At Inline Filling Systems (IFS) every project is exciting and new. Because companies with great product ideas and impressive marketing plans turn to IFS for the other element they need – namely, understanding how to turn mechanical processes into unmatched packaging solutions.

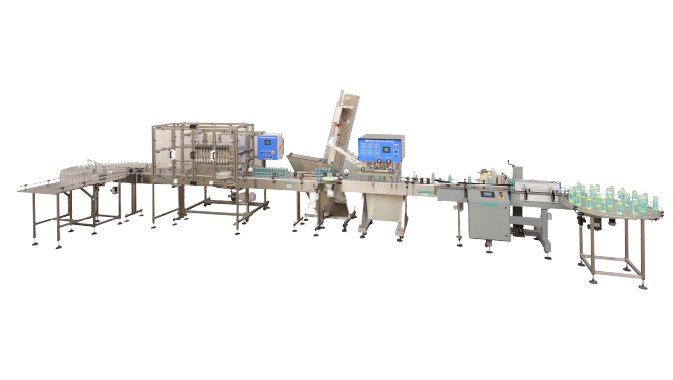

IFS is a full service provider of packaging solutions for a wide variety of liquid products, manufacturing packaging machines for cannabis, cosmetic/health and beauty, pharmaceutical, food and beverage, distilled spirits, automotive, cleaning and specialty chemical industries. It has the broadest range of filling equipment in the world.

In short, IFS creates Filling Machines for almost every flowable product there is for liquid products (with the one exception of counter-pressure filling machines for carbonated drinks). IFS manufactures Capping Machines, Labeling Machines, Conveyors and Turntables for both liquid and dry products. Its diversity across markets has generated exceptional growth, in size and expertise, for the last 23 years.

IFS is proud of this ability to engineer customized equipment precisely based on the clients’ needs. “We refer to ourselves as an application-based solutions provider. In other words, people don’t just buy machines from us, we make our systems and our machines work for what products they are filling, what containers they are using, and what caps they use, and then we guarantee our equipment works one-hundred percent,” says Scott Anderson, National Sales Manager at IFS.

Born in the USA

In addition, all equipment provided by IFS is manufactured in the United States, and almost all at its headquarters facility in Venice, Florida, where it also has an on-site service and parts center. When necessary, IFS partners with other manufacturers, offering clients the best solution possible (although IFS is firm about its U.S.-made requirement). “We integrate third party equipment that we don’t manufacture into our lines to offer a full line solution and then we support the third party equipment that we sell,” says Anderson.

IFS began its life in 1996 selling used equipment. However, it quickly uncovered an unmet need for a company that could manufacture machines for specific applications, and the business took off. Starting with simple turntable conveyors, its range expanded to various types of filling machines, capping machines, conveyor systems, labeling machines, and bottle transfer devices. The steady growth that ensued drove the company to expand its facility in Venice in every year since then and today it has approximately 50 employees.

Team philosophy

The staff at IFS work very well together as a team within the company philosophy that regardless of what position is held, each individual is equally as valuable as the next. Projects are not allocated to a specific small group of insiders; the entire team reviews each project piece by piece from beginning to end. This hands-on method truly guarantees the best opportunity for success because the employees are all invested in each and every project.

The recently established cannabis industry also greatly appeals to IFS, and the company has found that its vast experience transfers seamlessly to these fresh packaging challenges. Some new aspects need to be mastered and some new regulations likewise, however, there are far more similarities across product types than there are differences, and the transition has been smooth.

“E-cigarettes, edible oils, essential oils, beverages – so much of what we’ve done historically applies and most of the containers and labeling for those products are the same as in other industries,” says Anderson. IFS particularly values the opportunity to partner new people with fresh ideas and are excited about developing with the industry.

The company sells its machines globally and has forged numerous connections all over the world. When it began, during the infancy of the internet, IFS had a unique internet-based marketing and advertising plan that it used to propel the business by spreading the word about its American-made equipment.

The joys of quality

“People are still willing to spend more for quality equipment than otherwise because they understand the total value of ownership. Our machines will last 20 to 25 years and they run as tools for making money, not tools that cost money after the fact,” Anderson says, making a point that he clearly makes very often.

In fact, IFS has plenty of repeat clients who return when in need of more equipment because of the reliability – of both machines and company – that they experience. IFS has forged an enviable business out of turning new client contacts into loyal partnerships. These satisfied clients are an asset for IFS in another valuable way, too: word of mouth spreads fast and good references attract good clients.

“We’re obviously always interested in growing our business, not only for monetary reasons but if the company is growing, we’re also creating jobs and more opportunities for people. If we continue to grow, we’re going to do a better job at servicing the customers that we have. It all perpetuates itself,” Anderson says.

Money and people

For IFS, the aim of its drive for growth is to create more sales, develop more skilled employees, and expand its service offering to existing clients. As a result, IFS continues to reinvest in itself and its employees, the foundation of the company. IFS is planning for a smart growth trajectory, although not simply for the sake of growth, which might tend to result in dazzling numbers one year and a large correction the next. Stable growth allows the employees to feel comfortable yet also challenged and stimulated every day by the demands of fresh projects.

The company takes a simple, realistic approach to managing the business by focusing on employee and client satisfaction – successfully, it is clear, as turnover of staff is low and many of its employees have been with the team for more than 15 years. “We’ve got a lot of experience in the building because it’s a good place to work,” Anderson says.

Versatility

As manufacturing operations evolve and grow, they often add more SKUs and use a wider variety of containers, caps, and labels. Many of IFS’s clients have sophisticated and complex product lines that handle a range of varied containers and packages. To be truly valuable to one of these operations now, manufacturing equipment has to be versatile across multiple applications, yet easy to clean and maintain, and still easy to operate by the typical employee.

The achievement of IFS has been to make the equipment vastly flexible, without sacrificing quality or productivity, so as to provide its clients with the most efficient filling solutions. For IFS, the clients’ needs in this regard are paramount.

As a company that’s eager to learn, IFS says it is careful not to lead its clients down a familiar path for the sake of ease. Taking direction and listening with an open mind to the client’s needs and inclinations certainly does not mean that the quality of the final result will be compromised. In fact, it invariably leads to new and better insights.

“We’re always pushing the edge of the envelope based on what the customer wants, and we’re not afraid to take on new directions that may have been contrary to what we thought before, based on industry changes, so we always end up learning a lot,” says Anderson. The ability to adapt and to make changes on the fly are talents highly prized at IFS, which is important as projects don’t always follow a predictable path.

Cost and value

It is important to note that the cost of machinery is typically based on the cost of its components and the quality of workmanship. At IFS, the components can be verified and confirmed as FDA approved because the company does everything it can to prove the value of its equipment to its clients. All electrical systems bear the UL Listed Mark, signifying the global standard for safety.

IFS machines generally cannot be compared apples-to-apples with those of other manufacturers in its class, and this can sometimes mean a difference in price. It can be challenging at times for the sales staff to explain step by step the superior quality of the IFS brand. However, once decided, clients invariably find that going with the highest quality equipment available is justified over and over (hence the extraordinary rate of repeat business). “It’s more than just selling a machine today and then forgetting about it; it is a partnership when you consider the machines are going to be running for 20 to 25 years,” Anderson says.

The company will have a number of these machines – including the Piston Filler, Overflow Filler, Servo Pump Filler, Netweigh Filler and Capping Machine – on display at PackExpo in Las Vegas this September, where you can visit the team in Booth C3036. In December, IFS will also be exhibiting at MJBizCon, the largest gathering of cannabis business professionals, with 35,000 expected attendees, at Booth C1349.

The primary goal of IFS is to deliver the highest overall value to its clients, and to achieve this it is continually looking for ways to keep the company dependably strong, provide worthwhile job opportunities, and improve the services it offers through intelligent progress. Indeed, its mission statement encapsulates this: “Create value within the company through controlled, profitable revenue growth.”

Anderson concludes “I really look forward to coming to work every day because it’s a fun place to work and we have many very interesting clients that we serve all over the world. The opportunities here for personal growth and to create solutions for great clients – many of whom are friends after the years – are really gratifying.”