This past November, AmeriGlobe, headquartered in Lafayette, Louisiana, announced that its revolutionary patented product, the Fusion Bulk Bag, the first practical and safe non-sewn bulk bag ever manufactured, and an industry game changer, was ready to hit the market.

The computer quality-controlled, thermally-fused polypropylene bags, which don’t require liners, are food-grade safe. This is because they are not sewn, and therefore have a zero percent chance of thread contamination. And because they are 30 percent lighter in weight, shipping costs are reduced.

Because of this ground-breaking—and award-winning, with AmeriGlobe, in cooperation with Dow Chemical, receiving the R & D 100 award for the Fusion Bulk Bag—innovation, the company itself is going through a transformation as it transitions from what was essentially a cut-and-sew operation to a high-tech company manufacturing the machines to produce the seamless fusion bags, the product other sewn bulk-bag manufacturers said couldn’t be made.

How it happened

To find out what all the excitement is about, we speak to company President Daniel Schnaars, Sr., and his son, Daniel (Dan) Schnaars, Jr., Vice President. “We’re still pinching ourselves from time to time that we got here,” says Schnaars, Sr.

“We kept it secret for a long time because if you asked anyone in the industry if you could put polypropylene together using heat they would have told you no. I think of the Roger Bannister story. He broke the four-minute mile in 1954, and until then, scientists said the human body couldn’t do it, but now thousands of people have. So we didn’t want the word to get out that there was a way to bond polypropylene. We wanted everyone to keep thinking it was impossible until we were ready to market it.”

He takes us back to 1980 when he began working in the bulk bag industry, and to 1985, when an investor from Houston, Texas had faith in his small start-up and his big ideas. Naming it FlexCon (Flexible Container) Systems at first, he began with a pickup truck and the idea of improving the functionality of bulk bags and by extension, the ability industry to transport products efficiently.

At the time, the industry was still new, having started up in the late ‘70s, with bulk bag manufacturers proving to clients that a five-pound plastic bag could hold 1000 pounds. “It was an alien concept,” Schnaars Sr. says, and while the sewn bags could do the job, they didn’t always do it well. Improving the efficiency and handling of the bags became a lifelong passion of his.

Over the years, FlexCon Systems, now AmeriGlobe, using industry-standard woven polypropylene, an inert material that doesn’t interact with its contents, developed more than thirty patented processes.

Patent success

“In the first two years, we came up with two important patents,” Schnaars Sr. explains. “One was to reshape the top of the bag to be conical, so you could overfill the bag and allow the corners to fill in. Otherwise, the one-cubic yard bags had eight to twelve inches of empty space, no matter how carefully you filled them. But by following mother nature’s rules and the laws of gravity, you could pack in another 26 percent of volume, because this was a flexible bag,” he shares.

“The second patent involved a method of attaching a polypropylene liner to the inside, because the sewing operation creates a lot of issues for the end users, including puckering and needle holes which can result in the product sifting out and allowing moisture and other contaminants to enter,” he explains.

“To overcome those problems, liner bags were introduced, but other companies just put them in loose, creating problems for end users who’d have to deal with seven-foot liners slipping out of the bag and into the equipment that was receiving the product.”

Even with these and subsequent patents that greatly improved the products, all was not smooth sailing in the early years. On two occasions in the first five years, Schnaars Sr. was within hours of announcing layoffs when a sizeable order came in, seemingly out of the blue.

“We never did lay off staff, and I think it was too coincidental not to have been divine help,” he says. “Moreover, we’ve had a lot of insights into product development over the years, and I think the good Lord is looking after us.”

To date, AmeriGlobe has been supplying standard bulk-bag styles, such as U-Panel, circular, and baffle bags, but with the added value of continual innovation. For example, some companies prefer baffle bags to get extra stability, and for them, AmeriGlobe has developed the MegaBase® which has the same stability without the 30 percent cost increase of making a traditional baffle bag with expensive internal baffling. It’s also easier to fill, reducing product sifting and contamination.

Meanwhile, The FreePac ™ with integrated BagPal technology eliminates the need for wooden pallets for shipping and the patented drop-down portion increases its overall stability when stacked, making it more efficient for both shipping and storage.

Although AmeriGlobe didn’t manufacture bags for liquid products in the early days, it has developed a patent-pending FreeStanding Drum Bag that provides the same stability for liquid as a heavier, expensive drum, but at less than two pounds of weight reduces freight costs.

Stateside or offshore?

Schnaars Sr. says that as far as he knows, “we were the only major company that didn’t move production to Mexico in 1995 when NAFTA was signed, and we stayed competitive against the Mexican companies.”

But after the Free Trade Agreement was signed in 2002 and much of American manufacturing moved offshore, primarily to India and China, Schnaars Sr. realized he had to do the same, because of the extraordinary difference in the cost of labor.

“However, we had customers who wanted their bags manufactured in the U.S., and that kept our U.S. factory alive. Those manufacturers consider the higher price they pay for the bags an insurance policy. If there are transportation issues—a dock strike, border closures, a pandemic—they’ll still get their bags.”

Adds Schnaars Jr., “This is an advantage our competitors don’t have. We’re fully in tune with problems our overseas contract plants might have, and when they need help in finding a better way, we can walk into the production plant here where our team’s working, and use a video camera to demonstrate the best way to do it.”

But no matter how innovative the approaches and how excellent the workmanship, the bags which AmeriGlobe produced had one thing in common with all other bulk bags, they were cut-and-sew bags, with their inherent problems. While the work is considered unskilled, Schnaars Jr. says it is in fact highly skilled, time-consuming, and needs intensive training to avoid the potential problems in sewing 1,100 stitches per bag.

Bonding with polypropylene

The solution to these problems is obvious—a non-sewn, fused bag—but it’s something that’s easy to propose and much harder to execute. The notion of a heat-fused bulk bag was not new and many other manufacturers had attempted it but failed. Polypropylene is so inert that there is no good way to bond it, and when they did manage it, they achieved a bond that was only about 10 percent of the strength of the original woven fabric, so no go.

But sometimes the best ideas do come out of the blue. Schnaars Sr. recalls how in 2013 a brilliant engineer they’d hired to build flood mitigation products using polyethylene, began experimenting with ways of strengthening and bonding it, which the company took to the scientists at Dow Chemical.

He describes how a scientist there looked at what the engineer had been doing with the polyethylene, and went quiet, apparently lost in his thoughts. “Then he said, ‘Give me three months, and we’ll do that same thing with polypropylene.’ Three months later, Dow sent us the materials and we tested them. The very first test was successful and that was the birth of fusion in 2014. A whole series of further tests told us it was achievable and feasible.”

These tests are stringent, requiring a performance ratio of five to one from the materials, ensuring, for example, that a bag designed to hold 1,000 pounds can be safely overloaded to hold 5,000 pounds.

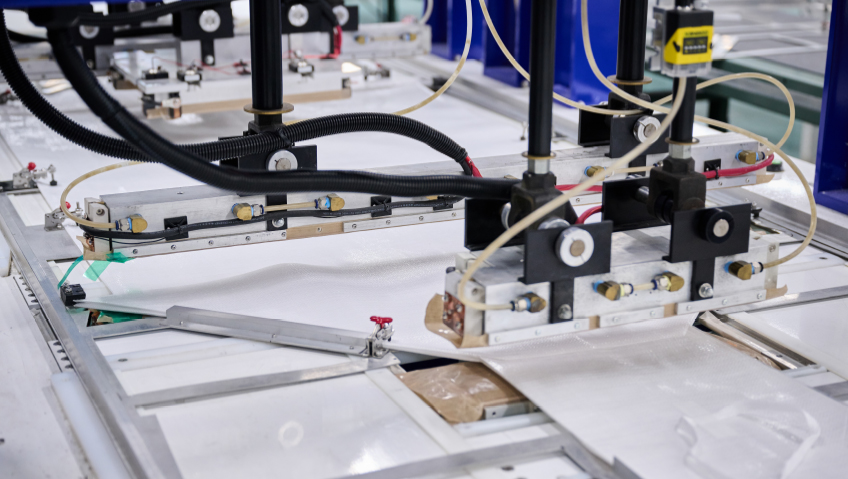

And then the company had to solve another series of problems when it set up the first production line in the U.S., an entire 7,500 square-foot room (which has since been modified to be more compact). “The entire process was long, complicated, and expensive, and if someone had told me it was going to cost close to $10 million, I probably wouldn’t have done it,” he says.

“To put that into perspective,” adds Schnaars Jr., we were a company with less than $20 million gross then and gave up all our profits over the last nine years to do this project.”

Since early 2022, the Lafayette plant has been in transition from a cut-and-sew operation to a machine-manufacturing plant where the complex machines with over 1,000 parts are being manufactured for their licensees in four or possibly five countries, including India, China, Brazil, and Mexico.

“We are getting out the word carefully because we don’t want to be overrun with orders we can’t fill,” said Schnaars Sr., noting that two of those lines for one licensee were operational when we spoke in November and that a third one had just joined them on-site where a new building was accommodating the machines. Another line for a second licensee began production on December 1, while equipment for a third licensee is scheduled for May of 2023.

The benefits of fusion

While the development process was long, arduous, and expensive, there are a multitude of benefits to manufacturers of the bags as well as end users.

For example, the process is much quicker and easier. Workers can make the bags in six minutes by folding the woven fabric and sliding it into the heating equipment as opposed to spending more than 20 minutes stitching one bag.

Manufacturers, from bulk food producers to chemical or fertilizer producers, can be confident there is no contamination and no danger of sifting. Shipping costs are less because these new fusion bags weigh 30 percent less than sewn bags. In addition, recyclable bags benefit the environment because the seamless fusion process eliminates the need for liner bags. “Using less of anything is good for the environment,” adds Schnaars Jr.

A big future

Schnaars Jr. believes that in the coming years, AmeriGlobe will be positioned to take over 35 percent of the industry. Currently, the equipment to manufacture one-bag style is on the market, but the goal is to design equipment that will produce all the company’s designs, including the MegaBase®, which poses some difficulty for automation because of its square base.

Still, he’s confident it will be done. “We are David, and we are hiring Goliath to work for us,” he says, referring to the company’s team of engineers. With the new manufacturing facility up and running to produce the equipment, AmeriGlobe will be able to give out more offshore licenses in 2025, but will also continue to manufacture bags in the U.S. “It’s important to us to keep a hand in our products.”