The things we learn from our fathers can impact our lives in unimaginable ways. Dad’s advice can help us chart incredible careers, become corporate leaders or compete at the pinnacle of human endurance.

Manuel Gelerman credits his dad, a Montreal entrepreneur who immigrated in 1981 to Canada from the former Soviet Union, with an education and a dream, who instilled a strong work ethic and the foundation to achieve all of the above. Gelerman started working for his father’s tech company when he was 17 and he’s been on an upward trajectory ever since.

“He is a very sharp businessman, my father,” Gelerman says. “One of the things he taught me from a young age is to have a good nose and a great gut. So, you know, you have to smell the opportunities of your life during the life of the opportunities and have the guts to proceed with them.”

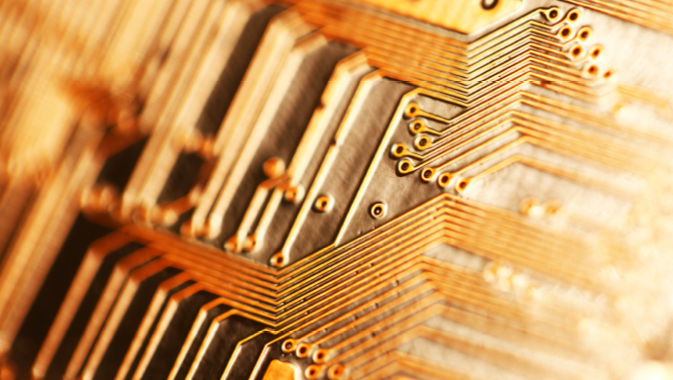

That’s exactly how Gelerman as CEO, alongside his business partner Claude Girard, have developed MPIQC, a contract electronic manufacturing service company that specializes in printed circuit board assembly systems. For the uninitiated, these devices, known as PCBA systems, are the backbone of most computational electronics, from your home tablet and smartphone you have nearby to complex communication equipment.

MPIQC, founded in 2011, is short for the Ontario company’s pillars of operation – Manufacturing Process, Integration and Quality Control – raising the bar for industry standards.

The level of expertise and dedication is a competitive advantage for original equipment manufacturer (OEM) clients across North America, Gelerman says. He is proud of his team’s ability to design and build turnkey systems and test “box build” assemblies for diverse electronics in aerospace, defence, medical, telecommunications, and high-tech industrial.

Essentially, MPIQC becomes a manufacturing partner to its clients, one that manages all the challenges in the supply chain.

“Our retention rate, when people come to us for solutions, is extremely high – in the high 90s,” he says. “We’re a good fit. We’re a value-add company. We want to integrate ourselves within the OEM, become their partner, becoming an arm of manufacturing that they require because of our experience. That’s what we do. That’s our core competency.”

Gelerman has a unique perspective and understanding of customer needs and expectations because he came from working in the OEM world for his father at the time with Advantech. His father has since sold a large part of the company in 2018 and rebranded the remaining business under Spacebridge. Both OEMs are still loyal MPIQC customers today.

“Another advantage is that I came from OEMs, so I know what the OEMs are looking for. I started as a buyer and what they look for partly is cost price – cost savings and unit pricing. It’s good to save money, but if your product doesn’t work when you get it, that means it doesn’t go to your customer, in addition to adding more delays, missed commitments and ultimately losing its reputation,” he explains. “We sell value and not cost price.”

MPIQC, however, stands first on quality, and offers an industry first two-year workmanship guarantee. Another market differentiator is the company’s tried and tested ability to manufacture a product from design through to customer delivery. The NPI process – New Product Introduction – is a complete prototype blueprint that takes an idea through various structured phases and results in a finished product launched into the marketplace.

Time-to-market is fierce and important, which puts an enormous amount of pressure on the OEM to deliver, Gelerman notes. That’s where the company’s experience and know-how take some of the stress off the OEM.

Going another step further, MPIQC also processes inventory management for its clients for direct to end-user sales and delivery, and handles maintenance and repair issues. So, if you need a full support network when it comes to electronics manufacturing, MPIQC goes above and beyond.

And Gelerman certainly knows about going above and beyond. Another gift bestowed by his father was his love for competition. Gelerman is a successful Ironman and brings that dedication, will, and commitment to all he does.

Case in point, one of the company’s clients in the medical field was working with very complex design and product materials that experienced issues while in production. The MPIQC team sat down with the client, looked at all the different issues and started troubleshooting. The customer’s partnering component manufacturers were also approached to assess the challenges and to provide their own insights.

“We were able, with our customer, to determine the root cause of the problem, which would have basically stalled a huge production and even bigger opportunity for the customer to get their product to market.”

The communication process is a key part of the company service. “You can come and bring us an idea and we can help you design it or help bring it to maturity,” Gelerman says of his approach to building client visions, products and developing relationships. “We can make it into a product by helping you build it under NPI or regular production, as we have the facility, the team and the processes to have it built right, tested and sent directly to your customer.”

To do all this, MPIQC has an impressive 85,000-square-foot facility equipped to deliver high-mix, low-to-mid volume production. Regardless of the need, the company has a solution designed to accommodate all facets from prototyping to volume production, in addition to processing modifications, repairs and maintenance. Interesting, too, the facility was originally built in the 1980s to manufacture and test military line-of-sight communication equipment.

In electronics manufacturing, quality and precision are top considerations – along with agility and speed to respond to customer requests.

“We can do quick-turn production, especially in regard to prototyping, while not cutting any corners. In several cases, with just 24 hours’ notice, we were able to turn around finished goods because we had all the stock in hand. In some cases, we can deliver same-day.”

Today’s market is competitive. When companies don’t want inventory draining their budgets, on-demand order and delivery is increasingly expected. MPIQC is well-positioned to accommodate its clients.

“It happens more and more that two to five-day turns are demanded, or major pull-ins of orders are requested,” he says. “We work around it and deliver, again never jeopardizing our ethics or quality in the process. If all materials are available and in-house, we can turn it around quickly.”

Gelerman is certainly the kind of driven individual OEMs want overseeing their electronics. In fact, running the business as a visionary CEO is a lot like running the legendary Ironman, he says.

“When you’re under pressure, you’ve got to keep calm. To run a business, you need to continuously educate and push yourself, and stay calm under pressure. In the Ironman, you’ve got to train smart. When you’re against the gun doing the race, you have to keep calm. It’s about making sure you think first and then react. That’s the key.”