Recently, we had the pleasure of speaking with Matt Uecker, Sales and Marketing Manager, and learning that what goes on inside Cincinnati Gasket and Industrial Glass’ 65,000-square-foot manufacturing facility is crucial to the continued functioning of just about every major industry, from steel and chemical industries to machine tool, power generation, and biotech laboratories.

Uecker was brought on board eight years ago by third-generation company owner, Larry Uhlenbrock, who he describes as a “terrific guy and very generous to employees,” many of whom have worked for the company for over 25 years.

“I’m still a newbie here,” he says with a laugh. Nevertheless, he brings to the company the considerable expertise and experience acquired over a 30-year career in mechanical engineering.

“One of my early jobs was as a maintenance supervisor at an automotive assembly plant and that was a highly educational experience, not only from a personnel management stance but also from a technical standpoint, because there were over 100 machines that I was responsible for keeping running. I had to know a little bit about a lot of things, but I also learned to rely on skilled trades who have in-depth knowledge.”

This experience gives Uecker insight into the issues that his customers—industry maintenance planners responsible for the spare parts needed to keep equipment operational—must deal with. He and his team of experienced inside and outside sales associates interface directly with all their industry customers to make sure they have what they need on hand, ensuring that plants never have to be shut down while waiting for parts to arrive.

It started with a gasket

The roots of the Cincinnati Gasket and Industrial Glass Company, originally only a gasket manufacturing company, go back to 1907 when Cincinnati, Ohio was coming into its own as one of the premier machine tool manufacturing centers in the world.

As Uecker explains, gaskets are essential for machine tool manufacturers as well as every other major industry that involves liquids, gases, or steam flowing through pipes or vessels that need to be securely sealed. Because Cincinnati was in the heartland of industrialized America, it was an ideal location to establish a large gasket shop that could not only serve the needs of OEMs, who install them into equipment such as industrial compressors, but also of the maintenance, repair, and operations departments of industrial plants.

“We are considered a job shop and make individual batches of gaskets to order, in any size, shape, configuration, or quantity, from literally over 150 different materials,” Uecker says, noting that the company also supplies regular ANSI (American National Standard Institute) sizes that are used in pipe fitting applications. Approximately one-third of the 65,000-square-foot facility is occupied by the gasket shop, which uses manual presses for very small runs and automatic machines that can produce up to 1,000 gaskets per hour.

In the early years, the gasket company’s market was largely regional, but with the addition of industrial glass, particularly heat shield window systems, to its offerings, Cincinnati Gasket and Industrial Glass became the largest such company in the Midwest and now ships products around the world.

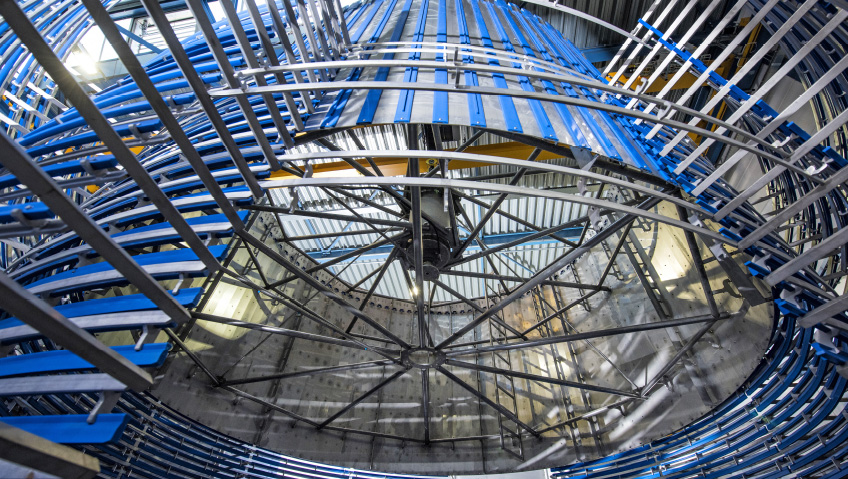

The remaining two-thirds of the facility is occupied by the industrial glass side of the business and includes TIG (tungsten inert gas) welding equipment and two 10-foot-long water-jet tables with state-of-the-art CNC cutting machines that efficiently cut round and non-linear glass and steel pieces.

“You can cut a lot of glass on a 10-foot water table,” Uecker says. “We can put two of our standard borosilicate sheets on there at a time.”

Seeing clearly

According to Uecker, it was the gasket business that led to the company’s expansion into the industrial glass business in the middle of the 20th century.

At the time, companies were buying gaskets for their maintenance and repair departments, but for certain applications needed to purchase industrial sight glass from a third party and have that installed between two gaskets so the interior of pipes, vessels, or furnaces could be monitored. Requests to purchase the gaskets and sight glass together in a single package from the same company “are what pulled us into the glass business, which has evolved incredibly from those days until the present,” Uecker explains.

Industrial—or borosilicate—glass, he tells us, is created by the addition of boron to the mix of silica sand, soda, and lime which is used to manufacture standard window glass. The benefit of borosilicate glass is that it has a very low CTE (Coefficient of Thermal Expansion), meaning that it expands and contracts very little when heated or cooled so it won’t shatter with sharp temperature changes, like standard glass.

This glass is used by the company to produce anything from tiny pieces of glass that might go into after-market carburetors in high-performance engines, to large heat-shield windows and protective window systems for cranes, pulpits, or mobile equipment in steel mills, where they’re close to large vessels filled with white-hot molten steel or slag.

The company also produces synthetic or fused quartz glass parts for various applications such as lenses for UV curing lamps and for sight windows that need to withstand extremely high heat and chemical applications. According to the company, it has high chemical resistance, good thermal shock resistance, and a low thermal expansion coefficient. Since quartz glass transmits ultraviolet light well, it’s useful for lenses and optics for the ultraviolet spectrum and ideal for precision mirror substrates.

Heat shield glass

Uecker says his favorite aspect of the business may be the heat shield sector. Besides providing increased heat and blast protection for operators, these window systems, featuring steel or extruded aluminum frames and intended for heavy industry, are designed so that if one or more layers of glass does break, it can be quickly changed by in-house maintenance personnel with minimal downtime.

The quick-change window systems have been well received by a variety of industries, not only because of the ease of replacement but for the protection of mobile equipment operators, such as crane operators that operate in close proximity to electric arc furnaces, blast furnaces, BOFs, and similar hot, hazardous environments. A wet charge in a furnace will cause a minor explosion which could result in a blast of heat and material splattering out with some force, creating a potentially life-threatening hazard to the operator. Not only does the company’s window system provide vastly superior protection, it can be replaced quickly—unlike OEM windows, for which such an event renders the crane inoperable until a contract glazier can be brought in to replace the glass.

But with a window system from Cincinnati Gasket & Industrial Glass, a new one can be installed in a matter of minutes, eliminating the majority of the downtime.

The company thus has a long-standing relationship with the steel and slag industries where equipment operators, the people running the front-end loaders, cranes, and furnaces, must be protected from the hazardous materials they handle in tough conditions. But now, a variety of other industries that don’t handle such dangerous materials are looking to use these window systems too, owing to their ease of replacement.

Looking ahead

Uecker shares that offshore manufacturing has hurt the business as it has so many others, shrinking its customer base over the years. The advent of LED lighting, which generates so much less heat than incandescent lighting, has also reduced the need for glass, with that industry now almost exclusively using plastic. But, he says, sometimes when one thing is taken away, another opportunity comes along, and now the company’s semiconductor business has grown due to an increased demand for borosilicate glass used in the manufacture of various chips.

Most of all, Uecker is encouraged by positive industry change which focuses on safety, and how the heat shield window systems have become an integral part of that. “That’s a big focus of my energy now,” he says, “to help those industries put our style of protective window systems into their equipment and keep their people safe.”

He recalls how, in the 1950s, it wasn’t unusual to have dozens of people killed in a year in the steel mills of Cleveland and Pittsburgh, unthinkable in the context of a mature industry and the changed attitudes of today. Now it is the companies themselves who are the drivers behind higher safety standards, who want their employees to have the best equipment to work with.

“When I started in the steel industry in 1987, they were pretty safety-conscious, but today I would say they are 100 percent more safety-conscious than they were then,” says Uecker. “The prioritization of safety has increased exponentially over the last several decades and that is a very good thing.”