Since its founding in 1980, Eberle Design, Inc. (EDI) has earned a formidable reputation as a global developer and producer of high-performance component products that improve and supplement traffic management systems. With the EDI product lineup, transportation experts can integrate, automate, and manage traffic at signalized intersections and on highways with greater effectiveness and safety.

Regarded as the benchmark for traffic control systems and the established market leader across the board, EDI’s forte is dependable high-tech traffic cabinet components, signal monitors, vehicle detectors, power supplies, load switches, flashers, bus and serial interface units, and Advanced Transportation Controller Cabinet (ATCC) components for traffic control.

The benefits of the EDI lineup include more than 43 years of electronic engineering, standards leadership, product innovation, and equipment with pre-installed setup and diagnostic tools that allow accurate installation and troubleshooting, invariably saving time and money overall.

Overcoming the odds

Despite the company’s remarkable success, the past few years threw up several extreme challenges to be met, particularly by way of a pandemic that disrupted supply chains around the globe for almost every industry.

“We couldn’t point to one agent, company, or industry. It was the whole world that fell apart,” says President John Shearer. “But we were all trying to solve the problem together. EDI is critical infrastructure, though, because we make products for signalized intersections, and if we don’t make products, traffic lights go dark and vehicles can’t get around.”

As EDI services approximately 380,000 of the 400,000 intersections in the U.S. and Canada, Shearer’s remark can be taken absolutely literally. So the company’s doors remained open full-time, with its Phoenix, Arizona-based manufacturing plant working 40 hours a week to build those essential products and keep communications open with its vendors.

“We were able to talk to our vendors and say, ‘we need these parts,’” says Shearer. “We realize in the open component market we’re competing against everybody who needs a resistor or a diode with a certain specification, including companies like the Ford Motor Company, but if they don’t sell any cars for six months, it’s not the end of the world; if we don’t sell any components, and traffic signals go dark, it’s critical.”

While EDI isn’t a billion-dollar Fortune 500 company, it was able to negotiate persuasively with its vendors for products that were crucial to the economy of the whole of North America.

“It was about communication and transparency to make sure the supply chain is robust,” says Shearer. “If we needed a million components but they could get us 100,000 for the month, that would keep things going. So there became allocation and prioritization of raw components.”

Building collaboration

The process required collaborative problem-solving and actively engaging with businesses to identify alternative solutions or workarounds. The company employed its expertise and experience to explore options like sourcing materials from different locations, adjusting production schedules, and finding alternative suppliers.

“Luckily, we have an internal purchasing procurement team that’s highly skilled and experienced,” Shearer says. “Our vendors supported us whenever we would reach out to alternative vendors, adjusting lead times and partial shipments.”

“We did a lot of broker buys and a lot of finding components that were in storage somewhere, putting them on a jet plane, and bringing them in at a significant cost increase,” Shearer says. “We had one integrated circuit that went from $1.70 to $70 going into a product that would sell for $100.”

While this led to some surcharge pricing on specific components, vendors demonstrated flexibility by being willing to adjust lead times, provide partial shipments, or offer alternative products that met specific requirements, enabling businesses to maintain operations and serve customers to the best of their abilities. “Adjusting our production schedule was critical and we did a lot of that through vendor support, finding alternatives… and then we would adjust to that new supply chain timeline.”

While the situation is better now, it’s not yet perfect, with some components still in short supply that EDI pays a premium on.

Analyzing risk is, of course, imperative along with remaining proactive about it, including implementing robust risk management strategies such as building buffer inventory, diversifying the supplier base, and investing in redundancy to minimize disruptions and ensure a more reliable supply. “We didn’t shut our doors and our customers didn’t have to turn off their signal lights. So it worked out well.”

Navigating the times

While vendor support during these times was essential, it came down to relationships, says Shearer, with both parties working together to find solutions and minimize the impact on business operations. By maintaining strong relationships and effective communication, businesses and vendors navigated challenging times and emerged even more resilient than before.

“We were all in this together,” he says. “If we can’t build products, we can’t buy their raw materials, they don’t sell, so it backs up. You have to work to find solutions and mitigate problems. Having strong relationships with your vendors was really important, and the communication was huge.”

COVID, of course, played havoc not only on the day-to-day business; keeping doors open during the pandemic also meant a major drive to keep employees safe throughout.

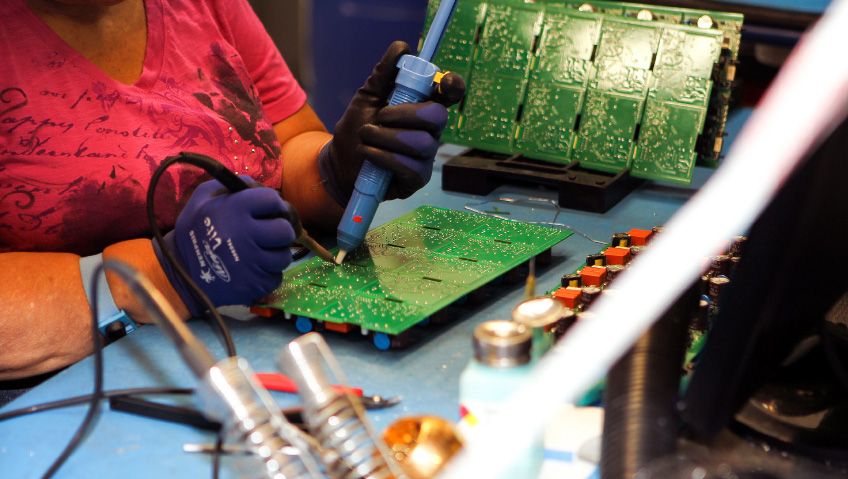

“In the early days of COVID, no one really knew how serious and how contagious it was, so there was a lot of fear,” says Shearer. “We immediately started developing health and safety protocols. While salespeople, accountants, and others could work outside the office, we had approximately 100 people in the shop who had to come in every day, because they had to place components on circuit boards, they had to solder. It couldn’t be done at home.”

EDI put up partitions, ensured everybody had plenty of cleaning stations, enforced mask-wearing, and gave liberal time off to anyone who was sick. “We focused every day on safety and health for our employees as well as compliance with government issues,” Shearer says.

Along with physical worries came mental health concerns such as anxiety and stress. EDI took on a much more focused and granular approach toward safety and mental health for its employees to ensure they had the support they needed.

“We asked employees how they were feeling—not just sick but whether they were anxious or scared,” Shearer says. “It was the right thing to do. We value our employees. We wouldn’t be in business if we didn’t have 165 great people coming in every day and giving all their efforts. We wanted to make sure we were giving back to them by giving them a safe work environment above and beyond what we normally do.”

EDI also communicated to its end users, keeping them up to date weekly, sending out letters explaining any supply chain issues and which products would or wouldn’t be available for another six months, along with alternatives.

“We would even help people find other solutions that we didn’t sell ourselves,” says Shearer. “We were profitable, but we also lost revenue and profit with supply chain cost escalation, and we couldn’t always raise prices. But the financial commitment from management at the top never wavered. We were proactive in taking care of our end users and our supply chain and everybody in between.”

Lessons learned

EDI is not only extremely well known in the industry, it plays a vital part in the overall transportation infrastructure. In such a dynamic arena, the company has continuously evolved. The team has made changes including shifting to online platforms and engaging with the digital market; enhancing safety measures to instill confidence among customers; prioritizing customer experience by improving communication channels; addressing customer concerns promptly; and personalizing experiences whenever possible.

Further steps are supporting remote work and virtual collaboration and adopting innovative approaches such as exploring new revenue streams, partnerships, and business models.

“Optimizing our customer communications tempo was the biggest shift in driving value through our system and prioritizing customers’ experience,” Shearer explains. “We learn more about what’s critical to our customers because we talk to them daily. We also drive extra value by communicating proactively with all of our suppliers up and down the chain.”

Emerging into the future

The company has experienced a number of changes in its 43 years. It was founded in 1980 by Terry Eberle, who in 2010 sold it to private equity. From 2010 to 2022, EDI was owned by five different companies, one strategic and the other four private equity.

“None of them, except for the most recent, invested in our future,” says Shearer, singling out current owner Vance Street Capital. “It truly is a partnership. They’re always available. They’re always helping us and we’re very excited about where EDI goes over the next five to 10 years. They’re investing in us through leadership and guidance, and we’re hiring people, growing our capabilities, buying machinery, and doing a lot of things previous owners didn’t see as priorities. Our future is extremely bright,” he says.

As the world was thrown into upheaval in the past few years, businesses had many decisions to make affecting both the present and future, and EDI has made a lot of positive ones.

“When the pandemic kicked off, I think the entire world was in survival mode,” Shearer says. “You do what you can, you control what you can, and you try to adapt to what you can’t control. From that, you learn a tremendous amount about the world, the economy, your customers, supply chains, and your own business. And then you don’t forget what you learned,” he shares.

“We’ve really made the best of it, but at the same time, it’s actually made us a better, stronger company.”