As technology advances at an ever-accelerating pace, particularly in the realms of artificial intelligence and smart innovations, manufacturers face the added challenge of keeping up with these advances while not breaking the bank to fund them. Fortunately for them, this is where Lanco Integrated comes in.

Lanco takes the guesswork out of these challenges, thanks to its expertise and longevity as a global systems integrator of precision-engineered automation, assembly, and test solutions for multi-piece, high-speed production systems.

As a global integrator, Lanco has an expansive footprint—but with a specialized local touch, able to meet customers where they are. This is important for multinational customers, particularly those in the automotive, medical and life sciences, aerospace and defense, electronics, and consumer product sectors where tight tolerances, rapidly evolving technologies, and production values are top of mind.

As a problem solver, Lanco leverages deeply rooted design engineering, technological integration, and risk-mitigated project management to devise customized solutions, offer valuable market insights, and support a project through its lifecycle until long after installation is complete, which makes Lanco an enduring partner in automation.

Going global, staying local

Lanco Integrated is a legacy company, but one in evolution. The company dates back to 1873 in Switzerland, with origins in manufacturing watch components for Rolex. Through several iterations, acquisitions, and expansions, the precision engineering and automation specialist has positioned itself to support its customers wherever they may be, both geographically and in terms of market readiness.

As a global integrator, Lanco has had a presence in Asia since 2008, establishing an operation in Malaysia in 2021 to further enlarge its global footprint. This expansion allowed the company to flex its might as an integrator by bringing together two separate locations and unique cultures from opposite sides of the world to work seamlessly as a team. “We are a global company,” says President and Chief Executive Officer, Bob Kuniega, “but to be able to execute to that level—to deliver on your promise of ‘design anywhere, build anywhere, identically to one another’—that is a completely different game,” he says.

“The infrastructure has to be set up and the training has to be done; the business management systems and the processes and the forms and the tools all have to be in place, and everybody’s got to be using it all in exactly the same way.” This ensures that “everyone is working toward the same goal,” says Kuniega.

By engaging its people, creating a system of accountability, and blending established institutional knowledge with the ideas of the next generation, Lanco has continued to add value to its customers’ operations with its exceptional precision engineering capabilities and specialized market insights. As an ESOP (Employee Stock Ownership Plan) company, Lanco is uniquely differentiated from other businesses as its employees are also owners. The ownership mindset drives a heightened interest in not only satisfying customers but also ensuring profitability, as everyone’s individual success contributes to the collective success of the team. From Kuniega’s perspective, the company has the potential and opportunity to capitalize on fast-moving markets, both mature and emerging, to advance new products to market and scale up production to take advantage of unique market conditions.

“Whether it be tariffs and reshoring, or supply chain disruptions because of a pandemic, [conditions are] requiring our customers to scale up in the local markets where they have to supply their solutions, so we’re well positioned not only here in the United States because of our legacy, but also in Southeast Asia and the rest of the world through our facility in Malaysia,” Kuniega explains. He sees it as supporting those customers as they face rising costs, resource challenges, rapidly evolving technology, and highly competitive markets.

Embracing change

A significant part of the value delivered by Lanco is the team’s ability to anticipate customers’ needs, for today and for the future. “We have a modular solution,” explains Kuniega. “Each discrete operation is a self-contained module. For instance, if the control system within a module goes down, you don’t have to stop the whole production line.” This affords flexibility and the ability to adapt, reconfigure, and expand operations without the need for costly redesign or reengineering.

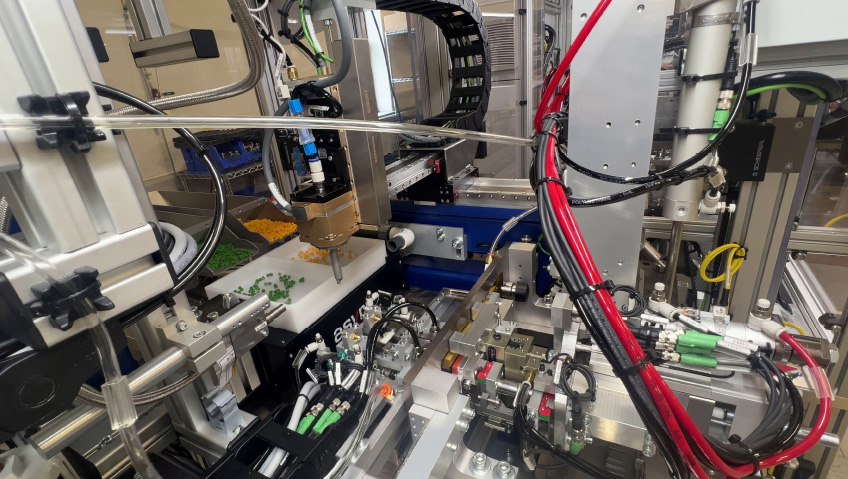

These modules comprise all the latest technologies, where needed, such as (take a deep breath!) vision-guided pick and place, dispensing, laser processing, various attachment solutions, multi-axis articulated robot-based mechanisms for material handling, feeders, transport systems, intelligent and smart devices and sensors, industry-leading programmable logic controls, PC-based network systems, and data management solutions.

Essentially, Lanco provides what Kuniega describes as “the glue that holds the whole supply chain together. We’re the best R&D for some of our vendors because we’ll test their products to the limit and in some cases, we’ll tease out some flaws in their software or their hardware and we’ll give them ideas of what they need to enhance their product so they can differentiate themselves.” He notes that this is all while ensuring that customers have the best available technological innovation at their disposal.

This approach is built upon the understanding that with technology advancing at a rapid pace, it becomes harder for customers to understand the breadth and depth of the technology, much less how to unlock its potential, as they may lack the intimate application and market knowledge that sets Lanco apart as an integrator. Lanco takes everything a step further by aligning with sectors where it can deliver the greatest value, leveraging its market insights, precision engineering, and automation expertise to not only add value but also mitigate risk.

Integrating risk management

This team is not only in the business of precision engineering and systems integration; it is also in the business of risk management, and a big part of this approach is centered on its Design for Automation principles, which are applied early in the design cycle to identify and address any potential process and scalability issues while avoiding the potential for costly delays and rework.

“We evaluate our customers’ products and processes, their competitors’ end-market needs, and trends, and engage our critical supply and technology partners as we embark on engineering the right solutions, tailored to address markets’ and customers’ needs,” explains Global Vice President of Sales and Marketing, Barry Rahimian.

From concept to the unique Design for Automation process—as well as data management, line integration, performance optimization, finalization, and post-installation support—Lanco Integrated remains a constant in a market of changing variables.

“At core, we are problem solvers, and we look for difficult automation projects where we can leverage our talents in design engineering, integration, and risk-mitigated process management to provide value to our customers,” Rahimian says. To this end, Lanco Integrated considers all commercial, technical, supply chain, quality, legal, project, financial, and environmental risks and provides comprehensive risk mitigation plans, potential backup plans, and strategies.

Supported by a well-defined and documented risk assessment process internally, Lanco Integrated mitigates risk for itself as well, which helps maintain its robust ability to step up to the plate for its customers. With over 1,000 days without a lost workday at its U.S. operations and pushing 700 days in Malaysia, its strategy and performance speak for themselves.

Future-forward

As part of its approach to forecast and mitigate risk for its customers, in 2024, Lanco established a “Futures” initiative that was, as Rahimian notes, “engineered to align our technology and innovation development efforts with our go-to-market (GTM) strategy, and which was fundamentally based on meeting the needs of our customers and markets.”

This is particularly important where speed to market, market share, and cost-related challenges are concerned, since, as he explains, “we don’t have anything off the shelf that people can order; everything is customized to customer-specific requirements. Everything we do is heavily tailored to their needs, so we have to anticipate our customers’ current and future requirements.”

Key to this value-add is a deeply rooted knowledge of the markets being served, which is why Lanco has undertaken a detailed and expansive market segmentation strategy to ensure its solutions are timely, relevant, and insightful, even where technology is forging ahead. The goal is to ensure that processes remain competitive in the one to two years it takes to implement them in the market.

“Markets will change and evolve in that time, so it’s critical for us to anticipate and be cognizant of the market trends and our customers’—and their customers’—needs and accordingly be able to plan proactively and make sure we keep their future requirements in mind,” says Rahimian.

“We want to show our customers that we know their application, their pain points, their challenges, and we want them to minimize their risk by going with a supplier who has done this over and over, who can bring to the table new thoughts that they hadn’t thought of before,” says Kuniega, referring to the way the company has proven itself through its performance for over a century.

It’s this ability of Lanco’s to evolve, grow, and stay at the leading edge of technological innovation and market trends that has proven to be a sharp strategy for its customers and its vendors. And so Lanco Integrated continues to prove that it is second to none as an automation and precision engineering specialist, capable of optimizing performance on the manufacturing floor while remaining profitable in the most competitive of global markets.