Offering precise automated machine tooling systems to the global manufacturing community—and in particular, engineering custom solutions for some of the most difficult manufacturing applications—Bourn & Koch, LLC specializes in precision grinding machines and gear manufacturing equipment.

Bourn & Koch provides field service, rebuilding, retrofitting, and repair parts for 29 American machine tool companies. Boasting archives representing more than 2,500 years of engineering expertise, the company brings unique solutions to the modern manufacturing sector while preserving the still-useful machinery that gave rise to American industry.

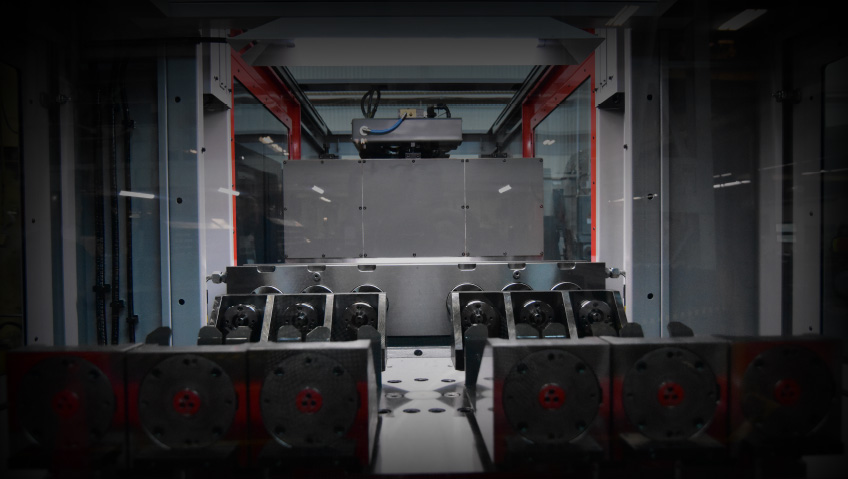

Founded in 1975 in Rockford, Illinois by engineers Larry Bourn and Loyd Koch of Sundstrand Machine Tool, Bourn & Koch has since made numerous changes and upgrades to its lines, from redesigning and re-engineering the Blanchard 22AD-42 rotary surface grinder, bringing it up to date with the latest technologies, to developing gear hobbing and shaping technology ranging from 25 to 1280 millimeters of work envelope. More recent engineering developments include the new MT3 (pronounced M-T cubed) vertical grinder, which combines milling, turning, and vertical grinding into a single machine platform.

Opportunity is where you find it

Other changes are also underway for this innovative company. In 2023, InCompass acquired Bourn & Koch and Mollart as part of two separate acquisitions. As a result, Bourn & Koch took over Mollart’s operations, sales, and field service support, previously based in Chessington, United Kingdom.

Mollart, which creates and produces equipment for deep hole drilling, multi-spindle pellet die drilling, micro-drilling, BTA deep-hole drilling, and gun drilling, began the process of moving production to Bourn & Koch’s Rockford facility in early 2024. “InCompass is a group of machine tool companies with some familiar names in manufacturing like Clausing, Bridgeport, and Timesavers, so it’s a great home for us,” says Joe Goral, Vice President of Sales. “We’ve made a number of improvements in our 130,000-square-foot facility to welcome Mollart’s product line and now build those machines here,” he tells us.

Improvements also included purging some aged inventory and leveraging ‘5S’ to make space for the growth and fit of everything from the London operation, adds Vice President of Operations Todd Wells. “We also reconfigured the factory layout to allow building of larger gun drilling machines into a high bay we already had.”

Along with relocating the assembly and service parts warehouse from the London facility to the Rockford factory, Bourn & Koch added some critical roles to support the integration. The company has also leveraged the workforce development programs available at IMA (Illinois Manufacturers’ Association) and TWC (The Workforce Connection), Rockford’s local workforce board, to support the delivery of critical education to its workforce. IMA and TWC support investments in developing critical skills, such as skills for machine building and CNC machining, the gun drilling application being a new CNC application to the BK team.

Building skills

“Gun drilling has been quite a learning curve for us,” Goral shares. “It’s not something we’ve done previously, but we’ve learned it, supported by Mollart employees from the UK who we’ve retained to continue production of these machines.”

With all the unknowns that preceded the acquisition and move, this success has come as great news, he adds. “When you build a machine for the first time—something we do a lot because we’re involved in special machine tool manufacturing and custom engineering—there are a lot of times where the machine just doesn’t exist before we build it.”

This means there’s always some risk involved. Bourn & Koch visited the Mollart facility in the UK, did their homework, and were “cautiously optimistic” that things would go well. “It’s great to hear one of their longtime employees come here and compliment the job we did. We really enjoy hearing that, and it bodes well for the future success of having this work here.”

Mollart’s business is roughly 50 percent North American and 50 percent global, with a prominent presence in Canada, the U.S., and Mexico across major sectors such as medical, automotive, and firearms. “Being on the sales side of things, I get to visit customers in the factory and see how these machines are integrated with their processes,” says Goral. “I’ve seen some very impressive fully automated lines where transmission shafts are moved through the factory to the gun drill, and then on to other processes. It’s really neat to see the success they’ve had in the past with these customers, and to be able to continue that.”

A new start for Blanchard

As for the Blanchard product line—a company brand since 2004—for the first 14 years after the acquisition, Bourn & Koch built the machines in the Blanchard way, updating the controls and systems as they went obsolete, but still based on their original engineering. However, in 2018 Bourn & Koch redesigned the entire machine and process, adding numerous features that certain segments of the market found valuable, including a full, automated stainless-steel enclosure with a roll-up door and power dresser. The company is now making an effort to redesign it again to better meet what the majority of the market is looking for in a rotary surface grinding machine.

“That doesn’t mean we’re going to abandon the current design of the machine,” says Goral, “but just simplify it to make it fit what the market wants and bring it to a price point that’s easier to justify for smaller manufacturers and companies that may not need the technology level of the current design.”

This means simplifying the controls and reducing the footprint so the machine does what a Blanchard needs to do but isn’t over-engineered for the application. The company is gathering market feedback and spending a lot of time with its customer base before getting to the prototype phase to ensure it ticks all the boxes.

“While Joe is out there getting customer input directly from the user base, our internal team is submitting ideas about what changes would make the product easier to manufacture and assemble,” Wells adds.

Learning and leadership

To maintain its quality of workmanship and grow a skilled workforce, Bourn & Koch has continued to develop its learning management system over the past eight years. While experiencing some false starts with other programs, it eventually joined the Rock River Valley Tooling and Machining Association (RRVTMA) to design an apprenticeship program that fits the demands of developing relevant skilled labor.

As the local branch of the National Tooling and Machining Association, the RRVTMA has a key partnership with Rock Valley College, the local community college, which Wells says is a big part of its success in the area. “It marries well with our learning management systems so we can upskill,” he says. “We service, design, and build a variety of CNC machine tools—grinding, hobbing, shaping, milling, drilling, and turning.”

The RRVTMA makes a good fit with Bourn & Koch, allowing machine tool builders to undertake an apprenticeship program that supports skills and growth. “For the first time in 2025, we’ve successfully leveraged the program all the way through to having two graduates,” says Wells. “We’ve taken two apprentices through that four-year program for them to achieve their journeyman credentials. That’s a big win for us this year.”

Constructing CNC machines involves the integration of complex electronics to bring motion to an otherwise mechanical system. Bourn & Koch leverages the mechatronics program at Rock Valley College’s Advanced Technical Center to speed the development of electro-mechanical skills necessary to build these machines. “RVC has invited us to the table to help align their program with our needs,” Wells says. “This program helped deliver the skills necessary to grow the volume of panels built and controls integrated within the factory.”

The company has also partnered with the State of Illinois through a grant program which marries well with the training program. “Leadership skills are among the skills that have been hard to get,” says Wells. “We’ve used these tenets and job principles to guide us through a project for the past year and a half, working with our local workforce board so we can identify the marketable skills in every single business segment here—whether it’s sales or operations or the finance team—to clarify what the career pathways are for our entire business.”

This means that all employees at Bourn & Koch, regardless of their role, understand the steppingstones of their career. Through this project, the company has developed a 23-lesson leadership program that helps managers understand how to succeed in their position.

“It’s one thing to promote somebody to manager; it’s another thing to show them how to do it,” says Wells. “We’ve spent a lot of time over the past year helping our managers know how to be good managers—how to understand employment law, our internal processes for performance reviews, and the training program itself.” This has included increasing the flexibility of work schedules to support work-life balance, which is much appreciated. Employees surveyed in connection with this project are 94 percent satisfied with career opportunities at Bourn & Koch.

From a national system standpoint, the National Manufacturing Extension Partnership (MEP) program has also been vital, offering an excellent leadership program developed to help qualify leaders, along with the local chapter, IMEC (Illinois Manufacturing Excellence Center), Illinois’ MEP, and the IMEC Leadership Development Program.

Facing down challenges

Unfortunately, recent budget cuts throughout the U.S. may lead to MEP programs being cut, putting those invaluable opportunities, particularly for a smaller manufacturer like Bourn & Koch, in jeopardy.

“That immense value we get through IMEC and the immense value that other manufacturers get through these MEPs may no longer be an option,” says Goral. “Grant funding supports a lot of these programs we’re talking about, and it’s helpful when we look at how we justify and pay for them.”

IMEC has also been an invaluable resource across the organization. Without that grant funding, companies won’t have those opportunities. “I’m glad Joe said it; I agree with it,” says Wells. “It’s a very important program, and we’ve been fortunate so far to be able to be supported by those entities. I hope that continues.”

Despite uncertainty surrounding future funding, Bourn & Koch’s history of innovation, adaptability, and investment in its people suggests a strong path forward. By blending time-tested machine tool expertise with forward-thinking engineering, the company continues to equip manufacturers with the tools, skills, and leadership they need to succeed. A dedicated workforce, loyal customer base, and proven ability to turn challenges into opportunities continue to propel this team forward.