If ever there was a boutique broker of bulk material supplies, CREMER ERZKONTOR (formerly Possehl Erzkontor), the parent company of CREMER ERZKONTOR North America (CENA), is it. That is why increasing numbers of big manufacturers—especially in steel—look to this company to mitigate the risks in procuring raw materials and minerals from abroad. Founded in the early 1900s by the international materials trader Emil Possehl in Lübeck, Germany, it has earned itself a reputation for international raw materials trading excellence in the industry.

Since 2020, however, the company has also been breaking new ground, as reflected in its name change in 2023. With the name change, ERZKONTOR is moving closer to the Hamburg-based family business CREMER, which took over the shares of the Lübeck-based raw materials trader in 2014. With the name change to CREMER ERZKONTOR, the more than 100-year history of Possehl Erzkontor is opening a new chapter.

The name change is a statement. The path the company is taking leads from pure raw material trading to the management of its customers’ raw material supply. In addition to logistical services, warehousing, and laboratory services, this also includes the processing and recycling of these materials in its own facilities.

CREMER ERZKONTOR North America (CENA) is an end-to-end logistics and raw materials, chemicals, and trace-elements supplier. From its local headquarters in Cincinnati, Ohio and nearby warehouse facility, the company’s reach spans the globe, with materials arriving in different specifications and grades.

There are also sister facilities in Proctorville, Ohio, in the Tri-State region of West Virginia and Kentucky. Other locations include Pittsburgh, Pennsylvania; Chicago, Illinois; and the Alabama region, from which the team manages ocean freight, barge, and domestic road haulage to ship gargantuan cargo volumes from global suppliers to end users on home soil. Among its services are sourcing, processing, sizing, testing, packaging, warehousing, and inspecting raw materials. A dedicated chemical facility and a focused sustainability watch round off the offerings.

The company’s strength lies in its longstanding relationships with suppliers as far as Kazakhstan and beyond. Some of these relationships span more than three decades, and the team doesn’t trade with companies they don’t know personally. This thoroughness in ensuring that the correct procedures, certifications, and packaging to pass customs are followed at all times is a matter of pride for this team of industry experts.

Niklas Lüdemann exchanged his position as the head of the European region to join the company’s United States team in 2021. In October 2022, he became head of the North American region and the head of key account management, making it a big year for him and the company alike. His principal function is still ensuring that all global clients get the best service and prices possible. The company is also expanding its presence down the West Coast as far south as Latin America and even into Asian markets, making Lüdemann’s new roles crucial to the company’s success.

But these were not the only recent shifts in the company’s structure. Toward the end of the first quarter of last year, CREMER ERZKONTOR appointed new Chief Financial Officer Nils Fleig, the former chief financial officer of MIAS Group in München, Germany, and it introduced Nicol Tomaschewski, who is fluent in Mandarin and is based in its Lübeck-based European headquarters in Germany, as its new head of Asia. The company also opened a new subsidiary in Chennai, India headed by Subsidiary Director Ananthanarayana Nonavinakere, giving the company a new point of contact from which to serve its Indian customers and suppliers. And in May of this year, the company welcomed a new second Executive Director, Roberto Wurst, responsible for the Chemicals Division, Key Account Management and the Latin America, North America and Asia Regions.

As the business has doubled in size annually for the past few years, more hands and minds were needed to make it all happen. Today, the company has a brand new finance team and a larger supply chain management team than ever. It has also expanded its number of sales personnel, ensuring that more customers can benefit from its growing services. As a result, the company continues to grow and hire.

Working in modern, technologically-advanced ways, team members benefit from the freedom to work from wherever they like. Staff train in Germany to learn the intricacies of the trade before they are welcomed to the market and provided with all the support they need to succeed. The result is a dedication by people who treat the firm and every customer as their own.

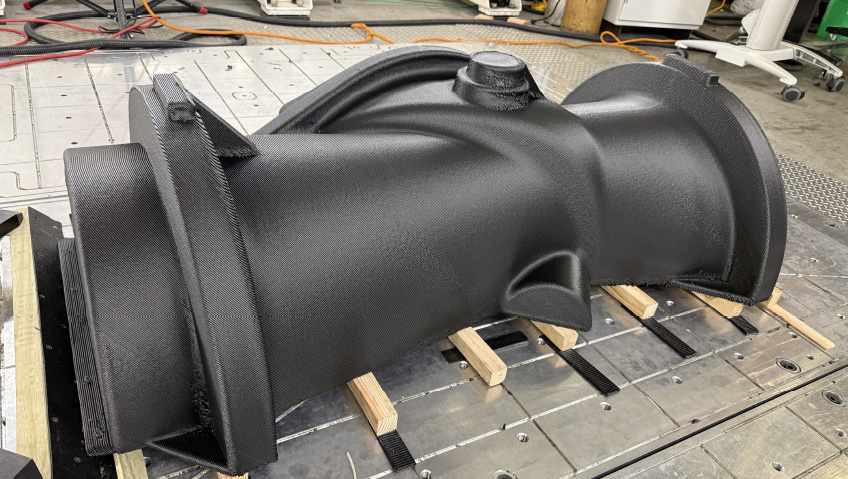

The natural environment is also considered with great regard. To this end, the company started taking steps toward improving and expanding its recycling activities. “I think this is a business for the future. We started a recycling plant in [Ohio to] recycle used refractory bricks from the steel industry,” Lüdemann says. While recycling refractory bricks from steel production is compulsory in Europe, it is only really beginning to catch on in the United States, and CREMER ERZKONTOR North America is leading the way.

As these bricks and the steel industry as a whole have a typically high carbon footprint, this initiative contributes considerably to lightening companies’ environmental footprint. It also brings down the cost of manufacturing new bricks, making the service an all-around win for steel manufacturers.

Another initiative brings new mining activities to its portfolio. Since early this year, a new facility, in collaboration with America’s only licensed fluorspar mine, brings this precious mineral to the local market for use in steel production. As the entire country is currently tied into trade agreements with Vietnam and China for this material, the new venture promises to be hugely successful as it secures precious supplies for American steel production. It also reduces lead times from several months to weeks while providing better quality than Asian sources. In addition, the quality of Utah-mined fluorspar is significantly better than what is currently available from Mexico’s dwindling resources.

Growth remains constant. In 2021, CREMER ERZKONTOR North America implemented an expansion plan which dictates that, by the final quarter of next year, at least half of its revenue will be from innovative new services that complement and raise the bar on simply buying and selling materials.

“Everything we do is targeted in that way to find more business. That allows us to reach our goal,” says Lüdemann, who points out that this will be achieved while not neglecting the traditional business aspects.

COVID-19 caused the company significant headaches through supply chain challenges, altered timelines, and raw material shortages over the past three years. Holding this all together while growing rapidly took considerable courage. “The team went through a lot. But they managed it all in a really good manner. In the end, what it comes down to for us is that it is all about our team,” Lüdemann says, noting that employees “add all the value.”

Raw materials shortages of the past two to three years included micro silica, magnesium carbonate byproducts, and much more. The next challenge was the truck driver shortage driving tremendous pressure on delivering containers. To protect its customers, the company shouldered much of the increased expenses for a while. Probably one of its most significant achievements during this time was that all its customers remained in production which is a considerable accomplishment by any standard.

Another hurdle manifested when Russia declared war against Ukraine. “We had several chemicals that came out of Ukraine and minerals and raw materials that came out of Russia. These completely stopped,” Lüdemann says. Instead of halting production, the team set off to find alternatives to replace Russian and Ukrainian components for every client. In the process, the company also did its best to find these new materials at a lower cost than the original imports.

Then there was a notable drop in the Euro and inflated interest rates to navigate. Ensuring good cash flow during this time was a challenge but the team did phenomenal work in keeping all its moving parts intact. The turnover of working capital it typically invests in paid-for materials was significantly slowed by long-haul ocean transit but was managed prudently. The company not only pulled through; it thrived.

Once this negative tide turned and spending habits returned to normal, the CREMER ERZKONTOR North America team had its work cut out, attempting to honor the avalanche of orders that suddenly streamed into its offices. This positive upturn inspired the firm to invest in processing capabilities that allowed it to hedge somewhat against the rising costs of materials and labor.

“I do not think we can complain about the outcome. Like most companies, we had a very successful 2022; we are happy with how the year ended. We look forward to 2023,” says Lüdemann.

The company has experienced staggering growth which went from around 40 million USD in sales in 2017 to about 200 million USD in only five years. As material prices are down, predictions are that its best growth will come from the metric tonnage it will ship in 2023 rather than from the minerals directly. Diversifying will bring further growth as it expands its mining, recycling, repackaging, and other value-added services.

2023 poses fresh challenges in need of new solutions. The closure of the Illinois River between April and August this year led CREMER ERZKONTOR North America to help its customers dependent on this Mississippi River tributary for their material supplies to stock up in good time. “Making sure they buy enough and at the right price was a big topic for us. We feel very comfortable with the position that our customers are in,” Lüdemann says.

With expectations for continued strength in the American refractory and chemical industries and much confidence in its capabilities, CREMER ERZKONTOR North America is well on its way to continue expanding and keeping its plans for supply chain diversification on track.