Technical Metals Inc. (TMI), a privately owned company based in Fairbury, Illinois, is a metal fabrication company which has been providing quality manufacturing solutions since 1970.

Before coming to work at TMI in 1980, President Gerald (Jerry) Hoffman, a Vietnam war vet, had earned a degree in mathematics and an MBA from the State University of Illinois, and spent a few years as Sales Manager at Strippit Inc., now part of the LVD Group that supplies sheet metal working machinery and software.

Over the past 42 years, through diligence and determination, Hoffman has developed TMI, a company his father began as a small one-man tool and die machine shop in 1970, into an 80,000 square foot operation that does business with hundreds of companies around the world. Its capabilities include welding, stamping, sawing, grinding, plasma cutting, and inspection.

This growth can be attributed to an “unwavering commitment to our employees, customers and community,” according to the company website. “TMI is continuing that trend by training dedicated employees to meet the demands of a constantly advancing industry, resulting in quality manufacturing solutions for today’s international companies and tomorrow’s global firms.”

As Hoffman told FMG Researcher Erika Arenas, TMI primarily uses raw materials from North America, although it does purchase some from Asia, but ships products made at its shop in Fairbury, a small town with a population of just over 3,000, to countries all over the world.

Company spokesman Seth Welch further explained the company’s strategy for success in a May 6, 2017 interview with Luke Smucker of the Pontiac Daily Leader.

“Although manufacturing is a fluctuating industry, TMI is at a competitive advantage. For the past decade, Jerry Hoffman, the company President, Caryl Hoffman, Vice President, and Becky Young, the Director of Operations, have worked hard to diversity the business’ customer base,” said Welch.

“We’re not just serving the energy extraction and heavy equipment customers; we’re also working with agriculture, forestry, and transportation. By diversifying our clientele, we don’t experience a big fluctuation like a lot of the big manufacturing companies do,” Welch concluded.

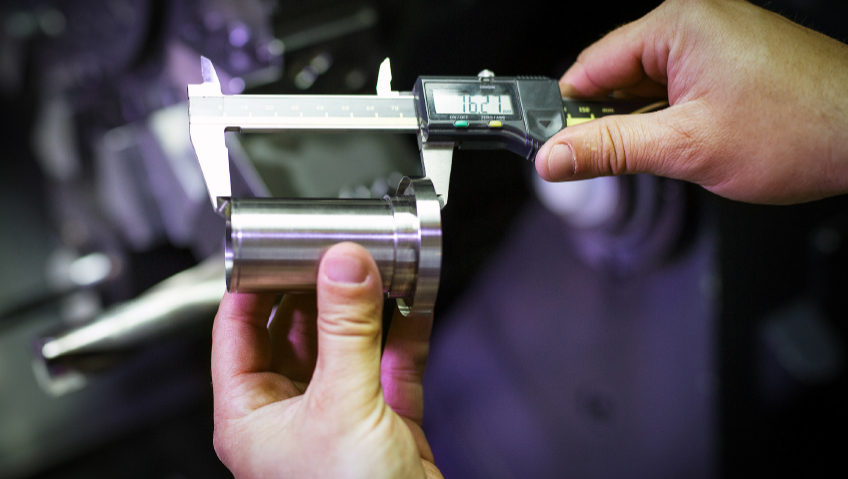

As a manufacturer of prefabricated metals such as iron, steel, and aluminum, TMI provides precision machine parts and metal stamping components and has made substantial investments in state-of-the-art equipment that provides the company with wide-ranging capabilities. This allows the team to perform some specific, intricate, and extensive work, producing over 2000 different pieces for customers.

When local radio host Paul Garcia was preparing for his interview with Hoffman about his Vietnam experience, he visited the TMI plant and later described the company on its Facebook page.

“I think it’s safe to say that 99 percent of people in this area have no idea how elaborate an operation this place is,” he wrote. “I was amazed by the technology they have and the sheer size of the place.” Among the equipment he saw was, “a laser that instantly made a 3D rendering of my hand. It’s an incredible place.”

It seems that whenever TMI acquires new equipment it makes the news. For example, the February 2012 edition of Manufacturing News featured an interview with Hoffman who had recently chosen “a Samsung mill-drill turning center, as a best buy for cost, features and availability. The larger diameter of the lathe was needed for shaft work, and other reasons for the choice included the turret size, live tooling systems, rigidity, and two-speed gearbox for low-end torque. This machine fit our needs.”

TMI’s website provides an up-to-date list of the state-of-the-art equipment that is ready to meet the exacting needs of its customers. Among them are seven horizontal mills and six vertical mills of varying sizes for milling, drilling, boring, reaming, thread milling, roller burnishing, grinding, and branching, with overhead crane assist for heavy parts.

In the grinding department there are seven grinders, including three with CNC capabilities, one manual, two surface, and one centerless capable of grinding lengths up to 12 feet to an accuracy of ±0025mm.

The lathe department has 19 CNC lathes with a range of sizes to accommodate precision shaft work and sub and twin spindles to maximize productivity, while the seven pieces of equipment in the welding department include robot welders with turntable and plasma cutter, a TIG welder for aluminum alloy steels and stainless steel, and two MIG welders.

The facility also has an abrasive waterjet, manufactured by Mitsubishi, capable of cutting through up to 8-inch-thick steel.

There’s an issue, however, with having so much highly technical, computerized precision equipment, and that involves finding highly skilled people to operate it.

As Hoffman told Arenas, that’s not an easy task. He places much of the onus on the educational system because it’s not training people to work in the sector, totally bypassing the skills needed. Moreover, teachers and guidance counsellors are “taking students away from the sector by telling them there’s no future in it.” But he believes the work is interesting and challenging, and thinks that young people who are interested in computers and grew up with them would enjoy it. Manufacturing today is not at all like it was years ago and that’s something young people need to understand.

Because staffing is such a big challenge industry-wide – and will continue to be in the future if this trend continues – Hoffman has started attending more high school job fairs and inviting students to TMI’s facility so they can see for themselves how interesting and challenging manufacturing can be. This was made more challenging for him by closures due to COVID, but he hopes to continue when possible.

In the next month, he told Arenas, TMI will be installing three new robots to improve productivity and delivery, and he is hoping this will pique the interest of students. Moreover, there are many benefits to working in manufacturing, including good paying jobs. With companies like TMI in the area, it’s not necessary for young people to leave their homes to find opportunities –not when there are opportunities waiting for them right next door.