K-1 Technologies, based in St. Petersburg, Florida, has a supplier and customer base that spans the globe. The company is a distributor of electrical and electronic supplies and components—power supplies, semiconductors, wires and cables, connectors, and more—to a wide range of industries.

The products the company sells are often used in mission-critical applications, like aerospace and medical products manufacturing. Building trust with customers is just as critical, and that means ensuring that components are exactly what they’re supposed to be. This is one reason the company is embarking on what Bruce Tharpe, K-1’s Manager of Strategic Allotments & Cost Analysis, calls an exciting new journey.

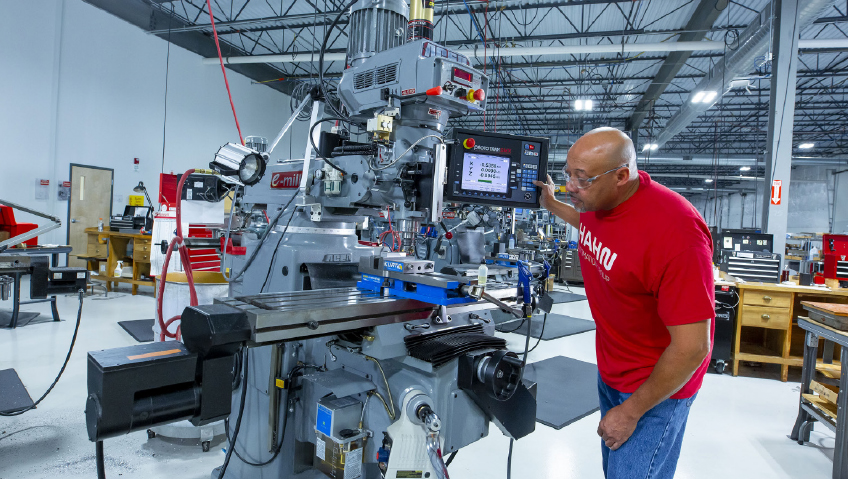

The company is highly accredited. It is AS9120 and AC0056 certified—both for its work in aerospace and defense—and also possesses ISO 9001 quality management certification. K-1 Technologies is now pursuing certification for all three levels of AS6081. With the support and assistance of its partner, Global Electronic Testing Services, K-1 has installed the equipment and accessed training for its staff that AS6081 certification will require.

According to NQA (National Quality Assurance), the body that provides the certification, the AS6081 standard was created due to a significant and increasing volume of counterfeit electronic parts found in the aerospace supply chain. The safety risk posed by these fraudulent parts is clearly unacceptable in these kinds of applications.

“You have to have those safeguards in place,” Tharpe says. “We have a responsibility to our customers to safeguard their reputation and their warranties. We’re putting up an even stronger defensive front to make sure they don’t receive substandard parts.”

For K-1 Technologies, the first level of protection is careful management of its supplier relationships. “We have 15-year relationships with some of our suppliers,” Tharpe says. “We know and trust them. A new supplier really has to prove themselves over time.”

Along with supplier management and product inspection, he says, AS6081 testing will complete the company’s three-prong strategy to protect its customers against the risks of faulty components.

In the past, K-1 Technologies has outsourced this level of testing when it’s been required. Going forward, the capability to do it in-house will mean consistently faster turnaround times for customers. And it’s not just about delivery timelines; according to Tharpe, the company plans to ultimately provide a minimum Level A testing under the AS6081 standard by default on every component it sells.

It’s all about building a high level of trust with customers. K-1 Technologies offers a 10-year warranty on its products, and this change means backing that warranty up with the confidence of extensive testing.

“We don’t have the luxury to make mistakes that could affect our reputation,” Tharpe explains. “Larger entities have more security because companies have to purchase from them; they can make mistakes. If we make a mistake, we could lose a customer forever. Our service has to be at a higher level to retain customers and continue to grow.”

Building relationships with customers as a trusted partner is nothing new for K-1 Technologies. In fact, it’s embedded in the operating philosophy of the company, and has been since day one.

The company was founded in 1995 by David Razawi. Razawi was working with a company that—like K-1 does today—provided support with distribution. Tharpe, who worked with Razawi at the time, remembers him saying that he thought the business could do better than a ‘one-size-fits-all’ approach. “He’d say, ‘This can be done better. This can be done more efficiently, and more with the customer’s unique needs in mind.’”

With that end in mind, Razawi launched the business, and it’s been growing ever since. “The business was founded on the philosophy of building relationships,” Tharpe says. “Being closer with customers—not growing so large that everything becomes automated and you lose that personal touch.”

The company’s CEO, Michelle Gorman, sees that philosophy embodied in the company’s operations to this day. “We learned early on that great OEMs and CMs (Original Equipment Manufacturers and Contract Manufacturers) not only produce top products and excellent manufacturing,” Gorman says, “but the supply chain is supported by creative and flexible partners willing to do more and take on more responsibility. That’s the main reason we go above and beyond what our customers expect, even in an industry where extreme challenges, countless competitors, and fluctuations in demand are commonplace.”

The flexibility, and the personalized approach, pays off when it comes to attracting customers. “A significant number of our new customers come to us when they run into a roadblock with another supplier,” Tharpe says. “When there’s something another supplier couldn’t or wouldn’t do, we’re able to help them.”

For K-1 Technologies, this is what it means to be a true partner. It’s evident in the way the company responds to unforeseen events to support its customers.

When the pandemic first hit, the company’s leadership knew that their customers were at risk of supply chain disruption. The team immediately began using business data to predict what the impacts were going to be, and how best to mitigate them.

“We saw it coming,” Gorman says. “We knew this was going to create significant supply problems for our customers. Many manufacturers were shut down for several months, and that was on top of existing shortages. The pandemic compounded a situation that was already challenging.”

Although the impact of the pandemic on business was unprecedented, K-1 was able to anticipate and respond to the challenge because it had supported its customers through previous interruptions over its nearly 28 years in business.

“There was the analog to digital shortage in the late 1990s. There was a severe capacitor shortage, with the boom in cell phones, when demand for tantalum outstripped the supply,” recalls Tharpe. “More recently, there’s been an MLCC (multilayer ceramic capacitor) shortage.”

Sales Manager Dan Duffy agrees. “After years in the industry I learned many times how I could make a difference in our customers’ supply chains,” he says. “K-1 can do things other suppliers can’t or simply won’t do, saving them money and headaches in the process.”

Anticipating what was on the horizon, K-1 tapped into its global network of suppliers to identify alternate sources of components and other products. Moreover, throughout the worst of the supply chain challenges, the company kept prices as reasonable as possible, narrowing its own margins to help customers control their costs. Notably, the company did this at a time when some others were taking advantage of shortages to increase their margins.

Now, K-1 Technologies is helping its customers again with the flip side of that equation. Prices have dropped, and K-1 is making sure its customers know so that they can take advantage of the savings. In some cases, Tharpe says, those savings can reach into the seven-figure range.

This is another example illustrating how K-1 Technologies goes above and beyond. The company has the capacity to offer VMI (vendor managed inventory) service to its customers. K-1 purchases the components and stocks them, delivering them at the moment they’re required by customers. For those customers, keeping these components off the shelves—and the balance sheet—adds up to significant cost savings.

Unlike some of its competitors, K-1 Technologies offers the additional security of guaranteeing the price of those components through the life of the order. This gives customers a greater level of predictability when budgeting and forecasting. “Even a small price variance can add up very quickly,” Tharpe says. “Multiply that variance by hundreds of different line items, and it can become a logistical and financial nightmare.”

Given the compounding effect of price variances on large numbers of components, K-1 Technologies is always looking for innovative ways to reduce costs for its customers.

“We’ve picked up manufacturers and brands that are less known in the United States,” says Tharpe. “They’re ‘white label’ companies; they make the products for everyone else. The products are exactly the same, but their costs are lower because everything is done in-house. It’s vertically integrated.”

Indeed, K-1 Technologies occupies a uniquely balanced position in a competitive market. The company is large enough to have the capacity to offer its customers a comprehensive line of products and advanced distribution capabilities, and still small enough to provide flexibility and a personal touch. And now, with its pursuit of AS6081 certification, K-1 Technologies is building on a quarter-century of relationships with suppliers and customers alike, taking trust to an even higher level.