Celebrating an impressive 30-year anniversary this year, Calgary-based August Electronics attributes that longevity to not only producing quality high-tech industrial and consumer electronics, but fully embracing its customer-focused approach that puts clients first in all areas.

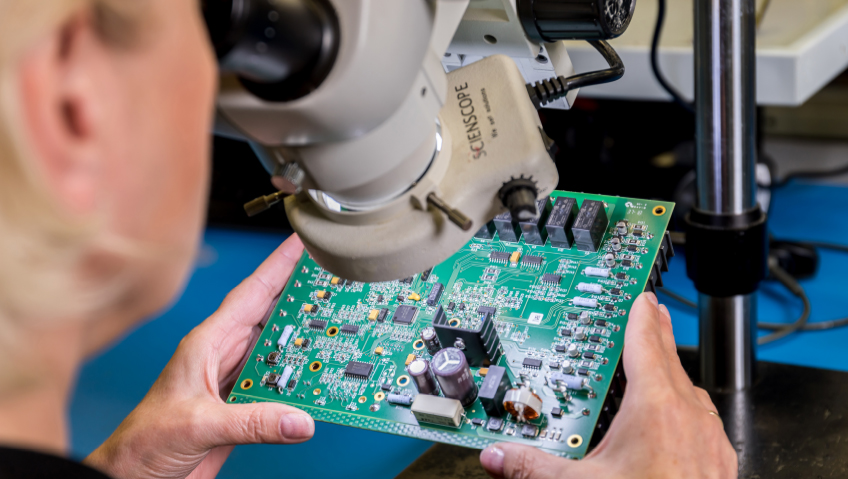

Founded in 1991, August Electronics is a 100-percent Canadian-owned and operated electronic manufacturing services (EMS) company that serves a variety of industries, including oil and gas, industrial applications, and recently, medical healthcare devices. The company’s 85,000 square foot facility is dedicated to delivering a “one-stop shop,” assisting customers end-to-end, from New Product Introduction (NPI) to providing Design for Manufacturability (DFM) and Design for Testing (DFT) feedback.

The business was created by Jack Francis and Peter Wilson, who met as co-workers early in their careers, combining their skill, knowledge and experience to build a flourishing company. While August Electronics initially also offered product design services, the company now fully concentrates on contract manufacturing via its in-house facility.

“August Electronics has a deep and successful background in the electronics industry,” says Tanya Korenda, co-owner and Chief Operations Officer. “The founders realized by working together they would be able to offer something unique and valuable to this EMS market we’re in.”

Over the past 30 years, the company has grown from two to about 120 employees, and now operates out of a state-of-the-art facility that provides expert client service. The company’s various ISO certifications — including 9001 and 1345 — and its APEGA permit to practice engineering ensure August Electronics is performing that service to the highest industry standards.

“Our certification really ties into our vision where we look to leverage our expertise,” says CEO Paul Crawford. “We want to be a trusted partner and a recognized industry leader for the electronic manufacturing services industry. The roadmap for our vision is to give our customers the highest level of quality and service, and also provide our people with the tools to grow their careers and strive for operational excellence every day,” he says.

“Customer satisfaction is really the key for our QMS, as it requires that we not only determine if the customer requirements will be met, but it also monitors the customer’s perception,” says Crawford. “That’s part of the feedback we get from our customers.”

Proper training is also essential, he adds. The company’s QMS helps everybody understand how their actions affect the products they’re manufacturing for customers, and paves the way for any improvements as well.

Crawford also attributes the company’s success to its ongoing dedication to customers. “We really believe in that team approach, and as we’ve grown, we’ve looked to assemble a team of highly skilled technicians and professionals with varied and complementary backgrounds,” he says. “We make sure we’re covering a broad range from the technical skills we need to the professional skills we need, so that everybody is working together toward a common goal.”

The company aims to not only be the manufacturing partner of its customers, but also to act as an extension of their team to deliver the highest-quality products, which leads to long-term collaboration and allegiance.

“Some of those customers we started with 30 years ago, and we’re still working with them now,” shares Crawford. “I think that really speaks to the idea of the term ‘partnering.’ It’s that whole concept of being an extension of our customers’ teams.”

That team approach means talking with clients – sometimes on a daily basis – about various challenges that might come up, or general discussions about what needs to be done on a project, and August Electronics prides itself on upholding this personal approach. “Often when companies get too large and successful, it’s hard to keep that intimate connection with clients, so it’s good if companies can maintain that over the years,” says Crawford of the challenges businesses can face as they grow.

The biggest challenge August Electronics is facing right now, however, is in regards to the worldwide semiconductor microchip shortage.

“Most industries across the world are facing this shortage, from car manufacturing to fridges and stoves; anything that uses electronics is going to run into this problem,” says Korenda. “In the more than 25 years that I’ve been in the electronics manufacturing business, I have never seen anything like this. We’re looking at lead times for semiconductor microchips that are going out 24 to 78 weeks.”

To help combat this obstacle, the August Electronics is working closely with customers on the problem parts that they’re not able to get, and looking to source them in different places, says Korenda. When they can’t be sourced elsewhere, August is working with customers directly to redesign any current designs they have in order to put in a component more readily available in the industry. This can translate to weekly, and often daily, meetings with customers to review their demands and the needs required to manufacture those parts.

“One of the other things we’re doing is working with the supply chain and the manufacturers of these microchips, and trying to provide them an outlook for the next 78 weeks,” adds Korenda. “This allows us to understand what kind of throughput they have to start working toward, and their recovery plans. We’re really trying to navigate this significant world shortage together.”

The repercussions of this shortage down the road could potentially be disruptive in different, never-before-seen ways. Korenda mentions that some manufacturers are actually planning semiconductor manufacturing plants in North America versus overseas to try and mitigate this problem and help to keep it from ever happening again, but due to the complexity of manufacturing microchips, it’s going to take a year to two to even get a facility up and running.

“That’s definitely the biggest obstacle we are going to be facing over the next few years, especially because we also have a growth plan in place that we would like to continue to work toward,” she says. “It will definitely be an opportunity for learning.”

Handling challenges is something August Electronics prides itself on embracing, and both Crawford and Korenda agree their customers see and appreciate the efforts, which is one of the reasons for the company’s longevity.

Future goals for August include company growth, of course, with a strategy that involves recruiting the right people to fill the right roles, along with providing proper support, guidance and training so that employees are the best they can be.

“We’re also constantly looking to automate and systemize our supply chain workflow, which will help us gain an advantage over competitors with the challenges we’re facing in our supply chain,” says Crawford of the move that will also reduce manual effort and increase productivity, efficiency and accuracy. “I think that’s really what sets us apart from similar companies – our team of people, the type of quality work we do, and our real commitment to continuous improvement.”

Korenda agrees. “The owners are morally grounded and really want to do what’s best by all parties, the vendors, the partners and our employees.”

“The company works in what I would term an ethical and caring way,” adds Crawford. “Obviously, all companies must be profitable in order to survive and August is no exception, but making money wasn’t all that was important to still having a company 30 years later. I think decisions are based on doing the right things for our people, our customers, our vendors, and always looking at it from that aspect.”

The pandemic has also brought the company together in terms of making necessary safety adjustments while maintaining revenue and dealing with unique and different working conditions.

Because of its depth of experience in the industry, the company is confident in its people, their skills, their expertise and their ability to continuously meet deadlines along with expectations. With state-of-the-art machinery and efficient work practices, August Electronics continues to proudly provide the services it promises.

Korenda adds that the company’s origins have gone a long way to ensuring that reliable, personal and professional service has been maintained even through much growth and success. “I think what has contributed to the success of August Electronics is that the owners are very honourable. I think that’s what’s kept them going for 30 years, and we hope to go another 30 more. It’s a great company to work for.”