Gravotech is built upon a rich history of engraving. The company’s story began in 1938, in New York City under the name New Hermes, when a small team began producing advanced pantographs that enabled typographic consistencies within dies. A merger with French company Gravograph several years later launched a series of joint ventures, setting the business on a path to eventually become the international leader in permanent markings.

The acquisition of Technifor and Vision Numeric in the early 2000s solidified Gravotech’s place as a global leader in the identification markets, offering a complete suite of engraving and traceability solutions.

Today, Gravotech boasts a presence in 18 different countries through its subsidiaries and serves customers in more than 70 countries. The company’s collaborators speak 35 different languages each day to deliver services to over 200,000 users. “A vast global footprint of learned and shared knowledge spanning 95 years, built from various applications, keeps Gravotech the industry leader in its fields,” says Business Manager Don Kirch.

Gravotech’s global headquarters is located in Lyon, in the south of France. The company also has three main regional manufacturing hubs in Atlanta, Shanghai, and Troyes, a city strategically located close to Paris. From these locations, the company manufactures laser hardware, including galvo and gantry, rotary CNC engraving machines, dot peen and scribing machines, plastic laminates for indoor and outdoor signage, labels, control panels, serial plates, and accessories. The company also owns and develops software specifically designed for engraving, cutting, traceability, and 3D mold and die making, enabling Gravotech to deliver a complete suite of solutions for multiple sectors and needs.

“Gravotech has become a comprehensive yet nimble force, servicing various industries with limitless applications,” says Kirch. This wide service range includes the automotive and aerospace markets, industrial control panels, machine original equipment manufacturers (OEMs), electrical panels, part marking, serial plates and signage, jewelry, gifts, sporting goods, awards recognition, and luxury brands.

Traceability has become increasingly important, and Gravotech is able to meet that need. “In line with the digital transformation of industrial manufacturing, the permanent marking of parts is essential today so that they can be identified and traced in the production flow and throughout their life cycle,” Kirch says. “As the inventor of dot peen marking in 1985, Gravotech is historically known as the world’s leading manufacturer of permanent dot peen marks, scribing and laser marking machines for the traceability and identification of industrial parts within various materials, [including] metals, plastics, and other organic elements,” he shares.

“Since the dot peen marking technology invention 40 years ago, Gravotech has continued to innovate, and its XF510p pneumatic dot peen marking machine takes the crown for being the smallest and fastest on the market, all while meeting high standards of precision.”

The remarkably compact XF510p is ideal for restricted spaces. “The integration is made simple, in any position or direction, reducing the overall time and cost of installation,” Kirch says. “With a marking speed of 12 characters per second, its effectiveness sets new standards for speed while being able to work uninterrupted on production lines,” he explains.

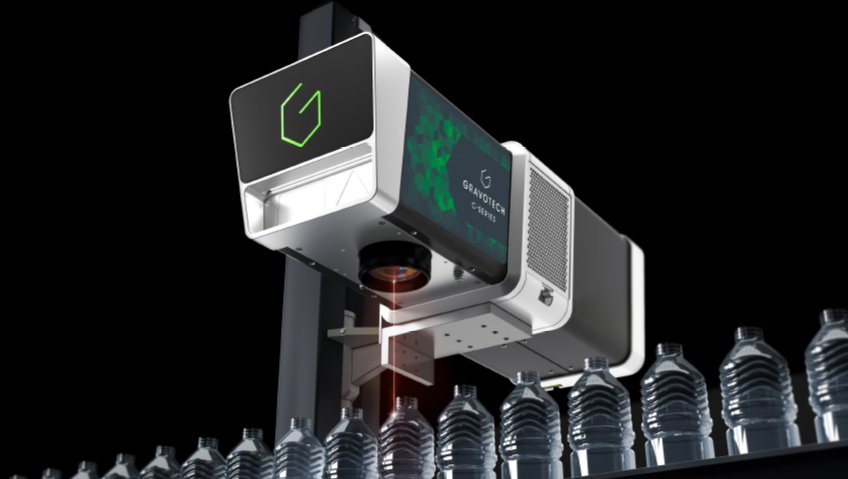

“Our powerful and high-quality industrial laser engravers perform extremely accurate and defined markings fast and efficiently,” Kirch continues. “Compact, with great input communication links and simple to integrate into a manufacturing process, this heavy-duty design, based on a cast aluminum structure, [has] high-quality optical components, guaranteed strength, and minimal maintenance. Whether integrated in a production line or as a robotic cell, the integrated laser implementation is easy in any mounting position and can be oriented toward the part surface to significantly reduce installation setting times and overall tooling costs.”

Gravotech offers retail engraving through mobile designers and websites, fulfillment centers, and retail stores. The goal is “to make the customer personalization experience an efficient yet memorable one,” Kirch says. The process “makes for an easy and fun” shopping experience, “while expanding the retailer’s product line offering with unique engraving-personalization, only limited to the customer’s imagination, without expanding inventory or shelf space.”

Machine customization and easy-to-use software makes Gravotech’s retail personalization possible. After the customer enters an order via a mobile phone, kiosk or website, then it goes to the cloud. A scan of the bar code (created automatically when the consumer enters their order) pulls the corresponding message into the machine, to be engraved on the product, saving a “tremendous” amount on “overhead, job layout, job creation, training costs, mistakes, scrap, order entry, production processing times and more, while improving the customer interactive experience and offering choices of in-store pick-up or home delivery,” says Kirch. Robotic integrations are also available for even further overhead savings.

For industrial purposes, Gravotech’s CNC engravers can engrave and cut a range of materials including tool steel for dies, stainless steel for elevator panels, and wood, urethane, and plastics for signs, fixtures, and fabricated components. Galvo and gantry lasers are a popular choice for production engraving, cutting, and traceability marking applications. “Lasers excel in applying detailed logos, text, serialization, linear barcodes, UID, data matrix and QR codes with embedded information to include serial and lot numbers, drawing or job numbers, and security codes needed for traceability, life cycle, or OEM component identification,” Kirch explains. “The wide range of laser technologies offered by Gravotech gives you the ability to polish, anneal, mark, etch, texturize, ablate, or cut a wide range of materials with very high precision.”

Hybrid and fiber lasers are ideal for metal marking, in addition to removing the metal surface or cutting through metal for fabrication. Green lasers or ‘cold marking’ lasers apply high contrast marks on high quality finished plastics and precious metals without the risk of heat damage. CO2 lasers work well for cutting, engraving, and decorating a variety of materials and popular retail products. “With output power up to 150 watts, CO2 lasers can cut one inch thick acrylic in a single pass, resulting in a flame polished edge, and yet have the control to only release enough power to apply a high-resolution photograph onto the surface of paper or painted metal,” Kirch describes.

The company also manufactures and distributes a full range of engraving materials and accessories for indoor and outdoor applications in matte, satin, glossy, and textured finishes. Flame-resistant, temperature-resistant, and chemical-resistant materials are available. And, in addition to standard formats, the company provides custom colors, sizes, shapes, and more.

All Gravotech materials are of the highest quality. Raw materials are 100 percent prime, meaning only virgin materials are used, with no regrinds. Cap consistency is maintained by extruding the cap and core separately, then laminating the layers together after each layer has cooled and solidified, rather than using the cheaper coextrusion method. Color consistency is also carefully maintained, as is sheet flatness. By using an in-line extrusion process, the material is never rolled, eliminating any tendency to curl.

Indeed, not all consumers are aware of just how important it is to use quality materials. “Gravotech understands color and cap consistency as very important traits,” Kirch says. Without this detail focus in material manufacturing, re-running a job becomes a risk, because halfway through completion, the cut didn’t reach all the way through the cap and provide a consistent, brilliant color change. It can be especially frustrating after a large matrixed job runs for over an hour. Engraving deeper to compensate can add wear to cutters, reduce productivity, and ‘bleed’ characters together, creating poor quality finished product.

Producing a better product is what Gravotech does best—and has been doing for nearly a century. With a long history of success and an enduring commitment to quality, the company has positioned itself to remain at the head of the pack for many more decades to come. “Both in-house and along with technology-leading partners, Gravotech has continued to innovate and invest into the future,” says Kirch.