To navigate the precise and demanding field of precision grinding, an experienced touch is often required. As a result of the need for manufacturers to meet tight specifications, it can be difficult for businesses to locate and acquire the machines that fit their specific needs. In Winona, Minnesota, DCM Tech is proving that machines that are good for grinding are good for business.

Located 120 miles (195 km) southeast of Minneapolis, the company’s stellar track record shows it’s able to provide precision grinding machines to meet virtually any need.

Founded in 1974 by entrepreneurs Dan Rukavina and Dave Arnold, DCM Tech began as a designer and manufacturer of specialized machine tools for the automotive aftermarket.

Enjoying early success in the auto aftermarket industry manufacturing various types of equipment, the company quickly gained a reputation for quality machine tools and customer satisfaction.

Over the following decades, DCM would expand to offer different models of flywheel grinders, belt resurfacers, seat and guide machines, head and block surfacers, and magnetic particle inspection machines. Constant product development like this still happens today and the company continues evolving its product line, while still maintaining close customer relationships.

Dave’s son Dan Arnold is now company president. He continues his father’s work of providing industry-leading precision grinding machinery.

As DCM has responded to changing market trends, specifically a decline in the automotive rebuilding industry, the company has transitioned into a line of rotary surface grinders that meet a wide variety of customer needs. This line boasts rotary tables from 12 to 48 inches (30 to 122 cm), and variable-speed grinding spindle motors from 5 to 50 horsepower.

Internal air mist collection and coolant flow systems ensure a clean and consistent grind with minimal disruption to the work environment. Digital handwheels allow custom Z-axis control, giving unprecedented accuracy, and an internal memory allows operators to save custom grind recipes, ensuring rapid switchovers when needed.

With ceramics grinding, DCM Tech’s machines are notably efficient and precise, encouraging shops to remain focused on more big-picture items while the machines handle the details. Arnold estimates that 30 percent of the company’s business is in aerospace and similar markets, which has resulted in extensive experience with grinding ceramics, glass and specialty materials.

The company’s machines provide a positioning resolution of 0.0001”, to better conform to the tight specifications required in industries like ceramics and glass manufacturing. Speed is also an asset: thanks to additional advances in abrasives and feedrates, DCM Tech’s machines have been shown to reduce or even eliminate the need for finishing processes such as polishing and lapping.

But beyond the outstanding abilities of DCM Tech’s machines, it is the company’s experienced engineering and customer service team that lifts it above its competition. “We provide a product we can optimize, with features and options that specifically meet the customers need and confirm it before we ship,” Arnold says.

Marketing Director Ashley Johnson contributes to this theme, remarking how many companies mass-produce machines designed for a single purpose. “We work directly with each and every customer based on their application, so the machine matches them, not the other way around,” she says.

DCM Tech operates a comprehensive approach to its sales, working with each customer to individually design, test and ship a machine custom-made to fit the customer’s unique specs. While the company doesn’t quite have everything it needs to manufacture everything at its shop – such as a foundry – thanks to its local focus it can easily source high-grade components from local suppliers. Of all machine work, 80 to 90 percent is performed in-house, greatly reducing lead times.

To personalize the sales process, a single DCM technical specialist works with clients each step of the way, forging a strong working relationship and answering every question a client might have. Clients see a familiar and friendly face as they navigate the critical task of machine selection. Each specialist works with the client through the sale, installing the machine, training their operators, and handling any service or maintenance questions for the life of the machine.

“That’s another benefit of being small and family-owned, and it sets DCM apart a lot,” Arnold remarks. As a part of this comprehensive relationship, DCM uses its existing machines to provide ground samples to clients, ensuring clients see the finished result before moving forward.

In addition to grinders, DCM Tech’s product line includes a wide range of added features and individualized components to accommodate truly precise jobs.

Abrasive grinding wheels are available from 3 to 48 inches in diameter (approximately 8 to 30 cm) in conventional materials, diamond or CBN.

Coolant units specially designed for DCM machines provide 25 to 50 gallons of coolant, with added filters to prevent even the finest of particles from entering. This circulation and filtration of the coolant aids in the consistency and repeatability of the grinding processes performed.

Finally, DCM carries an inventory of consumable supplies and replacement parts from machine lubricants to electrical components, ensuring clients have access to the necessary items to keep their machines running smoothly and minimize maintenance downtime.

Beyond DCM Tech’s product offerings, the company’s small size helps it focus on customer relationships, rather than a simple bottom-line profit. Arnold remarks how this ‘small-company’ feel helps its staff better interface with its customers. Additionally, it has decades of experience on its side.

“Many of our coworkers have been employed with DCM for over 25 years,” he says. “This allows us to have so much knowledge when helping our customers.” It’s not uncommon, he continues, for veteran employees to assist with unusual service calls – which rarely happens in larger companies.

As Arnold explains, a direct sales model helps DCM Tech understand the exact nature of its customers’ needs and encourages a symbiotic relationship. “Let’s understand your problem,” he says. “How can we improve it? What can we do in our machine design to better solve a specific customer’s problem? Every application we have, we learn something.”

Ashley Johnson notes that these customer relationships have decisively influenced ongoing machine design. “When we think about our future plans, they really are based on what we hear from our customers.”

The result is self-evident. DCM Tech works with OEMs across multiple sectors, including optics, aerospace, additive machining and defense. Capable of working with materials beyond ceramics including glass, steel, silicon carbide and more, the company’s products are more than capable of handling grinding and precision machining.

As an example of the machines’ efficiency, Arnold tells how a customer previously had fourteen reciprocating grinders, with seven operators, on their floor. “They purchased one of our machines, and then got rid of the other fourteen,” he chuckles. “It was a 14-times productivity improvement for that customer and that application.”

Right now, the company is squarely facing the fact that many of its most experienced are approaching retirement age. To address this potential issue, the company is working closely with local technical schools to help educate incoming students about manufacturing, and has four employees that are enrolled in a continuing education program centered on manufacturing.

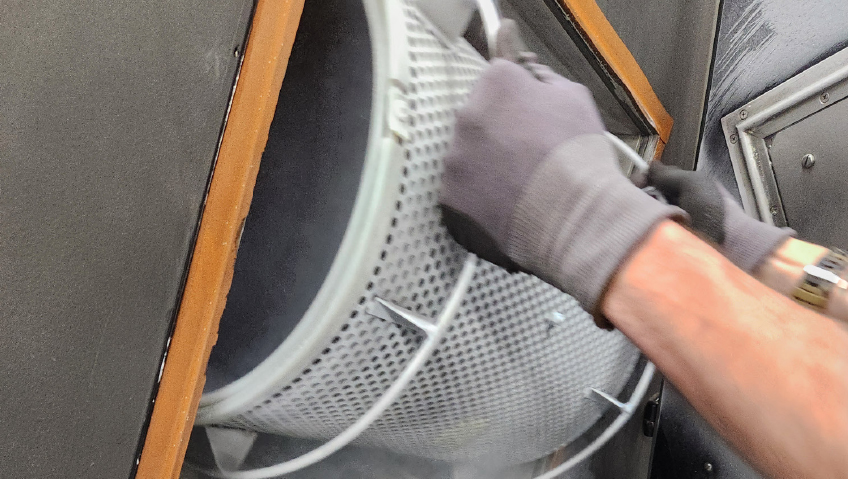

DCM Tech also works intensively with local colleges to showcase its operations to machining and engineering students. As an important part of this, the company is working to polish the image of its industry – the very word ‘grind’ conjuring images of grit and dust in a ‘dirty job.’ But thanks to the company’s fully enclosed machines, such stereotypes will be a thing of the past.

DCM Tech’s latest machines also require far less training than earlier models. Simple LCD touchscreen controls – a far cry from the many analog switches and dials of yesteryear – allow operators to understand how to use the machine in a matter of minutes. This, Johnson says, is key to the company’s future strategy to attract both new customers and new employees: “It’s really important to our customers today to have a machine that’s easier to understand and use,” she says.

This increasing focus on ease-of-use, coupled with advances in automation, will help drive the company forward – although Arnold is quick to dispel any notions of five- or ten-year plans. “We’re opportunity-driven,” he says.

But as the company maintains its focus on customer service, driven by its family-owned nature and “smaller business” agility, DCM Tech looks like it will continue producing machines that provide unique capabilities in a unique way for a long, long time to come.