in responding to what the market needs as well as what our customers need.”

“We’re unique in our marketplace,” Manbeck agrees. “A lot of our competitors are geared toward items smaller or larger in size, but we tend to run the gamut as far as size range and weight of parts.”

Being independent and family-owned provides Weaver Industries with the opportunity to source materials from all vendors who are producers of material, says Weaver. “If a company makes their own material, they’re going to provide that material to the marketplace. They’re not going to be able to necessarily source all the other materials made by other vendors.” Weaver Industries can, however, making it a true one-stop shop for the customer.

“We can find what works best and give customers that selection and opportunity to select the material they want,” Weaver says. “The whole goal is to allow us to generate revenues, efficiencies, and new opportunities that can continue to provide us the opportunity to be in business for another 70 years.”