Established in 2004 as a CNC business with just one machine, San Diego-based 5th Axis Inc. has enjoyed steady success over the years, now working with more than 100 three-, four-, and five-axis machines, producing a wide variety of parts for a range of sectors, all while withstanding difficult and ever-changing production problems.

Through innovation and years of research with some of the best engineering and machining talent on the planet, the company has created manufacturing techniques and proprietary tooling systems that are unique in their efficiency, competitiveness, and cost-effectiveness.

An engineering, design, and manufacturing company with a focus on aerospace, healthcare, and defense sectors, 5th Axis has a team of experienced engineers and machinists whose remit is to better customer expectations with creative, profit-improving solutions.

Committed to reshoring strategies, 5th Axis also proudly sources American companies to aid in the revival of American manufacturing.

Going 5-Axis

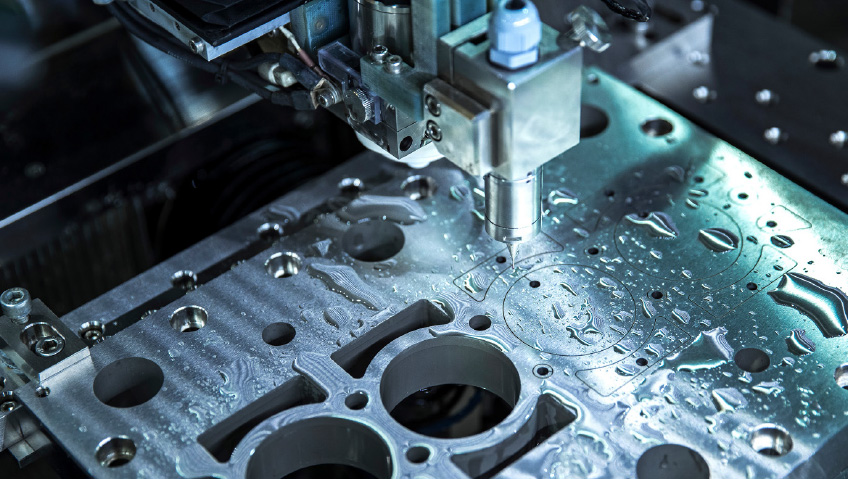

Boasting numerous advantages including a single setup, as opposed to multiple preparations necessary for 3-axis machines which could lead to inaccurate alignments and extra costs, 5-axis CNC machining simplifies the production of complex forms, which increases productivity, saves time, lowers costs, and eliminates operator error.

This procedure not only allows the machining of complex parts that would otherwise need to be cast, but also eliminates wait months for the casting to be completed if only a few prototypes or small runs of parts are needed. These advantages have led many industries to embrace this production method—but it’s one that 5th Axis has focused its formidable abilities on perfecting.

“5th Axis products are built for machinist by machinists,” says Aaron Huber, Marketing Manager.

Founded by Chris Taylor and Steve Grangetto, two mechanical engineers and friends who worked for a large company with a basically outdated machine shop, the duo recognized that 5-axis machining was the wave not only of the future, but the industry. The challenge was all the spark their entrepreneurial spirit needed, bringing to life their vision of increasing machining efficiency and creating a forum to dream up and design unique ideas.

“After six years of operating a successful machine shop for the aerospace, medical, and military industries, they realized there was a lack of well-designed work holding to accommodate the 5-axis machines’ usually smaller work envelopes,” Huber says.

“The duo collaborated with their talented machinists and programmers to design robust, compact and precise work holding to further increase efficiency and maintain competitiveness.”

This is when the “lightbulb flashed on” and their original dream of invention was resurrected, he adds. By the end of 2010, Taylor and Grangetto offered their first product to market – the dovetail fixture.

With machinists in mind

“This offering flowed into more tooling innovations, automation solutions, and modular systems that are adaptable and easy to use,” Huber says. “To this day, all our designs are created with the machinist in mind.”

Pioneers in automated manufacturing, production, and machining, today 5th Axis’ team of experts are committed to product development, milling, turning, assembly, plating, finishing, and logistics. They provide turn-key solutions for aerospace / defense, medical devices, consumer products, manufacturing processes, 3-, 4-, and 5-axis manufacturing, automated production, and project engineering.

5th Axis’ goal has always been to utilize the most cutting-edge software, equipment, and available technologies with the “best of the best” 3- and 5-axis high-speed machining from Germany, Switzerland, and Japan. All are exclusively programmed with hyperMILL® CAM software from OPEN MIND, a consequence of the company’s commitment to only use software that leads the field.

When Grangetto and Taylor started working on programming machines, they quickly saw that their existing CAM software was severely under-performing, unable to leverage the speed, power, and potential of their new high-end machines because of unforeseen machining collisions.

The path to hyperMILL®

For the purpose of testing out new CAM software for their high-end machining centers, the duo exhaustively viewed 5-axis demonstrations and interviewed manufacturers of 5-axis machines, and without fail, hyperMILL® was used to program every single 5-axis demo.

They used a challenging 5-axis object to investigate hyperMILL® and were satisfied with the reliable collision avoidance and effective tool routes. This demonstration of the software’s inherent ability cemented their decision, and encouraged by the positive feedback, they made the decision to use hyperMILL® themselves, which allowed them faster run times, better surface finishes, and overall greater part quality.

Additionally, they found that hyperMILL® CAM software from OPEN MIND offers a powerful module called MAXX Machining. By carefully managing material removal and, where appropriate, using smooth trochoidal tool path motion, hyperMILL® MAXX Machining creates very effective roughing tool paths, and permits feed rates to be regulated for the ideal cutting conditions rather than the most challenging cut, such a corner condition.

All of this attention to detail and precision aids in the goal of continually creating the products required to stay competitive, efficient, and profitable in today’s market, with machinists needing to look to automation that is not only reliable but affordable and locally sourced.

“If you look at the supply chain issues that face the industry, you have to ask yourself about costs of goods increase and skill gap,” says Huber. “What if your cutting tool, coolant, and raw material costs keep going up? What does your process look like if your lead machinist leaves? We need to own the availability of options in our processes and get in front of challenges.”

Modular work holding and automation will help offset and stabilize these variable costs because the company already possesses in spades one of the most valuable tools that a company can have, and that is continuous improvement, he adds.

In fact, what sets 5th Axis apart from similar companies is its dedication to building and providing the tools machinists need, built by those who know the industry best.

Comprehensive solutions

“5th Axis offers the most comprehensive modular work holding solutions,” says Huber. “Our products focus on interchangeability. When we started as a job shop, we had other systems that didn’t work together—open-source universal solutions that came out of the job shop. We had the perspective that we were using remarkable technologies, but we wanted them all to work together.”

Utilizing internal specialists, OPEN MIND postprocessors are built as a corporate core technology. To give the user the necessary control for their individual environment, postprocessors are customized and contain programmable parameters.

When 5th Axis programs really complex parts, having a staff of incredibly skilled technical support experts on hand, high-quality tool paths, advanced CAM software capabilities, and postprocessor support, these factors all work together to give them the confidence to take on increasingly challenging assignments. Because of OPEN MIND, 5th Axis says, it never wastes money by becoming bogged down in a task and in fact, their involvement has been crucial to the growth of the business.

When it comes to choosing between 3D printing, 3+2-axis machining, and 5-axis machining for overall quality and efficiency, there’s little doubt about choosing 5-axis machining, with the primary difference between the two being that while 3D printing is an additive process, 5-axis is a subtractive method.

When these two production strategies cooperate and strengthen one another, they perform at their peak. One method really cannot be substituted for another. 5-axis will always work best if you have complicated parts, a variety of materials, and a lot of labor required.

While 5-axis machining has many benefits, including better productivity, longer tool lives, and shorter lead times, these advantages depend on the quality of the workmanship and skill available to make it happen.

Finding the right people to set up the tool and manage the process to obtain these advantages requires more than just machining a part necessary to achieve the desired outcomes. It necessitates the right staff, training, and communication, all of which 5th Axis reliably provides.

By continually focusing on quality, experience, skill, and innovation, 5th Axis remains head and shoulders above the competition.

“Our products are designed based on industry standards and are even compatible with competitor solutions,” Huber says. “Our core focus is providing open-source solutions to make it work for the customer.”