There’s nothing quite like the taste and texture of fresh-caught salmon, berries picked at the peak of their growth, or a pizza just out of a wood-fired oven. However, for all those consumers who don’t live on a farm near the ocean and close to a fine pizzeria, supermarket freezers are their only source for the fresh quality they love year-round. This means perfect color, taste, texture, and natural nutrients—all of which depend entirely on the quality of the cooling and freezing processes used.

Since 1990, Advanced Food Equipment (AFE), a manufacturer of premium quality cooling and freezing equipment, based in Ridgeway, Pennsylvania with facilities in The Netherlands, has emerged as an industry leader, empowering large commercial food processors to provide their customers with precisely the quality and standards they want.

Evolution of an industry

The cooling and freezing industry traces its origins back to 1820, when British scientist Michael Faraday produced a cooling effect by compressing and liquefying ammonia, and 1876, when German scientist Carl Von Linde finally developed an ammonia-driven system for making ice. But it wasn’t until after World War II that commercial walk-in freezers were introduced, making possible large-scale storage and freezing of perishable foods, gradually replacing traditional ways to preserve such as pickling, salting, and canning. At first, the results were far from perfect, with freezer-burned meat and fruit and vegetables that turned mushy when thawed.

AFE’s founder, Mike Webber, has had a long career in a still-evolving food industry, “with a focus on freezing, working for several different companies before deciding he wanted to start his own,” says Ryan David, AFE’s Director of Sales.

“His experience in the industry, before starting AFE, made him want to do something better because he saw a lot that could be improved in the cooling and freezing sector,” David explains, “From the beginning, the company has emphasized solving the needs of customers, with a focus on hygiene and quality, because Webber wanted to offer equipment that stood above the rest.”

Webber has remained active and involved in AFE, which began as a small family-owned operation and has since grown into a global player. Today, it is led by President Ben Brechtell, who came to the company in the 1990s as part-owner.

And the company’s scope has certainly grown. “We sell, install, and service the food processing equipment we manufacture throughout the U.S. and Canada; in Central and South America; in Europe; and we have some in Saudi Arabia, where an installation is happening now. There’s no geographical limit to where our equipment can be installed,” David says.

Cutting-edge equipment

AFE’s industrial freezers and refrigeration equipment adhere to CSA, USDA, and OSHA standards and exceed industry standards for health and cleanliness. They are carefully crafted from stainless steel, eliminating any joints or crevices that could trap food particles and thus inhibiting bacterial growth. The equipment also has HTST (high temperature short time) pasteurization capabilities.

“We work with several entities, including the American Meat Institute, who have come to our facility and evaluated our equipment from a hygienic and sanitary point of view, and they rated ours as the most hygienic they have ever inspected,” says David. “We want to make sure that food-related disasters don’t happen, and we’re proud that our ratings are so high. It’s something we hang our hats on, and we constantly look for ways to improve.”

Food processors in all sectors (beef, poultry, and pork; seafood; fruit and vegetable; pizza and pasta; dairy products; baked goods; potatoes, fries, and chips; and more) can choose from a wide range of applications to suit their specific needs.

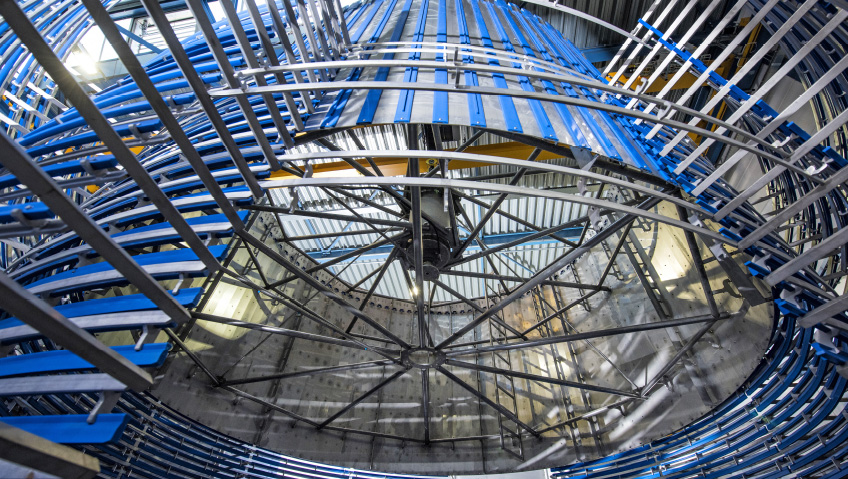

Spiral freezers, designed for faster freezing and lower energy consumption, are available in three formats: the Packaged Spiral Freezer, which is available in single to multiple pieces that can be installed in days instead of weeks; the External Spiral Freezer, which is completely built offsite, and attached to the exterior of the facility with no special foundation or roofing requirements; and Site-built Spirals.

This latter solution is offered for installations where modular sections cannot be utilized and incorporates the same design methods. Also within the spiral family are Spiral Steamers, with varying cooking capabilities, and Spiral Coolers, providing ambient or conditioned cooling environments ideal for sensitive food products.

AFE’s IQF (individual quick freeze) Tunnel Freezers, including Belt Tunnel Freezers and Hybrid Tunnel Freezers, can handle a wide range of processes, and are ideal for processing small meat products as well as many varieties of fruits and vegetables.

The company’s Contact Belt Freezers, meanwhile, provide fast freezing times with minimal hydration, making them ideal for products like raw meat, seafood, candies, baby food, dairy products, fruit processing, and ready-to-eat meals.

Also available are energy-saving Multilevel Box Freezers, Plate Freezers—a thermally effective solution for food in packages or trays—and Blast Freezers. The AFE-30, the high-capacity, centrifugal evaporator fan on these freezers, draws air through the load to ensure even temperatures and is ideal for high-volume food preservation.

In addition to the cooling and freezing equipment, AFE manufactures Shakers, which are used for sorting products by dimension and length, aiming or orienting products, de-watering, de-fatting or degreasing of products, spreading or singling, sieving, grading, or dosing.

Efficiency and the environment

AFE’s engineers have implemented design features that are beneficial for customers, end users, and the environment.

The sequential defrost feature, for example, can save up to 30 percent in energy costs. As David explains, a freezer could have 10 coils or evaporators, manufactured from aluminum and magnesium to make them corrosion resistant, a concern because they change temperature often and can only run for so long.

To protect their life span, AFE’s design allows for one coil at a time to be isolated from the enclosure and shut down while it is defrosted, resulting in no lost production because the other coils are designed to handle the full capacity while one is out. This allows the freezer to operate for much longer periods.

With regards to cleaning, AFE has designed a CIP (clean in place) system, engineered to clean a very large area in a short time. It uses less water and detergent, ensures hygiene, reduces downtime and overall operating costs, and extends the life of the equipment.

The good news for any commercial food processing company is that they needn’t be an AFE customer to take advantage of this top-flight cleaning system, because AFE technicians can install an engineered retrofit CIP package into an existing Spiral Freezer or IQF Tunnel system from another manufacturer.

Reliable and timely service

AFE works with teams of service technicians located strategically throughout North and South America, managed centrally from its Ridgeway, Pennsylvania office, who carry out preventative maintenance as well as quarterly, biannual, or annual inspections and on-site freezing and chilling testing to ensure equipment is running optimally.

“But, much as we try to prevent issues arising, things come up that we need to respond to quickly,” David shares. “We recognize that time is money, especially in the food industry, so if a freezer is not working, it’s not making money for our client. We pride ourselves on quick response times, finding solutions, and being in constant communication with our customers to make sure we know what their needs are,” he says.

“There’s a misconception in the industry that AFE is typically more expensive than our competition, but if potential customers compare our equipment with our competition and review the value-added options we offer—the hygiene and the longer run times—then there’s no comparison,” he continues. In actuality, “AFE is less expensive because we offer more value in the long term. Return on investment is a big point of reference, and I like to point that out. As we move into the future, companies are paying more attention to hygiene and efficiency and longer run times. We see those trends happening now and we’re taking steps, using the newest technologies to run our freezers even more efficiently with longer run times so our clients can be even more profitable.”

On a personal note, he calls AFE “a great company to work for. With all the talk about food security, I take pride in being part of the process that can provide clean, safe, good-tasting food to the world,” he says. “One of the things that can get lost in the shuffle while we talk about the huge pieces of steel equipment we sell and install is that this equipment has a real impact on individual lives. I am happy to be working for a company that believes food security on a global scale is paramount.”