As a leading Canadian supplier of innovative processing equipment, Firing Industries has enjoyed ongoing success. But the best two years in company history occurred recently – in 2020 and 2021, surprisingly – and for some very good reasons.

“2022 is starting like gangbusters,” says CEO Michel Dubuc. He observes that customers like to work with Firing Industries for its turnkey systems and one-stop-shop. “We do everything,” he says.

From conveyors to blenders, centrifuges, and pulverisers, Firing Industries’ team of experts provides essential equipment with a professional, knowledgeable, and consultative approach.

Founded in 1973, the company’s continual growth has come from its focus on providing a rising volume of supply to leading North American enterprises in the chemical, pharmaceutical, food, mining and minerals, foundry, and steel industries – and many other similar processing industries.

The pandemic has thrown up numerous challenges, of course, but Firing Industries has been determined to keep both its staff and business safe and profitable. That determination paid off.

“Michel was adamant. When there were insecurities and challenges abounding, he said that we’re not cutting staff, we’re not cutting hours or reducing wages, none of that, we’re keeping our teams as is,” says Danielle Dubuc, Business Development & Marketing. “He said, ‘we’ll work together as a team,’ and I think that’s a huge thing that should be talked about positively.”

Firing Industries has done more than just stay open and stand by its employees – it has had to actually increase staffing during the pandemic’s progression.

This ability to persevere regardless, coupled with the resources and skills of its own team of experts and the leading manufacturers it represents, not only enables Firing Industries to always be present and ready to assist its clients with their requirements – it’s at the core of the company’s mandate.

“At the beginning of COVID some orders were put on hold for customers,” says Michel. “It was hard, but within a month or so we needed manpower and everyone on board.”

The company’s products are unusually focused; closely related to each other in such a way that they often come up sequentially in a process. Along with Firing’s wide-ranging selection of equipment and an ability to provide complete planning for projects, this drives a synergistic and solutions-oriented relationship with clients and prospects.

So much so that it has permeated the company’s culture, leading to an attitude that encourages all the right questions to be asked.

“We have the resources, we have a lot of support from our contractors, and we’re able to face the music,” says Michel.

While he doesn’t want to reveal all, Michel says there are several projects on the go at the moment, including a tire recycling plant that’s been started up in eastern Ontario.

“We began that project with a customer in 2017. We did some pretesting on various feedstocks, and the plant has finally started, which is good,” says Michel. “We’re also looking at another facility, by the end of the year, with three times the capacity. Another good project, and multi-million dollars each time.”

There is also a deal in the works within the concrete sector involving special types of panels and compounds. “We’ve got two planned so far, and we have the possibility of delivering another three next year,” Michel says. “These large projects are keeping us quite busy.”

Although the company primarily distributes equipment such as metering systems and conveyors, Firing Industries still takes on new and major projects. Two large clients are currently involved in projects, and the company is looking to develop another two projects this year in totally different fields. Michel says Firing Industries will probably be adding more staff before long.

“I want to do a duplicate of a project I put together in 2020 and we want three more of these plants, hopefully in the next year,” says Michel. “We have the capability, but manpower is key. If you don’t have people today, you can’t move forward. There are always subcontractors, but they’re not part of your team. We have multiple subcontractors, though, and that’s very helpful.”

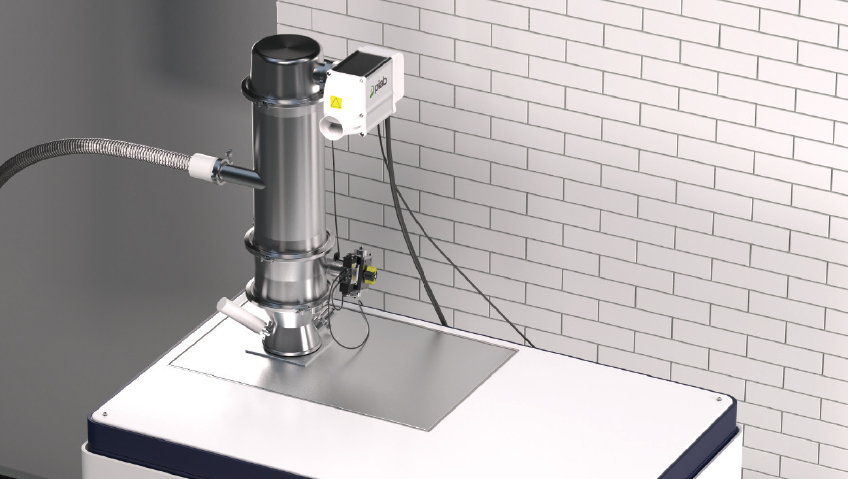

The truth is, whether it’s process development or installation services that customers want, Firing can source them from a number of leading long-term suppliers in North America and beyond, such as Hosokawa, Piab, Auburn Inc., NSEP, WAM, and Union Process Inc.

Michel says that Firing Industries draws clients because it has something special to provide. “The products we represent set us apart. Our suppliers are number one and two in their field worldwide, and the quality of the product we distribute is good. When we integrate into a system, we know it’s going to work.”

Companies they might be competing with have won’t have that advantage, he adds.

“The lines we distribute and put into our systems are top-notch. That’s the key thing. Also, we have long-term relationships with these suppliers – decades, and in some cases, multiple decades.”

These relationships make the company almost like a family affair, he says. Although its head office is now in Niagara-On-The-Lake, ON, Lars Firing actually founded Firing Industries in Montreal, in 1973, moving to St. Catharines in 1976. Some of the products Firing represents today they represented at that time.

One of the decades-long supplier relationships is with Union Process of Akron, OH.

“That’s ongoing and it’s going to stay,” says Michel. “When you talk to various members of that team it’s like they’re indirectly part of your team. It’s a very friendly discussion. We understand their product line and they understand exactly where we’re going.”

Similarly, the company has a 17- year relationship with Hosokawa, a billion-dollar worldwide company.

“Every time we position a system from Hosokawa, there’s going to be an auxiliary system we might already have from other principals that we can apply to that project,” says Michel. “It’s a good relationship to have with a group, and we’ll add equipment from other principals through that project. It’s a multiplying effect.”

This family attitude is strong within the company itself, a tight-knit group that’s successfully pulled together over the past few years to deal with COVID, moving the teamwork online when in-person wasn’t possible, and keeping sales up.

While many people may work three months at one job or a year at another, Firing Industries is proud of the number of its employees with more than ten years under their belts. “It’s a really good thing to have people who want to be at one company,” Danielle says. “Our employees are sticking around!”

Those long-time, dedicated employees are also part of the drive to provide customers with the best possible service. “We ensure customers out there know what we can accomplish, from ordering parts to turnkey systems to everything in between,” says Danielle.

“We’re lean and mean,” adds Michel. “We’re not big, but we try to react fast and pounce on every opportunity we can. There are a lot of balls in the air sometimes, but you assign the right responsibility and the right priority.”

For customers asking for spare parts, for example, it’s a pretty straightforward process, he says. “We go to our spare parts department, where we have two people dedicated to spare parts.” Customer satisfaction, and dedication to it, are not only paramount, but they can also have great financial results, particularly when it comes to all-important repeat business.

“If you’re looking at duplicating a project and the customer is satisfied with how you handled the first project, or the last 10 projects, then they’re not going anywhere else than us,” says Michel. “They’ll say, let’s do a duplicate of this, one phone call, update quote, and there you go.”

The level of satisfaction is the key, he adds, and while over the years there have been a few projects that could have been better, the majority have been exceptionally successful, even when pandemic supply-chain issues have seriously hindered progress.

One ongoing project right now, for example, is waiting on components delayed for more than two years.

“The supplier really suffered during the pandemic,” says Michel. “The customer knows we’re trying, but we have to face the music and the buck stops with us. We have to find solutions. That’s basically the motto of Firing – finding solutions since 1973.”