Since 1972, Samco Machinery has been a leading manufacturer of roll forming equipment serving the automotive, building and construction, racking and shelving, transportation, energy, and consumer goods industries. Over the decades, Samco has evolved into a complete turnkey solutions provider, offering a comprehensive range of machinery and services, including uncoilers, coil cars, flatteners, roll form dies, roll formers, presses, and material handling systems.

An ISO 9001-certified company, Samco proudly serves clients in more than 35 countries, combining deep industry expertise with a commitment to engineering precision and innovation. Every solution is custom-designed and engineered-to-order, ensuring that each customer’s unique production requirements are met with efficiency, quality, and reliability.

Vertically integrated: empowering customers through flexibility

While Samco was originally established to meet the market demand for roll forming machinery, helping customers achieve speed, precision, and high-volume production, the company has since evolved to meet a broader range of manufacturing needs.

Through its Rolling and Fabrication Divisions, Samco now supports organizations whose requirements may be smaller in scale, i.e. companies without high production volumes, with limited floor space or startup capital, or those whose business models are better suited to contract manufacturing rather than equipment ownership.

“I’ve been with Samco 11 years, and my job was to look for those opportunities and seek out organizations that required that type of service,” explains Darryl Levesque, Vice President – Rolling & Fabrication Division.

Samco’s deep focus on customer-centricity led to the creation of its Custom Roll Forming Division, designed specifically to serve clients who needed manufacturing services rather than full-scale roll forming machinery.

“That’s where the Rolling and Fabrication Divisions came in, to satisfy those customers who didn’t need a roll forming line; they simply needed a roll formed or fabricated product,” says Darryl. “Many of these companies weren’t interested in producing in-house. They were looking for a contract manufacturing partner who could do the work for them.”

By leveraging its expertise and advanced production capabilities, Samco helps clients save both time and capital, producing the volume they need without requiring investment in machinery or specialized labor.

“We sought out these opportunities, grew the business, and found customers that really needed that type of service,” Darryl adds. “Whether it’s prototype parts or small production runs, our vertical integration gives customers the ability to start small—and dream big.”

Rolling out the Rolling Division: extending Samco’s customer commitment

Samco’s Rolling Division represents the same dedication to excellence that has defined the company since its founding, a relentless drive for execution, delivery, and customer satisfaction.

Relationships at Samco are built on trust, expertise, and shared success. The company’s collaborative approach begins with active listening, which fosters open dialogue, sparks innovation, and leads to process improvements, shorter lead times, and reduced costs.

“The customer is everything,” Darryl stresses. “You’ve got to put yourself in their shoes. They’re not familiar with the roll forming process or the technology, so through our ability and knowledge of what can and can’t be done, we are able to confidently educate them about what we are, and ultimately, what they are capable of achieving.”

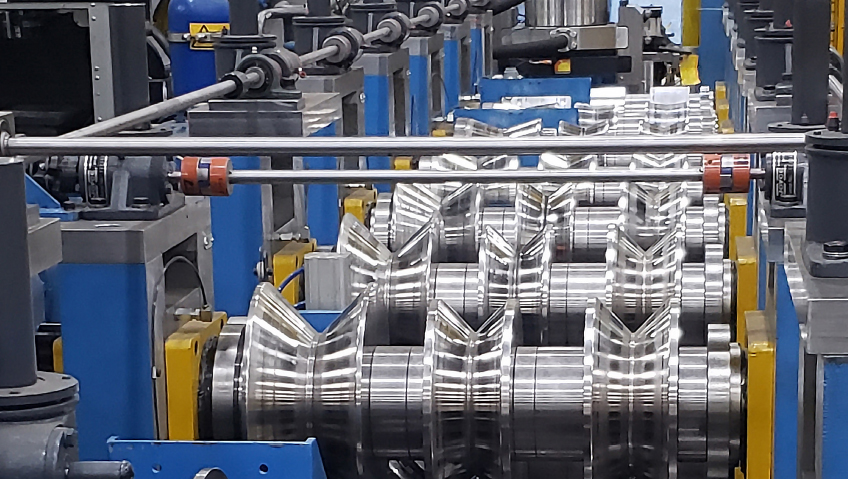

From concept to completion, each project is guided by Samco’s commitment to precision and efficiency. Depending on the complexity, the journey from development to tooling can be extensive, but Samco’s in-house design and tooling teams streamline this process from start to finish.

“That’s one of the benefits we have with design staff in-house,” Darryl explains. “We design our own roll tooling in a way that meets our standards and, at the end of the day, produces the product the customer is looking for.”

Furthering fabrication: completing the vertical integration

Five years ago, Samco identified both a need and an opportunity to expand beyond roll forming and become a fully vertically integrated manufacturer. The company responded by investing heavily in new equipment, advanced capabilities, industry certifications, and deeper engineering expertise.

“There are a lot of other fabrication shops and competitors out there,” notes Darryl, “but what we offer is the engineering knowledge and backing, the right equipment, and the understanding of where the customer wants to take their business.”

Today, Samco offers a comprehensive suite of fabrication services including laser cutting, brake pressing, shearing, bending, robotic welding, and certified structural welding. This end-to-end capability provides customers with economies of scale and the convenience of a one-stop shop.

“The one-stop shop mentality works in leaps and bounds,” says Darryl. “Not only do we have the core competency to offer all those processes, but we’re already pre-qualified in terms of quality.”

Samco’s ISO certifications further reinforce its dedication to quality. “We take them very seriously,” Darryl emphasizes. “We have extremely high standards and requirements in-house.” Each Samco division is individually ISO certified, giving customers the added benefit of time, cost, and efficiency savings.

Building relationships: the core of Samco’s success

At the heart of Samco’s continued success is a commitment to people, both customers and employees. The company’s focus on building strong, lasting relationships has been central to its growth for more than five decades.

“The machinery side is incredible, one of the first things that drew me to this company,” says Darryl. “Building the Rolling Division was really an extension of our pride in what we’ve accomplished on the machinery side, knowing that our machines have been in the field for 40-plus years and that our customers trust us for quality.”

That same innovative spirit drives Samco’s engineering team, a “fantastic crew,” as Darryl describes them, who are developing proprietary software and programs that anticipate and integrate AI-driven process advancements.

“There’s an expectation from the marketplace that if AI exists, it should make a client’s process easier and we’re addressing that,” says Darryl. “We’re constantly investing in R&D and reinvesting in resources—not just equipment, but knowledge to help our customers be more successful and efficient.”

For Samco, the formula for long-term success is simple: listen, innovate, and deliver.

“It’s about clients knowing they can count on us,” Darryl concludes. “Knowing that Samco will deliver and go to the ends of the Earth to meet their needs.”