The current manufacturing landscape has very little in common with the state of the industry four decades ago. Today, it is a highly competitive global industry, not one for the faint of heart. Leaders of manufacturing businesses have a decision to make: is the only option to compete on the basis of price with low-cost manufacturers overseas? Or is it better to focus on innovation, using the best technology and talent available to provide a high quality product at the best possible price?

Enrico Giannetti is founder and President of Dorian Tool International, and he has made his choice.

“The competition from all over the world is fierce,” he says. “Dorian Tool can’t compete with low-cost products coming from some of these countries; instead, we focus on developing high-tech products for customers that demand high performance.”

Giannetti is no stranger to pivoting when needed. He opened a machine shop business in 1980 in Houston, Texas, and that shop served some of the major international companies in the energy sector located in Houston and Dallas at the time: Schlumberger and Otis Engineering, among others. It quickly grew to be successful and profitable—at least, that is, until the spring of 1982.

Through the early 1980s, the oil industry crashed. Adjusted for inflation, prices plummeted from around $140 per barrel coming into the 1980s to less than $30 per barrel by the middle of that decade. Needless to say, there were severe consequences for any oil-related business, including Giannetti’s machine shop. It would have been understandable if he had simply folded and moved on to other pursuits. He did not.

“We had to evaluate our options and make the best decision in accordance with our situation,” he recalls. “In 1984, we moved all the equipment into our property in East Bernard, about 50 miles southwest of Houston, and a new Dorian was born.”

Today, the company employs about 50 people. Apart from Enrico Giannetti as President, other key staff includes Yolanda Giannetti as Vice President of National and International Sales and Director of Administration, Human Resources and Customer Service; Sarah R. Ortega-Durón in Marketing; Douglas Amerson as Operations Manager; Hector Chavarria as Manufacturing Product Manager; and Baris Cezaroglu, Vice President of Engineering and Manufacturing.

That team and the talented people with which they work produce and sell a wide range of high-end machining products to a nearly limitless range of customers.

“Our customer list includes automotive and aeronautics manufacturers, medical equipment manufacturers, companies in the energy industry, and the Defense Department,” says Giannetti. “From a hobby shop to a large manufacturing company, anyone that does any kind of manufacturing could be our customer.”

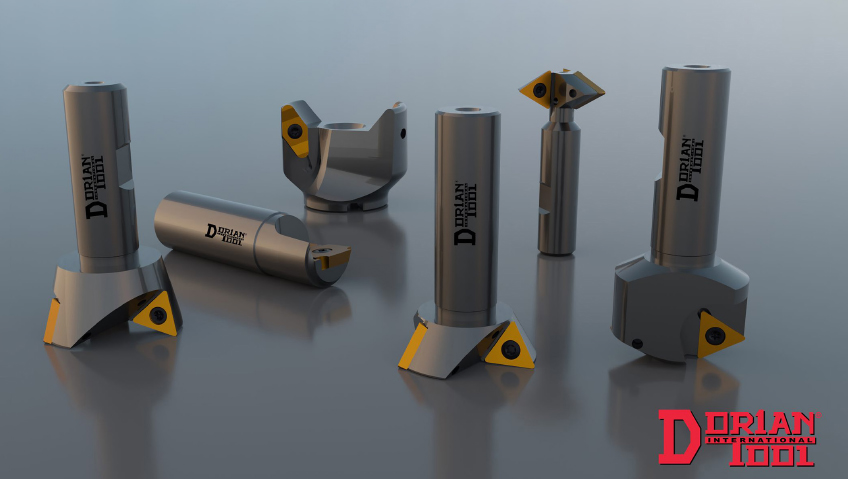

To those customers, Dorian supplies tools engineered for cutting, knurling, turning and boring, threading, and grooving metal on both CNC and manual lathes and systems for holding those tools. It is perhaps in this latter category—the company’s tool-holders—where its innovation is most clearly evident.

The company’s tool posts hold multiple patents, with industry-leading indexing and locking technology. Its quick-change system—a universal boring and milling bar with quick-change tool heads—offers significantly increased efficiency, leading to less time spent changing tools.

Digging even more deeply, the company’s components and parts also employ unique innovations that allow its customers to save time and money.

For instance, each Dorian ER collet—the part that secures the bit in a cutting tool—features 16 full-length slits, in contrast with the eight more typical in competing companies’ collets. This allows the collet to collapse much more uniformly, providing a concentric 360-degree gripping surface for the tool and reducing component wear and tear.

Dorian’s proprietary vibration damping system absorbs vibrations caused by cutting tools, offering better accuracy and surface finish in addition to longer tool life. The company’s components also offer a through-coolant system, supplying coolant to the cutting edge for improved tool life and, therefore, reduced costs.

As he operates a manufacturing business which, in turn, has manufacturers as its customers, Giannetti is understandably passionate about the industry.

“Manufacturing is the pillar of a stable economy in any country in the world. At Dorian Tool, we’re proud to produce some of the highest-tech and high-performance toolings in the world. We bring our tools and technology to our customers—other manufacturers—helping them to become more competitive and profitable as well.”

The ‘international’ in Dorian Tool International’s name is no exaggeration. Its customers are global, as is the company itself, with international sales representatives located in Germany, Canada, Italy, Mexico, and China.

The team also participates in trade events that expose its products to potential customers around the world. The International Manufacturing Technology Show (IMTS) is held every two years in Chicago, and Dorian Tool participated in the 2022 event. It also participates in AMB—the International Exhibition for Metal Working—held annually in Stuttgart, Germany.

A global approach makes sense as manufacturers of all sizes and types face a host of challenges: competition from around the world, pressure on prices, skyrocketing costs, and more. When asked about the most serious difficulty facing his business, though, Giannetti answers quickly.

It is about people: “Finding new employees is the greatest challenge in our industry,” he says.

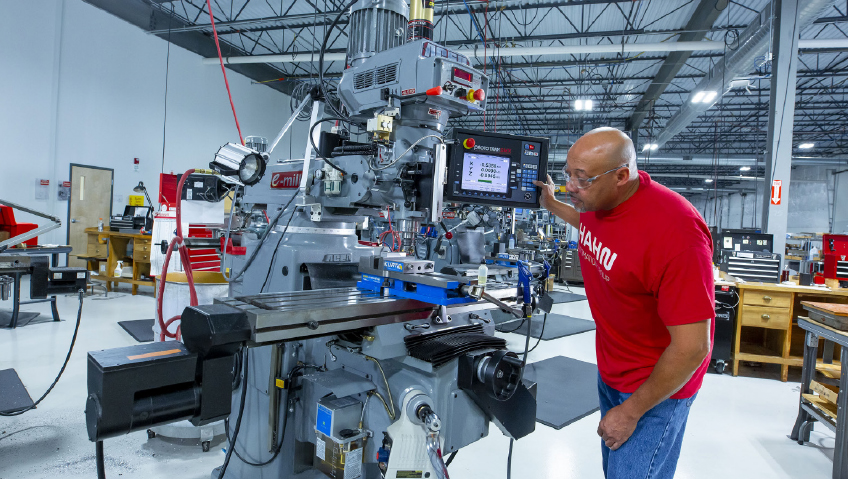

The difficulty is that in today’s world, manufacturers like Dorian Tool exist in a constantly changing space between the traditional labor-intensive nature of manufacturing and the current high-tech form of the industry.

“Too many young people—the next generation—are not interested in working in a manufacturing plant,” says Giannetti. “There is still a lot of manual and physical work involved in the job. At the same time, though, in today’s machine tool industry, most of the equipment is driven and controlled by computers. Without a good education, knowledge, and experience, it is very difficult for anyone without proper preparation to operate a CNC (computer numerically controlled) machine tool.”

Dorian is routinely in need of CNC machinists, mechanical engineers and programmers, sales engineers, and technical leads. To overcome the hurdle presented by a shortage of talent, the company has put a number of strategies in place, tightening its procurement focus for capital equipment and purchasing advanced equipment that can operate with less human input.

“In the manufacturing department, we are changing and simplifying the manufacturing process and getting new equipment which will help us to overcome the manpower shortage.”

As manufacturing technologies and equipment evolve, so too will the industry, and Dorian Tool International will continue to evolve and change direction as it needs to as well. This company will not let the race for the bottom in price and quality distract it from its focus; instead, it will innovate, develop new tools and products for its customers, and constantly raise the bar for quality.

To power the future of manufacturing in America, Enrico Giannetti has one hope; his passion for the industry is clear, as it is a rallying cry shared by manufacturers across the country and beyond.

“Expand education in manufacturing technologies,” he implores. “Get young students thinking about our industry and fill the classes with them, creating a new wave of personnel to fill the shortage of this great industry.”