For more than 25 years, EDSI Inc. has produced essential parts for robotic systems used in painting, sealing, welding, and material handling applications, harnessing its impressive experience and expertise for the development and design of these systems.

Whether it’s EDSI providing AutoCAD and E-Plan CAD design support or distributing SMC Pneumatics components and assemblies, customers benefit from the company’s years of building knowledge and proficiency in the best methods and systems for producing control panels, pneumatic control panels, and tag engraving, driven by skilled and talented staff.

With the company’s hardware engineering and design currently housed in a 33,000-square-foot facility, EDSI’s customers reap the benefits of cost-conscious discipline without compromise in quality, whether in the electrical, mechanical, or pneumatic aspects.

Servicing the automotive, industrial, robotic, aerospace, military, and medical industries, EDSI’s broad range of electric automation and pneumatic equipment across various industry segments has helped it become a global leader in the industry.

Formed on September 18, 1997, the company started out as System Technology, Incorporated with different ownership, before moving to a new partnership and a new deal.

Design at the core

“We started then as just a design place,” explains President Rock Haas. “My current partner came on in the following year in 1998, and that’s when we started building control panels.” This change allowed the company to expand into performing both design and control panel builds.

“We found our little niche market,” Haas says, “and we expanded it a couple of times and went with more space. And then somewhere along the line, we started building pneumatic panels.”

EDSI then became an SMC pneumatics distributor, followed by moving into building robotic training carts, he adds. “All of those areas have gotten very, very large,” Haas says.

The company provides a number of services, such as building valve manifolds, FRL assemblies, and pneumatic panels, and offers custom pneumatic design complete with the pneumatic print package.

As an SMC Pneumatic Premier distributor, EDSI also supplies an impressively wide range of products including actuators, directional control valves, airline equipment, connectors, vacuum products, industrial communication products, sensors and switches, static control products, electric actuators, chillers, and dryers, all of which can be sold individually or in custom assemblies.

Solutions across industry

“We have a design team that can take a customer’s ideas and transform them into custom, fully-tested, plug-and-play solutions,” says Mike Weiss, Senior Key Account Manager. “We do work for the largest automotive manufacturers, the world’s largest robotic companies, and all tier suppliers to the automotive industries.”

Outside of the automotive industry, the company also supplies the aerospace, food and beverage, packaging, pharmaceutical, medical, cleanroom, car wash, and process control industries, all with an eye to maintaining superior craftsmanship.

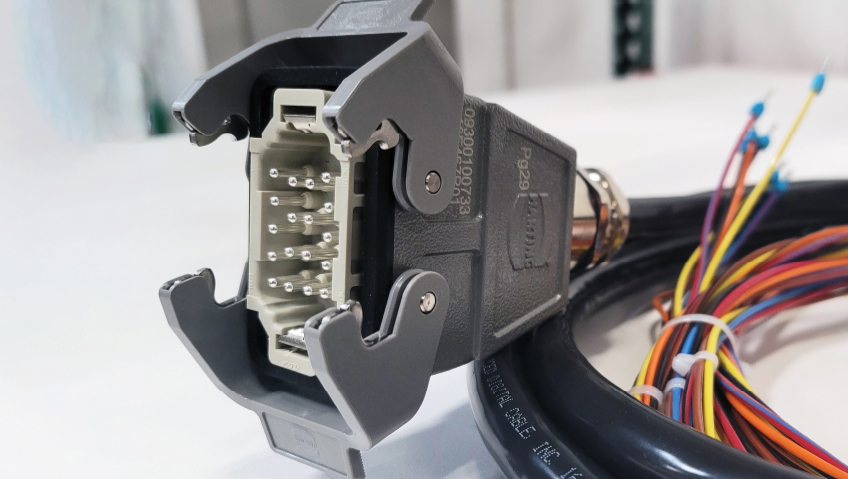

Another recent, successful product addition is EDSI Cables, which started last year and allows the company to provide custom cable specialty harness assemblies and custom designed interconnect solutions.

“The addition of our own custom cable shop has helped our customers maintain target delivery dates amid a global supply shortage,” says Weiss. “We’re able to cross our customers’ components—cable bulk and connectors—to in-stock items.”

From its more humble beginnings as a panel-build shop 25 years ago, EDSI has attained a worldwide status making and supplying custom control panels across a wide range of industries, while striving to provide top-notch service from start to finish.

“In the industry, our craftsmanship and quality are second to none,” says Weiss. “This has helped us land and maintain some key accounts for some of the world’s largest manufacturers.”

Powering people

This dedication to quality encompasses everything EDSI does. With its staff, it’s a commitment to keeping the same qualified and motivated people in place the entire time, Haas adds. On the rare occasion that anything goes awry, it is that staff that ensures clients remain fully satisfied.

“When that happens, they’re very good at making things right,” Haas says. “The funnel to the door has been the same since the beginning, with the same people. Because of that, not much slips out.”

The company’s decades of successful devotion to exceptional quality are also due in part to its quality department, which is very strong, Haas says.

EDSI’s full-service machine shop is also a source of pride to the company, manufacturing, modifying, and repairing parts for a wide variety of clients. It boasts highly skilled fabricators and machinists who enable EDSI to consistently meet customer needs most cost-effectively and accurately.

“We don’t advertise or sell this service to customers, but with the machine shop we’re able to keep our business going,” Weiss says. “We’re able to make several specialty pieces for our assemblies in-house. These services allow us to control inventory, costs, and lead times for critical brackets, plates, and custom adaptors.”

Crossing components to in-stock replacement parts is one of the many strengths of EDSI. “We have a team made up of people who are very knowledgeable in the industry and we can find in-stock parts that work for our customers’ applications,” adds Weiss.

The company is always ready to apply its extensive experience and skills in diverse and unique ways. “In the spring, we were asked by the U.S. government to help with the relief efforts in Ukraine,” says Weiss. “We were able to help by 3D printing tourniquets that were sent to Ukraine.”

Challenging the challenges

Of course, all companies experience their share of challenges, and Haas cites the year 2009 as being a particularly difficult one for all businesses across the board. “You know, everybody went out of business, and we didn’t, so we’re pretty proud of that,” he says. “We managed to survive through a rough time.”

Lasting 25 years is an accomplishment all on its own, but a more recent point of pride is EDSI’s current “gigantic” backlog. But, Haas adds, an ongoing shortage of available, qualified labor has made getting through that backlog extremely difficult.

Growth is a good thing for any business but has its challenges, something EDSI is experiencing firsthand. “Currently we’re in 33,000 square feet and it’s getting embarrassing,” Haas laughs. “We can’t walk around much. Every area of our business is tight… We need more space. So we’ve purchased a much larger, 75,000 square foot building that we can move into and have a little more space.”

Housing a department that builds control panels, a department that builds cables, a department that builds training carts, a department that builds robot controllers, and an area that builds pneumatic assemblies, EDSI has simply outgrown its facility.

“All those areas need to be bigger,” he says. “It’s a good problem to have.”

Along with this looming substantial change, the company has several milestones coming up. “There are some sales milestones, obviously,” says Haas. “We have a sales team that’s trying to get business outside of our normal channels, which are robotic paint, sealing, welding, and mobile training carts for high schools and colleges. Those are our normal channels. But we also own a company called EDSI Cables that builds custom control cables and robotic cables. I hope to push that to the same level as EDSI.”

The opportunities are there, Haas adds, prompting a decision to get another sales team and push some of the areas where the company has room to expand. This includes doing more EDSI cables and pneumatics, of which the company currently has several million in stock.

From the top

While the technical staff, sales team, and clients all combine to make EDSI special, when Haas is asked what sets the company apart from similar competing companies, he has the answer ready: “The quality of our product and the people who produce it; our staff have been with us a long time and are dedicated to the goal of producing a quality piece that is second to none in our industry. This dedication has gotten EDSI to where we are today and is the reason we are expanding and growing at the pace we are today!”

A new year usually brings with it resolutions for change, and while EDSI’s growth means changing to a new working space, its commitment over the years to maintaining quality product and people remains steadfast.

“We try to do the right thing and make quality the first thing, and it’s worked out well for us,” says Haas. “Like I said, 25 years and still growing. That’s impressive.”