AB Electronics’ goal is straightforward: Improving the productivity of clients’ businesses. How does the company do it? By providing top-notch, full-service, flexible manufacturing solutions with unrivalled responsiveness through long-term, strategic collaborations built on trust and mutually beneficial outcomes.

As a business that places a high priority on customer satisfaction, AB Electronics is dedicated to client success with its cutting-edge technology for comprehensive production solutions. From supply chain management to finished products, the company’s goal is to provide partners with unwavering quality, trustworthy on-time delivery, and best-in-class economics.

As a member of the Aragra Technologies family, AB Electronics provides its clients with the full spectrum of top-notch manufacturing services, and in order to lower costs and boost capacity, the company invests in state of the art equipment to better serve the demands of its partners.

When it comes to the various improvements and investments AB has made to embrace and utilize leading-edge capabilities, it comes down to equipment, teams, and processes. “In terms of equipment, we put in a lot of new and improved equipment, things that will automate certain parts of the process and allow the operator to focus on more critical tasks rather than, for example, just keeping the machines fed,” explains President Akash Monpara.

This includes, amongst other upgrades, putting in two new pick-and-place machines and two solder paste inspection machines to give better yield on the fine pitch placements. “At this point, we could pretty much place and assemble the most complex parts in the market,” says Monpara. “We also put in equipment that will help consistency of process.”

For example, where processes used to be dialed in with knobs, AB has added computerized and more modern equipment so the job is run the same way every single time. There is also equipment to maximize productivity per production hour by improving consistency in processes, reducing process rework, improving first pass quality, and improving quality out the door. AB has also added a number of engineers to its team to focus on process improvement and equipment integration, along with several mechanical and industrial engineers to focus on process improvements.

“We also added to our ranks a number of material handlers as we got into more traceable materials operations, which is important for the medical industry,” says Monpara. “We’re gearing up our certifications and our processes to take on more medical devices.”

These upgrades involved a lot of process trialing to achieve better consistency because better processes equals better quality, adds Monpara. Over the last two-and-a-half to three years, the company has also completed a lot of process trials, utilizing its new equipment and resources.

Along with this commitment to quality and customer satisfaction, AB is also strongly committed to taking care of its employees with a positive company culture. Along with the ownership change in 2020—which is also when Monpara joined—there was also a change in working philosophy, a readiness to invest in the team and the equipment, and a different philosophy on how to treat staff.

“We make everybody feel included and impactful toward the outcomes that they’re driving,” Monpara says. “For anyone who’s working on a product, we want them to know what it is that they’re working on, why it matters, and why it’s important that it gets done right. It gives them more satisfaction and [leads to] a good outcome.”

When the company does well, the whole team benefits, he adds. Team-building events are held at least once per quarter, whether it’s an outing at a sports bar or a golf club, or a company picnic or potluck lunch. Monpara’s team strives to conduct a lot of these events, and emphasizes that the team is really what makes the company and what makes the product. “It wouldn’t be possible without a good team,” he says.

And the team certainly appreciates everything AB does to make the working environment the best possible. “Everyone is pretty happy with the new ownership and the new environment. We’ve almost doubled since 2020, when we took over. The team is very energized about that; they feel like they’ve had a direct impact on driving that outcome and on making our customers happy. Overall, I think that’s the biggest thing; it’s not about just me as the owner of the business, but the happy customer and a happy employee. Basically, the rest takes care of itself.”

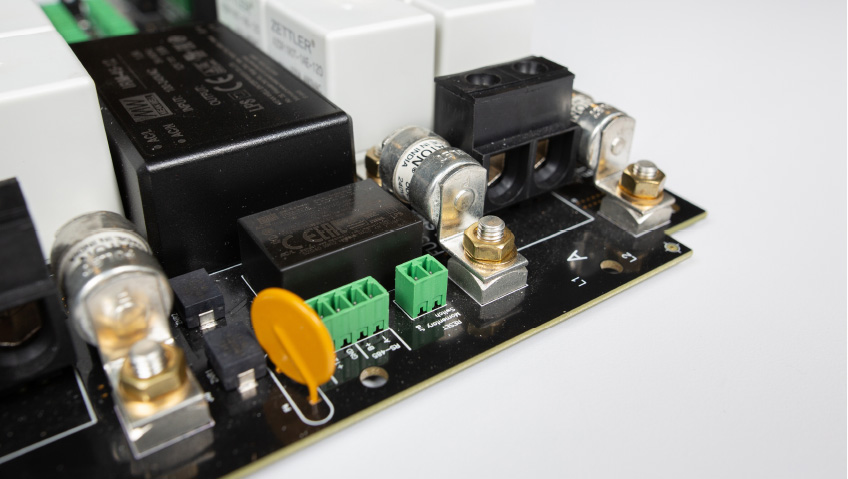

Among AB Electronics’ world-class products are printed circuit board assemblies, cable and wire harness assemblies, and box build assemblies, to name a few. AB builds the products, providing manufacturing as a service. Where it used to just build printed circuit board assemblies and cable harnesses, it now takes those and puts them onto a chassis or enclosure, building out the full product.

“It’s a lot more exciting to the team to be working on it and seeing the product come to life rather than just a component of it,” says Monpara. “And I think it’s also been something that our customers have really appreciated, because now we’re able to help them outsource more of their manufacturing processes.”

AB has also built out its testing, integration, and final assembly capabilities, taking that product one step further. Rather than just delivering a sub assembly, AB looks at how much more it can add on to give the customer more of a turnkey solution.

Certainly, AB has faced its share of challenges and also celebrated some key accomplishments over the past few years. Doubling in terms of revenue and increasing its footprint from 13,000 square feet to 21,000 square feet, along with the team growing from about 33 to about 48 today, are admirable goals that have been met.

“We’ve gotten a lot more work done proportional to the resources that we’ve invested in capital equipment, making every person that much more productive. We’ve then also been able to pay them a better wage because of the output of their time,” Monpara shares. “So investments in people and equipment have helped us grow and meet the customer needs of on-time delivery and quality.”

AB also recently became ISO 1345 certified, allowing the company to target more medical devices, and has implemented a new ERP system, which changes the way all of its business transactions are done and processed, to be more traceable and visible. But that was also one of the company’s biggest challenges due to the COVID-related semiconductor and electronics components supply chain crisis.

“Going through that challenge of not being able to get the right parts when you need them was tough. Sometimes we’re dealing with managing 200 incoming parts to make one assembly for a customer and if only one of those is delayed, then the whole build timeline is delayed,” says Monpara. “Then we’re also over-inventoried on the other 199 parts that we did get, and we can’t do anything about it until that last piece comes in.”

Simply maneuvering some of those challenges, while also changing the whole system in which the team works was a huge challenge—and a tough time to do it—but Monpara stresses that it set AB up for success moving forward.

“As we were trying to grow, customers’ demands were at an all-time high. It was hard to find people for that kind of staffing and it was a huge challenge getting the right people to be able to get the work done,” he says. “Culture shift is always a challenge.”

Looking ahead, AB aims to keep up with its success and its growth, growing with its existing customer base, and continuing on its journey to 100 percent on-time delivery and 100 percent quality, as well as targeting more medical builds, full box builds, and full product integrations. “We want to keep shaping the type of operation that we are, and our milestones are all related to that.”

When it comes to what sets AB Electronics apart from other companies in the industry, Monpara has a message that he regularly shares with his team.

“There are three guys within 10 miles that offer a similar thing, or market a similar thing as what we do, and they can probably make this for their customers, too. And if you look at just within the state, there are at least 50 of us. What sets us apart is our transparency, our integrity, and how we deal with the customer. We really make the customer’s problem our problem, and we want to be the first call that the customer makes anytime they have anything related to electronics assembly, whether it’s something in our wheelhouse or not. We want to take care of our customers and our customers’ problems.”

Ultimately, he adds, what matters most is that desire for a long-term partnership of building a two-way relationship. “Our customers’ success is our success, and our success will lead to our customers’ success,” says Monpara.

Just having that mindset as a core driver of the company’s whole operating philosophy is what truly sets anyone apart in this industry, he adds: How well do you take care of your customer and your customers’ problems?

“It’s all about the customer, and how we approach getting a good quality product delivered on time is pretty much the whole story of what we do,” Monpara says. “It’s a very competitive industry. But we want people to see that it’s easy and a pleasure to work with AB.”