Grand Slam Safety is a prime example of how determination, innovation, and a deep commitment to excellence can turn a modest idea into a thriving business. What began as a small, grassroots effort to address a safety concern on a high school baseball field has evolved into an industry leader specializing in the planning, design, manufacturing, and installation of athletic containment systems. With a focus on customization and quality, the company has built a strong reputation over the years, not only in the United States but across the globe.

The idea for Grand Slam Safety came to life in 2008 during a local high school basketball game. Company President Bob Lyndaker, then a community member and passionate about sports safety, was approached by Jan Lehman, President of the school’s booster club, with a request: could they create a safe outfield fence for the school’s baseball field? This seemingly small problem sparked a series of events that would ultimately lead to the creation of a new company.

Lyndaker took on the challenge by dedicating himself to thorough research. “I spent a couple of months researching online, even consulting the U.S. Patent and Trademark Office website,” he recalls. “I couldn’t find anything, so I decided to build a model and share it with engineers.” His persistence paid off when he received positive feedback from engineers and sports industry experts, which inspired him to move forward with developing a prototype.

Alongside his close collaborators Bob Chamberlain, Dave Moore, and Mickey Lehman, Lyndaker presented the prototype to the local school board, who agreed to let them install the system as an experimental project. The successful installation at Beaver River Central School proved the concept, and Grand Slam Safety was officially founded in 2009. From this point, the company embarked on a journey to refine the product, secure patents, and eventually build a full-fledged business.

In the initial stages, the company faced significant challenges typical of many start-ups. The business operated out of Lyndaker’s basement and Advisor/Salesman Bob Chamberlain’s garage, and limited funding, a lack of specialized equipment, and the steep learning curve of entering a completely new product category made growth difficult. The early days were characterized by resourcefulness and ingenuity, relying heavily on personal savings and the support of friends and family. The founders were deeply committed to their vision of creating high-quality, safe systems for athletic fields, which kept them going through these tough early times.

By 2014, the company was ready to take a major step forward. It acquired a former paper mill in Croghan, New York, and transformed it into a manufacturing facility. This acquisition allowed the business to move from a small, makeshift operation to a full-scale production hub. “That’s when we really jumped into it with both feet,” says Lehman. “Even though the company was formed in 2009, 2014 was when we began manufacturing in earnest.”

The new facility provided the team with the space and resources needed to ramp up production and expand capabilities. What started as a team of a few people working out of a basement soon grew into a full-time staff of 34 employees. This included experts in a range of fields, from sewing and metal fabrication to welding, engineering, sales, and customer service. With these expanded capabilities, Grand Slam Safety was poised to make its mark in the industry.

One of the factors that sets Grand Slam apart from its competitors is its unwavering commitment to customization and quality. The company specializes in creating athletic containment systems tailored to meet the unique needs of its clients. These systems include outfield fencing, divider curtains, batting cages, wall padding, and canopy netting, all designed and fabricated in-house. “We thrive on providing customers with customized products and systems,” says Lehman. “We believe we offer some of the best products in the field.”

Lyndaker adds, “What’s surprising is how unique our full-spectrum approach is in the industry. We design, fabricate, and install everything ourselves, which isn’t common among our competitors.” This level of control over every aspect of the design and manufacturing process has allowed the company to produce some of the most high-quality and reliable products on the market. Whether for a school, sports team, or large organization, Grand Slam Safety’s products are built to withstand the test of time and provide superior safety.

Indeed, the company’s commitment to customization has garnered recognition from a variety of high-profile clients, including Major League Baseball teams. Its work has also extended to other industries, including space exploration, where it designed a specialized netting system to protect employees working with lasers in manufacturing. Although Grand Slam Safety keeps many of its high-profile clients confidential, its reputation for innovation and excellence speaks volumes.

From the very beginning, innovation has been a driving force behind Grand Slam Safety’s success. The company’s first two patents were for its original outfield fencing system, which has since been adapted for indoor use. Over the years, it continued to innovate, most recently with a groundbreaking quad divider curtain. This system allows multiple training spaces to be created within a single facility, making it ideal for soccer training facilities and other sports venues. The quad divider curtain also features an edge-seal containment design, which ensures that balls do not escape the training areas, a key feature for many clients.

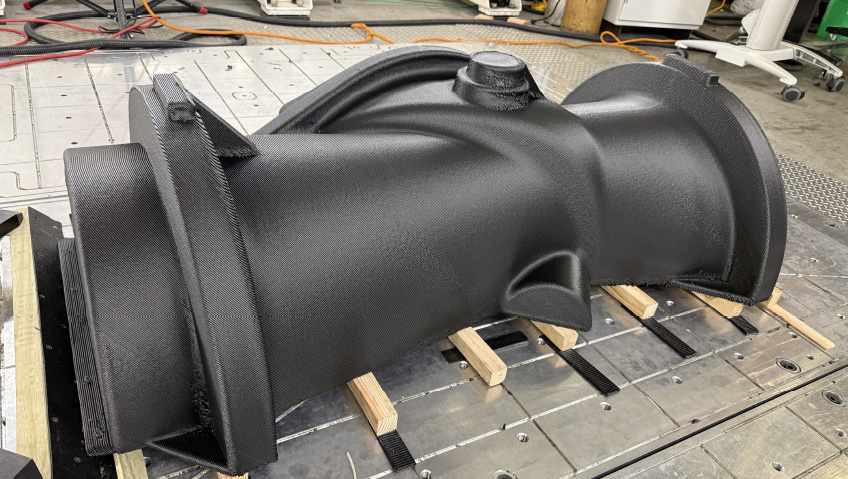

The company’s engineering, production, and installation teams have earned high praise for their craftsmanship, with manufacturing advances including 3D printing, programmable parts cutting, and vinyl/fabric welding. One notable project was completed in 2020, when the company was selected to install the backstop at the iconic Field of Dreams in Dyersville, Iowa, for Major League Baseball’s summer game. This prestigious project, along with several other accolades, including the New York State Empire Award, helped cement Grand Slam Safety’s reputation as a leader in the field of athletic containment.

While it initially focused on serving clients in the United States, the company quickly expanded its reach internationally. In 2016, it completed an installation at Bakhtori Field in Seoul, South Korea, and has since completed projects in Hawaii, marking its presence in all 50 U.S. states. “We’d like to do more work in Canada,” Lehman shares. “We’re building relationships there and exploring opportunities.” This international expansion reflects the growing demand for Grand Slam Safety’s products, which have earned a reputation for quality and reliability across borders.

The company is also well positioned for future growth, with plenty of capacity at its Croghan facility. “We have room to double production pretty easily,” says Lehman, highlighting the company’s readiness for increased sales efforts and regional partnerships. As Grand Slam Safety continues to expand its reach, it remains committed to providing exceptional service to its clients, no matter where they are located.

“Our growth has been organic,” says Lehman, “relying heavily on word-of-mouth referrals.” While these grassroots methods have served the company well, Grand Slam Safety is now looking to broaden its national network and expand its sales force. Building stronger relationships with distributors and identifying new markets for its innovative products are key priorities for the company as it looks to scale.

“We’ve grown so much since COVID, and it’s exciting to think about where we’re headed,” says Lyndaker. With a renewed sense of purpose and plenty of opportunities for innovation, Grand Slam Safety is poised for an even brighter future.

From its humble beginnings in a basement workshop to its current position as an industry leader, Grand Slam Safety has proven that dedication and innovation can turn a small idea into something extraordinary. As the company looks to the future, it remains committed to the principles that have made it successful: customization, quality, and continuous improvement. With new patents, an expanding international footprint, and a strong, dedicated team, it is well on its way to achieving even greater heights in the years to come.

As Bob Lyndaker puts it, “The potential for expansion and innovation is right in front of us. We’re excited for what’s next.” With a firm foundation and a clear vision for the future, Grand Slam Safety is poised to continue leading the way in the athletic containment industry for years to come.

Focus quotes:

“The founders were deeply committed to their vision of creating high-quality, safe systems for athletic fields, which kept them going through the tough early times.”

“The company specializes in creating athletic containment systems tailored to meet the unique needs of its clients, with systems including outfield fencing, divider curtains, batting cages, wall padding, and canopy netting, all designed and fabricated in-house.”

“What’s surprising is how unique our full-spectrum approach is in the industry. We design, fabricate, and install everything ourselves.”

“Grand Slam Safety has proven that dedication and innovation can turn a small idea into something extraordinary.”