The United States is well underway with its strategy to strengthen domestic manufacturing, but reaping the many economic advantages therein will not be possible without players like Center Street Technologies, where advanced design, state-of-the-art technologies, and innovative manufacturing platforms intersect.

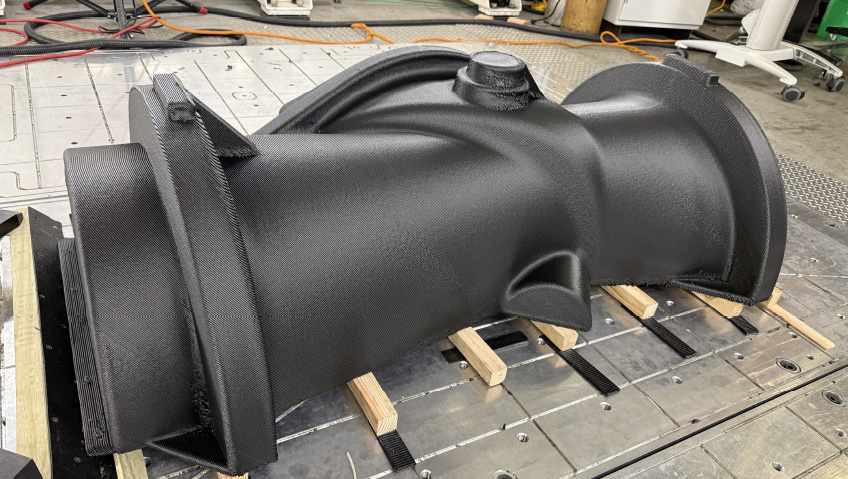

Center Street Technologies is a team of subject matter experts who have come together to demonstrate the capacity of additive manufacturing as a means to augment existing manufacturing processes by producing large-scale polymer-based structures and components.

Using advanced modeling and simulation paired with leading industrial controls and automation, and through an innovative approach to design, engineering, and materials sciences, the company’s comprehensive manufacturing solutions have served partners in aerospace, defense, and many other industries that recognize the added value of this approach.

Growing manufacturing capacity in a big way

It is an exciting time for Center Street Technologies. Having proven the performance of its equipment and the validity of its processes, the company has positioned itself as a beacon of opportunity for players across markets and sectors, particularly where there is demand for high-mix, low-volume parts, like the maritime industrial base and shipbuilding sector where supply issues not only threaten production, but also national security.

“A known issue right now is the ability to source castings needed for production in a timely manner. At Center Street, we’re able to rapidly create patterns that have been damaged in use or are obsolete and needed for sustainment with little to no existing digital engineering data,” explains Matthew Heffinger, the Product Engineering Manager at Center Street Technologies, of the company’s reverse engineering capabilities for large-scale components.

And they are large indeed. The company’s flagship machine, the AMC2304, is aptly named for its capacity. At 12’ x 24’ x 8’, it boasts 2,304 cubic feet of build volume. Equipped with a dual gantry system capable of high output large format additive manufacturing (LFAM) and five-axis machining, it serves as the company’s principal production platform.

Development projects start in the digital environment and are taken to the smaller AMC160. Again, named for its size and capacity at 4’ x 8’ x 5’, the AMC160 is equipped with the same three-axis extrusion system as the AMC2304 as well as a new six-axis articulating Comau industrial robot. Complete with Siemens industrial controls, it serves as the core development platform for Center Street.

“All of our systems run Siemens SINUMERIK ONE controls, which is their latest and greatest controller,” Heffinger says. This robust control system enables the design and production of highly accurate digital twins. “We’re able to digitally emulate the whole control system to prove out new controls and engineering-related developments prior to downloading them to the physical equipment. It’s a very accurate simulation of our control system as a whole,” which enables a more efficient and effective development lifecycle.

According to Process Engineering Manager, Casey Gonatas, the AMC160 “is a smaller volume machine with the same extruder where we can develop different components, tool pathing strategies, or perform any other kind of R&D activities we need to, without interrupting production on the AMC2304.”

Adding the six-axis robot to the AMC160 enables the integration of multiple advanced manufacturing technologies working together to produce parts. The addition of the robot enables the use of many end effectors to fulfill different tasks in a staged approach, such as pick and place operations, milling, inspection, and automated fiber placement (AFP).

“We’ve successfully machined parts using the robot with the machining spindle as the end effector. It has been an exciting development to be able to do the milling work in that cell as well, which is now more of a direct comparison to the AMC2304 that’s able to do the printing, machining, and inspection,” explains Gonatas.

The integration of Grale Technologies’ inspection application—considered a leader in commercial digital metrology functions that offer real-time measurement of parts without interruption—elevates the efficiency and accuracy of the AMC systems.

Greater capabilities, validated results

Over the last year or so, Center Street Technologies has worked diligently to expand its general production capabilities while continuing to identify ways to address gaps in manufacturing through advanced technologies and additive manufacturing.

For instance, its efforts in lightweighting are timely given the 2025 updates to the Corporate Average Fuel Economy (CAFE) Standards. Lightweighting, also referred to as foaming, is a process whereby the extrusion process is altered to offer a lighter overall weight without the need to adjust shapes or toolpaths. According to Heffinger, “Current lightweighting techniques in the 3D printing industry limit you to lower performance polymer materials, but we have developed methods to lightweight aerospace-grade, high-performance polymers,” which is gaining the attention of leading industry players.

Commercialization of new technologies and approaches is always a challenge, particularly as many customers are risk averse. It is hard to offer an outright guarantee that the applications and components will perform to expectations; however, over the last several years, Center Street Technologies has been collecting data to ensure the quality of its products. What the team found was that it was not always necessarily the cheapest option, but was faster, more efficient, and dedicated to optimized quality and throughput.

From a quality management standpoint, Center Street Technologies is on the verge of becoming AS9100D and ISO 9001 certified. Having received official recommendation for certification from its auditor, certification is expected in February 2026. The company is also working toward CMMC Level 2 compliance, which will further improve its credibility within critical industries like aerospace and government entities.

“As we spend time addressing government-related issues and developing technologies to solve complex problems, it gives us the ability to mature our technology and provide a more viable product to the commercial markets,” Heffinger explains. Where time is money, this is invaluable.

The application is especially useful for prototyping as it requires less rework or subtractive manufacturing to achieve quality results. During the design phase, the team can adapt quickly and make necessary adjustments through digital engineering capabilities before going to print, controlling quality throughout the entire process.

Scaling success

The team at Center Street Technologies is a small, tight-knit group that leverages its two machines to address issues that traditional manufacturing cannot, particularly where high-mix, low-volume components are concerned.

As Gonatas notes, “We have the two machines for producing parts, so that’s our main constraint internally as far as scaling up to a higher production rate. But the nice thing about how strong our digital backbone is, is that everything can be easily scaled to fit different machines, platforms, and customer requirements,” which highlights the flexibility of the process.

Through its work, Center Street Technologies is striving to build confidence not only in advanced manufacturing applications like additive manufacturing, but in the sector as a whole through strategic partnerships dedicated to workforce development. With its partners, the company serves as a conduit between academics and industry to seek out ways to strengthen the advanced manufacturing workforce through development programs and initiatives to ensure that there is a pipeline of talent at the ready to scale with demand.

“There’s a lot of development within academia that is never implemented within the manufacturing industry. We want to interface with research labs and academia to transition the technology and make it reachable to the broader manufacturing industrial base,” Heffinger explains. At a time when the U.S. is losing legacy manufacturing operations and struggling to find a skilled workforce capable of fulfilling growing demand, these efforts are not only appropriate, but valuable.

As Gonatas tells us, “There are less and less people trained in traditional manufacturing roles, so being able to attack it with more of a digitally focused approach—something with more quality control and engineering going into the work—is something that we can bring to the table and have a positive impact on an industry that’s hurting right now.”

Advancing the industry

From workforce development to advanced manufacturing applications, Center Street Technologies continues to identify the best use cases to demonstrate the value of its approach and the impact its technology can have on American manufacturing. Additive manufacturing and advanced manufacturing approaches will be key to unlocking the true potential of the U.S. manufacturing sector and economy, and those who recognize this value are poised to thrive.

The focus moving forward will be “getting people in the industry or potential customers to see the value and think of additive manufacturing or advanced manufacturing as more of a realistic solution, not just as a last resort or a cool niche,” explains Gonatas, who notes that at Center Street Technologies, “we’re making real products that are fully capable of meeting a customer requirement.”

The goal is to get operations to take that leap of faith, to look beyond traditional manufacturing processes to unlock the value of additive parts and components. Such parts are proven, validated, and capable—now they just need to be fully leveraged for their value to be truly realized.