Offering more than 135 years of combined expertise developing, producing, and repairing gearboxes for heavy-duty applications worldwide, Horsburgh & Scott has effectively established design guidelines for gearboxes with capacities of up to 5000 HP and four million lb-ft of torque in a rev range from 0.5 to 3600 rpm.

In addition to providing a full range of industrial gearing service and repair options, the company’s top concern is adhering to its manufacturing timelines by offering a thorough assessment and work scope before starting any job. Furthermore, as H&S stocks its own components, the typical six to 10-week process can be completed in as few as four weeks while rebuilds can be even quicker.

In short, this company is continually looking to make business-changing improvements, be it through product offering or market diversity.

Diversifying markets

“Horsburgh & Scott is a 138-year-old company that has historically been focused on metals and mining. In the seven years since I’ve been in the President/CEO position, we’ve worked hard to be much more diverse in our market presence,” says Randy Burdick. “Now we’re in anything that requires gears, from energy to oil and gas to chemical processing; from cement to sugar to tire and rubber. We’re much more diverse in the markets we serve now than ever in the history of the company.”

This opening up of new opportunities has brought an impressive quadrupling of business in the past seven years, Burdick says.

In keeping with its commitment to change and growth, the decision to acquire a facility in Louisiana came about in part due to the lure of a tremendous talent pool that the company could tap. “By acquiring the facility, we’ve also acquired a group of very talented employees that supported that site,” says Burdick. “We also see the Gulf Coast as a target-rich environment for our products and services.”

As Horsburgh & Scott services the power transmission industry as it pertains to gear drives, closed gear drives, loose gearing, and field service, it does a “tremendous” amount of business along the Gulf Coast in the petrochemical, oil and gas, and pulp and paper industries.

Propelling the Navy

H&S is also manufacturing new U.S. Navy propulsion systems, which will be produced in a 32,000-square-foot facility in Slidell that has been created to repair, maintain, and assemble industrial gears and gearboxes for the defense sector.

“That’s part of our growth initiative and strategy,” Burdick says. “We’ll grow that facility as that contract matures and bring in additional business to justify the expenses to continue to grow that footprint.”

The $4.9 million capital investment in St. Tammany Parish, Louisiana—the result of the recent defense contract award and growing demand for the company’s products and services—will also directly create 40 new jobs with an average yearly income of more than $100,000. In the southeast region of the state, Louisiana Economic Development projects the creation of an additional 57 indirect employment opportunities, for a total of 97 possible new jobs.

According to Burdick, the H&S Slidell Service Center will assemble U.S. Naval propulsion drives that will be put to service protecting the sovereignty of the nation and U.S. allies. In addition, to service the commercial and military marine markets more completely, H&S has established its Industrial Marine Gearing Solutions subsidiary, offering 24/7 field service, gear and gear drive rebuilds and repairs, and ABS-certified gearing solutions. Propulsion drives, pump drives, winch drives, dredge pumps, alignment-free drives, and other goods are included in its line of marine gear.

To combat expensive downtime in the marine industry, Horsburgh & Scott will offer the fastest turnaround times in the industry thanks to its quality service technicians and durable ABS-certified gearing solutions that can withstand demanding usage. H&S also offers drop-in replacement drives and OEM spare parts to minimize downtime, and can repair or rebuild most gearbox brands with improved engineering specs. Additionally, the company can provide value-added services to its maritime clients, including comprehensive bore scope inspections, non-destructive testing, in-house carburizing and heat treatment, and more.

“We do brand-new, custom-engineered design and manufacture of U.S. Navy boxes and propulsion systems, and we’re undertaking repair of tugboats and dredge applications, pump cutter heads, and ladder drives for the marine industrial support side of our business as well,” Burdick explains.

Always essential

Considering the incredibly wide variety of industries that need gears and manufacturing processes, it’s no wonder that Horsburgh & Scott was not only considered essential at the height of the COVID pandemic, but did not need to lay off employees or reduce hours.

“We were hiring during COVID because there was a demand,” Burdick says. “One of the big issues during the pandemic was the U.S. market was offshoring gear manufacturing for various reasons including talent and cost. During COVID, Asian and European companies couldn’t get product or service technicians to the U.S., and people couldn’t get assistance because there was no one available to support product manufactured offshore. So, in the past three years, there’s been a tremendous push to re-onshore gear manufacturing back here in the United States.”

Horsburgh & Scott has benefited from this development by winning new business opportunities not previously available.

“Once COVID happened and people started looking for options and they realized that Horsburgh & Scott manufactured 100-million inch-pound gear drives for the mining sector or the steel sector, certainly we could manufacture a 10-million inch-pound gearbox for the cement sector,” Burdick says. “We had a lot of visitors, and we tripled our sales force to make sure we were reaching the right customers and giving them the customer focus they’re looking for.”

During this time, H&S also expanded its product offering to include field service. If customers couldn’t come to the company, Burdick says, the company would go to them, with trucks and trailers and all the essential tools to undertake inspections and comprehensive repairs on-site, ranging from laser alignment equipment to borescopes to portable milling machines for full comprehensive repairs.

“Where gear drives can’t be taken out, we’ll go to that customer’s site, rebuild or overhaul their equipment, and do that in a very expedited way,” he says. “Customer centricity is broadly used, but we’re a 24/7 company. We work 24 hours a day around the clock, seven days a week. That takes a certain type of character and a certain level of commitment by our employees.”

Customer centricity

“Customer centricity is key,” says Burdick. “Speed kills the competition, and we drive that throughout the organization. That culture of speed of response applies to everything we do, from the time we answer the phone to replying with a quote to shipping product.”

Maintaining that level of service also drives the company’s need to make acquisitions, Burdick adds. “We’re looking for acquisitions out west to get closer to our customers there in the mining sector; they don’t want to send gear drives all the way across the Rocky Mountains to the Midwest. We’re also making acquisitions down on the Gulf, really driving that customer-centricity focus and delivering that difference in everything we do.”

H&S is hot on talent acquisition, too, building its talent through hiring people, giving them better job training than they’ll get elsewhere, and expanding its workforce both internally and externally.

“We’ve also tied in with some really good customers that are the leaders in the industry,” says Burdick. “When they toured our facility and met our team, they saw the passion and our capabilities for vertical integration. We don’t talk the game, we deliver it.”

Owning the lifecycle

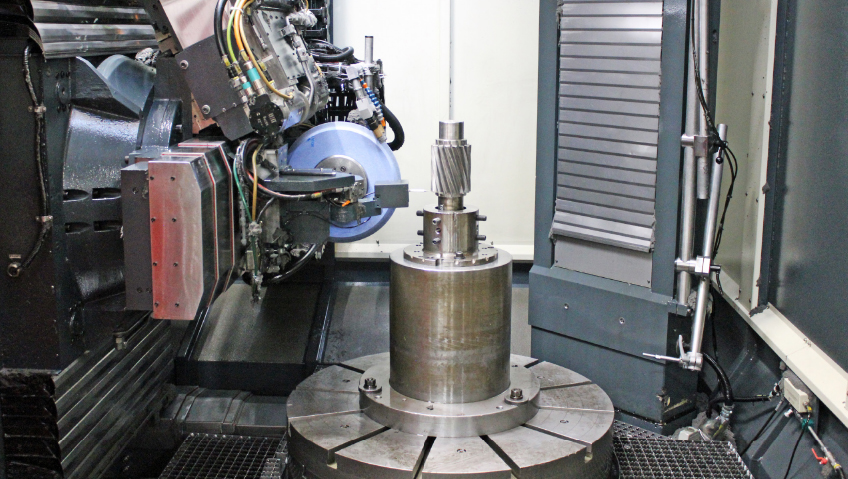

As a vertically integrated company, H&S fabricates, heat treats, cuts, manufactures, and designs its own gears, and also handles installation. “We really own the product lifecycle of our products, but we can also reverse-engineer competitive product and make it better and more reliable,” Burdick says. “That’s the unique difference we bring to our customers over a traditional gear manufacturer that’s focused only on their core offering.”

In terms of service, gearboxes don’t fail according to a company’s prescribed schedule, Burdick adds; they usually just fail at the worst times, which is when Horsburgh & Scott has to respond—and immediately.

“We certainly never tell the customer, ‘I’m sorry, we’re too busy,’ or, ‘it’s a holiday weekend, we can’t get to you,’” he says. He adds that H&S employees are committed to sacrificing their personal time to ensure that when customers call, there’s somebody available to service them at the highest level.

“That was a culture change,” he says. “That wasn’t something that was initially part of the DNA of this company. It’s been developed over the past seven years.”

Owner GenNx360—a private equity firm that invests in industrial and business services companies—has invested heavily in Horsburgh & Scott, which has enabled the company to grow with vigor and make the acquisitions necessary to build top-class product and customer portfolios.

“Without that support, we couldn’t do that,” Burdick says. “We’re now in a position where customers are seeking us out to drive speed and response on a breakdown, or for a technical matter where they’re having repetitive failures or reliability issues. We’re being brought in to help resolve those problems and we’re doing it better than anybody in the marketplace.”