When shiny new objects leave the factory to enter the marketplace, no matter how varied they are, they all have one thing in common: whether SUVs or speed boats, medical equipment or consumer goods, they owe their existence to custom die cast dies and plastic injection molds, tools supplied to product manufacturers by specialist engineering and mold-making companies.

It is no stretch to say that those companies are both the foundation and the unsung heroes of America’s entire manufacturing industry. Without them, mass production could not exist.

We spoke with Mike Hetherington, President of Franchino Mold & Engineering Company (FMEC), the ISO 9001:2015 certified company based in Lansing, Michigan, which serves cutting-edge manufacturing customers across the U.S. and around the globe in the automotive, aerospace, agriculture, construction, consumer goods, furniture/household, marine, and material-handling manufacturing industries.

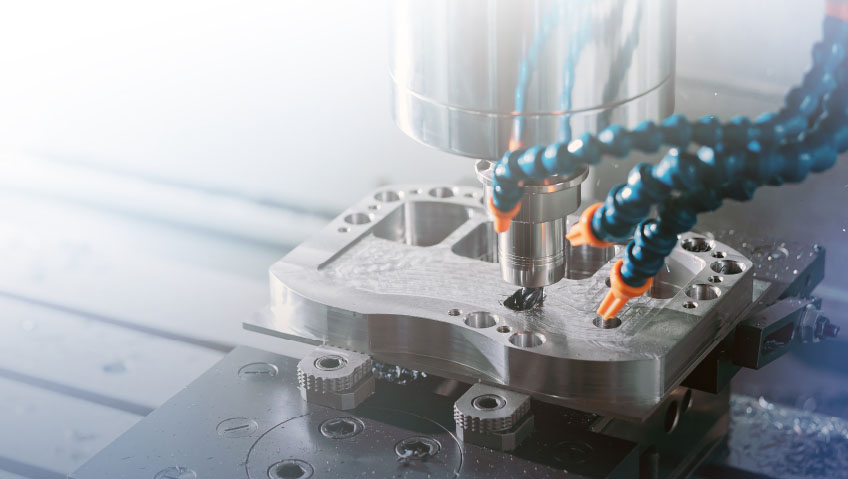

FMEC is an industry leader in the design and engineering of medium to large die cast dies and plastic injection molds, which include high-pressure (from 1200- to 8500-ton) injection molds, gas-assist molds, structural foam molds, compression molds, and stack molds. In addition, it offers contract machining, preventive maintenance, and mold/die repair services.

Hetherington, who joined the family-owned company in 1997 as a designer and worked his way up to Manager of Engineering and Vice President of Operations before becoming President in 2020, tells us the company got its start in 1955 when Richard Franchino began working out of his garage in Lansing, Michigan. Six years later, in 1961, he moved into a larger standalone facility.

His son Robert (Bob) joined him in 1974, with a mechanical engineering background. Together, they continued to build the company based on the highest level of craftsmanship. Bob’s son, Kent, Vice President of Operations, joined the company in 2012 and his daughter, Hollie Rusthoven, Director of IT, joined in 2015.

“At one point we had three facilities in Lansing, one in Jackson, and one out of state, but since have combined all the facilities and operations under one roof,” explains Hetherington. “Now we take up 98,000 square feet, 78,000 square feet of climate-controlled space, which includes a recent 18,000-square-foot extension.”

He goes on to explain that this expansion (80’ x 225’ x 50’) is a dedicated mold-making area, with an 80-ton main crane and four 25-ton auxiliary cranes, “for our guys who are putting our molds together. Each has their own area set up with air, electric, water, and overhead cranes. Everything is at their fingertips, so they’re not stopping to look for anything.”

From inception to the present, Hetherington says FMEC’s goals have remained constant: “To produce results with products that exceed our customers’ quality and schedule expectations, while providing growth and prosperity for the company and its employees.” The key to the company’s success, he believes, is in its focus on people, process, and technology. “If we can get those three things right, then everything else falls into place.”

FMEC considers its people to be its greatest strength, with Human Resources Manager Brad Rusthoven playing a key role in attracting and retaining the most skilled, qualified, and motivated people in the trade. Employees are hired, reviewed, rewarded, and recognized based on how closely they are aligned with the company’s core values of teamwork, hard work, innovation, trustworthiness, and integrity.

As Rusthoven explains, “We want an employee who: 1. Gets It, that is, one who truly understands the role, knows what’s expected, comprehends the culture and core values; one who 2. Wants It, who is interested and motivated; and one who has the 3. Capacity, the knowledge, experience, or education to do the job, and the necessary physical, emotional, and mental capabilities. We would prefer to spend our time training the right person who shows they have the character to do the right thing and work as part of a team.”

While many of FMEC’s employees have been with the company for 20 or more years, the company recognizes the importance of continuing to recruit and train new employees who will be ready to take the place of retirees. Currently, eight of the 85 employees are apprentices.

To that end, Rusthoven spends a considerable amount of time visiting local career centers, talking about the advantages of a career in the industry, and working with students through the company’s internal apprenticeship program. This valuable program leads students through to qualifications as CNC machinists or mold-makers, along with students at Lansing Community College also enrolled in the Manufacturing Engineering Technology program as designers or machinists.

“Brad does an excellent job working with career centers and local schools and because of that we are ‘a preferred employer,’” Hetherington says. “We get an opportunity to talk with the top students prior to graduation. We are proud of our apprenticeship program because it provides the apprentices with the technical and personal skills needed to succeed in the workplace.”

On the retention side, Hetherington cites the company’s clean, safe, climate-controlled workspace, where employees earn competitive wages and undergo annual performance reviews based on key performance indicators which help everyone stay on track and understand what is expected of them.

The process begins with the seven-member leadership team, including Hetherington and Rusthoven, who participated in offsite training days, learning how to become effective leaders. They work on communication and conflict management skills, and on developing an understanding of how their leadership can impact company culture and how that culture in turn impacts productivity. Based on that learning comes the establishment of leadership team goals, which starts with a positive, strong, productive, and yet open culture. The group also provides vision and strategic leadership to meet the cost, quality, and delivery expectations of customers; and ensures continuous improvement by tracking data and responding accordingly.

“We are data-driven, and we base our decisions on our key performance indicators of safety, quality, delivery, and cost. We have internal matrices that define what we are doing well, that ask if we are doing what we should be doing, and do we have room for improvement in any of those four key areas,” Hetherington explains. “Then we follow those KPIs into the work centers, because each one of those centers has safety, quality, delivery, and costs they are responsible for, and the team leader in that area ensures the center is meeting those goals,” he says. “From there, we waterfall it down to the individual’s performance reviews, so it goes all the way down, from the corporate level to the individual.”

To keep it all organized, FMEC has developed sophisticated tracking tools that support a clearly defined workflow process beginning with the RFQs and continuing through the job release, engineering, purchasing, planning and scheduling, production, quality, assembly, and delivery phases of every project. These tools also allow management to determine capacity week by week for months in advance and adjust workloads on time so that schedules are met and downtime is eliminated.

Since its inception, FMEC has invested in the best technology available and continues to believe that research and investments that increase capacity and improve efficiency are crucial to its success. FMEC has all the equipment one might expect from a manufacturer of this size and scope. There are multiple boring mills, CNC mills, 21 CAD/CAM workstations, grinders, lathes, cranes, drills, MIG and TIG welders, laser scanner inspectors, and transportation/delivery vehicles.

But over and above these, there are some exciting new acquisitions, because, as Hetherington tells us, “Our goal is to find and obtain technology that is advanced, flexible, and automated.”

One of the newest and truly significant investments is the Hermle C650 5 Axis Machining Center with a 14-pallet changer. “This is a crucial piece of equipment for us to become more automated because the 14 pallets allow the machine to work when we’re not here,” Hetherington explains. “Our operators load workpieces into the carousel, and when the operation is finished with one workpiece, the robot takes it out and replaces it with another from the carousel, so it’s not waiting for an operator to load and unload the machine.”

These factors—people, processes, and technology—combine to guarantee that the die cast dies and plastic injection molds that are designed, engineered, and built at FMEC’s plant will be of the highest quality, ensuring that the products its customers produce with those tools will be of the same high quality.

“We’ve been extremely fortunate with our workload that our customers have entrusted us with in the past,” Hetherington says. “With our ongoing continuous improvement in people, process and technology, we are excited about the future of FMEC, our customers, and our team members.”