Phillips Corporation has been solving manufacturing challenges for the United States government, industry, and education leaders for over half a century. The Hanover, Maryland-based business has grown to become a global presence over the decades, building strategic partnerships with technology leaders such as Haas Automation and EOS.

As an industry leader, the company was already working in 3D printing 25 years ago, then picked up additional additive manufacturing lines, growing the business into what it is today by providing a full suite of solutions. “We cover just about every additive technology out there,” says Brian Kristaponis, General Manager, Hybrid Division. “So we really have a full portfolio of offerings for our customers.”

And that’s not all; the company also offers robust support to ensure that customers are well taken care of after the purchase is made. “[We have] the applications engineers and service teams to support those machines that we sell,” says Kristaponis.

This capability to fully support the customer stands out in the industry. “I think our applications team is really what sets us apart. With our applications team, we’re not just focused on training customers how to actually use the machine, but we have experts that are end users as well. So we’re able to take customer parts and develop their applications in-house on our machines, as well as providing full turnkey solutions for these systems. And that covers both additive and subtractive processes. A lot of companies may specialize in one, where at Phillips, we have experts in both additive and subtractive manufacturing.”

Phillips Corporation has a Federal Division, Commercial Division, and a new Hybrid Division, introduced just last year when the team identified a gap in the market. “We had an opportunity with Autodesk to sell them a hybrid machine,” Kristaponis remembers. “However, we didn’t have a hybrid solution at the time. So through a partnership with Phillips and Autodesk we were looking for vendors for this welding technology and we discovered Meltio. We built the first machine for our first Phillips hybrid for Autodesk with the Meltio welding technology. And then from that point, we saw an interest from the U.S. Department of Defense to create additional Haas hybrids using Meltio system with wire technology.”

After the launch’s initial success with Autodesk and the U.S. DoD, the team began to take the next steps. “We really focused on making this a commercial product in 2022,” Kristaponis says. “And that was really the initial start of our Hybrid Division.”

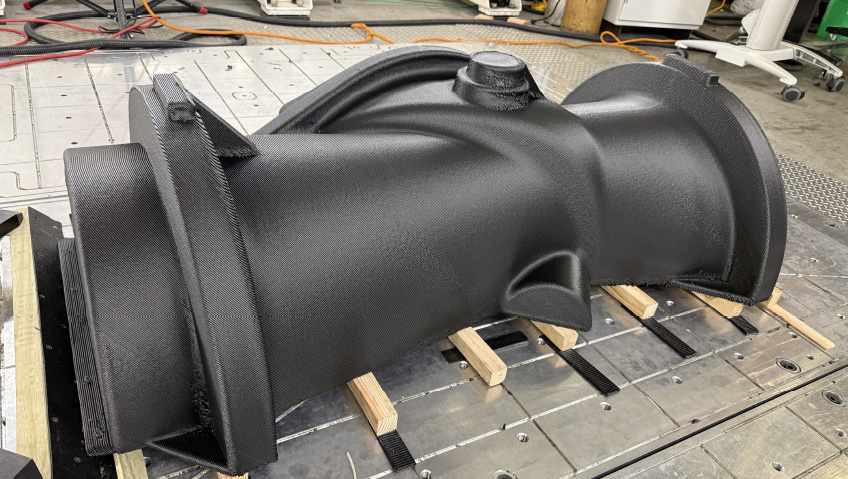

The Phillips Additive Hybrid powered by Haas combines the advantages of traditional CNC machines with the benefits of additive technology. “We’re talking about subtractive machines and additive machines all being on the same platform,” Kristaponis explains. The solution draws on a strong foundation built on a 30-year relationship with Haas Automation, which has led to more than 30,000 Haas machines installed worldwide. “Our conventional kind of offering on the subtractive side has been Haas machines,” he says. “We’ve often sold standalone additive products,” and now, the company’s new hybrid solution brings customers the best of both worlds. “We’re using the subtractive side of Haas and the additive side of Meltio.”

Learning to use this next-generation technology may seem daunting, but hybrid solutions are much easier to adopt than often assumed. In fact, the Hybrid Division focuses “on the ease of use of our system. When we show this technology or people see videos of the machines running online, it’s very intimidating. And I think that’s one misconception; when we talk about hybrid manufacturing, it doesn’t have to be difficult. These machines are programmed just like any other CNC machine. And I think having somebody come see the machine, see how it’s programmed, would be very reassuring that it’s not some brand-new technology. We’re building on the existing things that they know, so hybrid manufacturing really isn’t this brand new idea. We’re utilizing what existing manufacturing facilities are already using.”

The company funnels plenty of resources into customer support, ensuring its engineers are always available to lend a hand. “Our numbers right now are probably in the 40 to 50 range, of application engineers at Phillips,” Kristaponis says. “The value [we provide] comes in that support and being able to show customers how they can be competitive in today’s manufacturing markets. So when we talk about our applications team, it’s really developing those parts for customers and using their machines to their full capability.”

To help customers reach their full potential, the Phillips team is committed to educating and inspiring the entire industry to best utilize additive manufacturing. “We have training curricula that we’ve developed for our hybrid machines,” Kristaponis says. “We support our customers with initial machine training as well as continuous phone and video support to make them successful with our machines, and that’s really what it’s all about. We may sell machines, [but] that’s really the small portion of our business. It’s making customers successful in actually using the systems for real end applications. So we’re not trying to print parts just to print parts; it’s finding those applications that make total sense and building case studies and showing the customer the value of these processes that we’ve developed.”

Partnering closely with technology leaders is important to the company, and these relationships extend far beyond the standard OEM relationship. “It’s not just our OEM relationships that we have, but it’s also the different technical institutions that we have relationships with.” For instance, the company works closely with the Institute for Advanced Learning and Research [IALR] and Danville Community College. “When we talk about IALR or Danville, not only have we partnered with them, but we have innovation centers there,” Kristaponis says. “We also have a lot of different universities where we not only have machines, but we give them our curriculum to help train their students. Obviously, we have great relationships with our OEMs and can leverage support from them when needed, but we also partner with a lot of different technical institutions in our territory.”

Looking ahead, the team is eager to continue to grow and strengthen its Hybrid Division, and to keep spreading the word about its benefits. “Our biggest goal is making the easiest to use hybrid on the market, as well as showing customers how they can be competitive with this technology and what this technology offers,” Kristaponis shares. “In the next year, you’re going to be seeing a lot more case studies out of our group from the Hybrid Division, really highlighting how these applications [benefit the industry]. That’s a lot of the work that we’re doing right now.”

And this is only the beginning. “As a company, we’re always looking for the newest technology on the market,” Kristaponis says. “With Meltio, we really believe that what they’re developing with new systems coming forward in 2024 will definitely be the latest and greatest additive technology we can offer.”

Always eager to embrace the latest developments to create the best, most innovative solution for the customer, Phillips Corporation will be one to watch in the coming years as the team focuses on providing the very latest, market-leading technology.