At CRANE 1, customer service and safety are top priorities. And under the leadership of President and Chief Executive Officer Robert Vevoda, outstanding products – and an outstanding company culture to go with them – have kept the Miamisburg, Ohio-headquartered company growing and thriving.

Prior to joining the overhead crane and hoist services company, Vevoda served in roles that included President, COO, Vice President, Manager, Managing Director, and Regional Business Manager of some of the best-known companies in America. He was enticed to CRANE 1 by its potential, room for expansion, and great team members.

Soon after coming on board, Vevoda and his executive team embarked on several key initiatives, including creating a culture which was both employee- and customer-friendly while fostering a focus on customer service. Just as important for Vevoda and his team was ensuring that safety was CRANE 1’s top priority, establishing core values around safety that have made the company an employer of choice – and the choice of customers.

Much more than just buzzwords, safety and service are integral parts of CRANE 1’s mission statement, which is rooted in the basic principles of personal accountability, having safety at the forefront of everything it does, having a positive attitude and willingness to work in a team environment, being humble and having passionate customer service. These are the pillars of the company, and the principles that guide CRANE 1 every day.

Some companies abide only by guidelines set by the Occupational Safety and Health Administration (OSHA). CRANE 1 goes further, implementing safety procedures second to none in the industry. Soon after becoming President and CEO, Vevoda committed funding and resources to the company’s safety program. This included creating an on-site safety training center in 2016 and bringing in Tom O’Flaherty to lead the effort.

“Every new employee comes through the training center,” says O’Flaherty. As CRANE 1’s Safety and Training Director, O’Flaherty spearheaded the safety training center and program together with the company’s current leadership team and the guidance of Rick Smith, Vice President of Operations, and CRANE 1’s human resources department. Over the course of five days, new hires receive OSHA 10 training, along with special emphasis in electrical safety, aerial lift, forklift, crane operation, and more. The safety program is ongoing, occurring in the third week of every month. Since the course takes place in Miamisburg, it is a way to introduce the latest workers to CRANE 1’s core values, ensuring that they acquire all the tools to work safely and effectively.

While some recruits come to the company having already received some safety training, it is vital they are raised to CRANE 1 standards, which includes appreciating and understanding the company’s culture. “Safety is the one tenet we have that is non-negotiable, regardless of what their background is,” says Vice President of Operations, Rick Smith.

“We pride ourselves on our safety program and think it’s one of the most robust; and well-structured to where it is complementary to our technicians and not punitive, so to say. We try to foster a culture of safety, more than just rules of safety.”

When acquiring other businesses, CRANE 1 ensures the acquiree’s staff buy into the company’s safety program. “Typically, the businesses we are acquiring do not have as strict a protocol in that regard,” says Vevoda, adding that some other companies might not have the same structure in their programs or the money to invest in safety.

The first thing CRANE 1 does with every acquisition is ensure all technicians receive a new set of top-of-the-line safety tools, such as harnesses and other personal protective equipment (PPE). To ensure all PPE is in good working condition, the company performs monthly harness inspections, tracked through technology.

Founded in 2007, CRANE 1 started with seven locations, all acting independently. Valued at approximately $44 million when it was sold in 2015, the company steadily expanded over the next five years to 21 locations and made six acquisitions. More than doubling its number of employees, the business today has about 300 team members, over 200 service technicians, and operates in 15 states.

When looking for companies to acquire, executives at CRANE 1 ensure these businesses are complementary to CRANE 1’s value proposition to the markets.

In August this year, CRANE 1 was acquired by L Squared Capital Partners, a Newport Beach, California-headquartered investment firm focused on industrial technology and services, education technology, and tech-enabled services and software.

For Vevoda, the acquisition means even greater investment into people, infrastructure, enterprise resource planning (ERP), customer relationship management (CRM) systems, process-oriented software technology, and other areas.

“As we expand, we will need more people, from technicians all the way up to management ranks,” says Vevoda of the business, which so far has grown both organically and through acquisition. With the industry growing at about three percent, CRANE 1 is both growing faster and performing better than the market overall.

“The strategy is to expand geographically, to make sure that we are able to grow with our key accounts, like International Paper, at all the multi-site locations,” he adds. Starting mainly in the Midwest, the company has now moved into the Northeast, South, and Southwest, thanks to acquiring half a dozen small to mid-size companies operating in the overhead crane industry space.

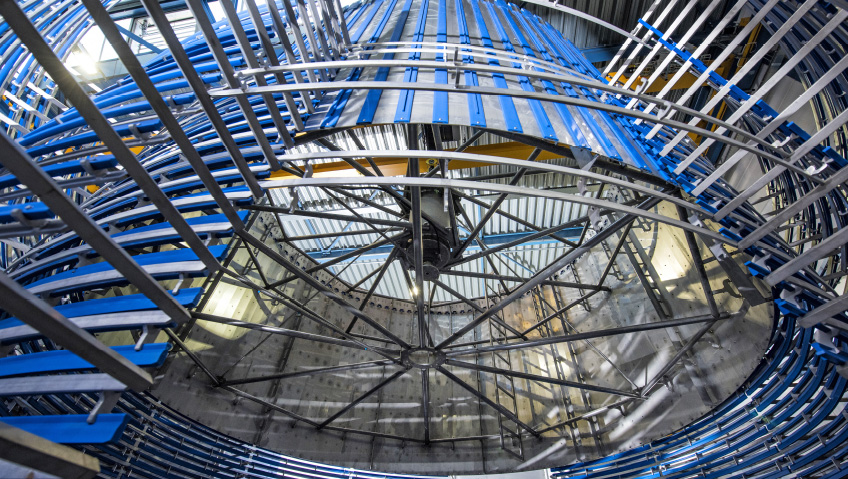

Believers in fostering outstanding service in America’s overhead crane industry, CRANE 1 “takes a consultative approach to create a partnership with our customers, formulating ways to improve their business performance by reducing their critical equipment downtime through preventative maintenance programs,” according to the company.

As overhead crane industry specialists, the skilled team at CRANE 1 can offer a unique perspective, one founded on decades of industry experience, and pass on this knowledge to customers big and small.

Since the company is not an original equipment manufacturer (OEM), the team can provide unbiased, informed advice about repairs and other recommendations based on their own experience, with the goal of addressing customers’ challenges to increase uptime, minimize downtime, and maximize the lifespan of overhead cranes.

So as part of its maintenance management system, CRANE 1 thoroughly analyzes new customers’ equipment. By undertaking appropriate preventative maintenance procedures, and so lowering the cost of emergency repairs, the company can save customers thousands of dollars every year.

“I believe we have some of the best-qualified technicians in the industry, with deep experience,” says Vevoda.

At CRANE 1, the company ensures all technicians are trained on the service aspect of the business. “One of our selling propositions is, we do not look at a customer’s crane as kind of a break-fix opportunity — meaning it has to break before we fix it — we look at it very holistically,” says Vevoda. As stated, this includes running comprehensive preventative maintenance programs and frequent consultations with the goal of more uptime and less downtime.

Through the CRANE 1 Advantage Program, the company helps clients reduce their cost of ownership by improving longevity of the equipment. “If we can extend the life of that crane by two, three, four, or five years, we’ve taken your total cost of ownership and divided it over 15 years instead of 10, so we’ve reduced the total cost of ownership over the life of the equipment. That’s how our program is structured,” says Smith.

And through its robust ERP system, CRANE 1 can track products and labor services, drawing up a report card for its customers. If there’s room for improvement in the program, they can fine tune as they proceed.

Recently introducing the Crane Assessment Program for larger companies wishing to improve and baseline their existing programs, CRANE 1 will provide an assessment of safety, maintenance, training, and operator qualifications, and maintenance validation.

Given a scorecard, companies can see if they are meeting the minimum expectations set by OSHA and the industry and are given a risk exposure score to see if they may be exposed to potential liabilities.

“It’s been well-received by customers who have partnered with us,” says Smith. “This is really for companies that take their maintenance and safety seriously and want to make it better.”

If a company is in the process of acquiring another business, the Crane Assessment Program can also be used during due diligence to provide a credible, independent, third-party evaluation.

Along with the Advantage and Assessment Programs, another reason customers choose to partner with CRANE 1 is its suite of products that complement a crane’s entire life-cycle from cradle-to-grave, from new equipment to modernization to refurbs, ceiling to floor. This includes the Below the Hook Refurbishment Group, something few other companies offer.

“We go from the hook to the floor,” says Smith. “That really serves us well in steel processing, where you’ve got big slab grabs, with these heavy lifting fixtures that usually connect to the bottom of the hook. Most people do not service those, and we’ve got a group that specializes in that.”

And through the company’s dedicated e-commerce-site for parts, hoistcentral.com, customers can easily and conveniently source what they need.

With the goal of doubling its revenue and moving into at least 10 other states in the next five years, CRANE 1 is actively hiring new members for its team – men and women who share the company’s core values.

“We look for the three A’s: attitude, aptitude, and ability,” says Smith. “People who have those soft skills bring value to our customers, while at the same time having technical skills that can deliver the products and services that we sell. So what differentiates us from the competitors is our selection process and people.”

Working on different ways to attract younger people into the trades, CRANE 1 also has a recognized apprenticeship program. The company partners with local colleges and trade schools to provide a four-year program, and also actively works to hire former members of the U.S. Military.

Someone about to exit the military can intern with the company for the last six months of their service, and at the end of their enlistment, they become a full-time CRANE 1employee. “It’s a really good program where they get to test drive us to make sure we are the right fit for them, and at the same time, we get to do the same thing,” says Smith. As befits a veteran-friendly organization, approximately 17 percent of CRANE 1’s workforce are themselves veterans.

Smith delivers the last word on this high-performance company and stand-out in its sector: “We are not a crane-service company, we are a business partner, because we understand the crane is just a necessity to get their product out of the door,” says Smith. “So we try to approach it from a holistic perspective. We like to think we are more of a partner than a vendor.”