While the economic and supply chain mayhem of recent years meant nothing but struggle for some businesses, others soared. One such superstar is Wisconsin Plastic Products, Inc., a plastic profile extruder that expanded its sales by around 60 percent from 2020 to 2021 and 34 percent from 2021 to 2022. Naturally, the phenomenal growth trajectory brought its challenges, but it also marked an exceptional period in Wisconsin Plastic Products’ history.

Based in Plymouth, Wisconsin, Wisconsin Plastic Products, Inc. mainly serves the United States’ Midwest, followed by national and international clientele. An interesting fact about the company’s best sellers is that, since 2020, giant extruded fiber optic raceways made from complex resins are by far its most popular product—supplied to the communications industry. This is followed by a range of sophisticated glass fiber-filled offerings, often with UV-resistant capstocks that serve the window and door market. The company is also favored by the luxury appliances market for the best in premium handles and trim componentry.

Pushing the limits of co- and tri-extrusion technology—where dissimilar polymers are chemically bonded and joined into a single extrusion—plus a lifetime guarantee on its tooling packages are not all that Wisconsin Plastic Products, Inc. is known for. The company also offers almost-unheard-of tight tolerances on its punching and cutting work. After three decades in the plastics extrusion industry, the company knows that partnering with its clients as a trusted extension of their businesses brings lasting relationships.

As a result, when COVID-19 hit, the company was well-prepared for a black swan event. “We had good backup supplier plans in place, and we learned how to put even better plans in place,” says Ryan Zolp, President. “It was a very difficult road to travel, but we certainly learned a lot from it,” he says regarding the unprecedented time, when some raw materials were impossible to source and, like everyone else, the firm had to turn to online communication to serve its clients best.

At Wisconsin Plastic Products, profile extrusion is considered a science that relies on its superb in-house tooling standards to set the stage for superb results. Manufacturing some of the continent’s biggest extrusions, ranging up to widths of 30 inches, the company’s fully equipped research and development department is headed up by a dedicated team of professionals in charge of product development and polymer research, all with the support of a strong engineering team. There is also the support of the International Standards Organization-certified quality control protocols, ISO 9000. The company is also certified by United Laboratories, featuring its mark of approval on many components and giving consumers peace of mind knowing that the company’s materials and systems are audited four times a year to guarantee best practices and product quality.

Employing a proprietary sizing system called vacuum calibration, Wisconsin Plastic Products ensures shape repeatability, tight dimensional control, and outstanding surface finish across the gamut of plastic types including rigid vinyl, acrylic, co-polyester, polycarbonate, ABS, and more.

“[Vacuum calibration] takes the element of human artistry out of the picture. So the quality of our extrusions is more so driven by the design of the vacuum calibration system,” he says. That gives the company a marked advantage over competitors employing air rack sizing technology, which depends heavily on the skills of their technicians. Just as every artist’s creation is unique, the same is true for technicians crafting with air rack sizing. The technician’s artistic influence can lead to shape variation from technician to technician and run to run.

Wisconsin Plastic Products offers many cutting edge specialty processes including Celuka Foaming. This extrusion process allows the weight of products to be cut in half, making it especially popular for bulking up walls while minimizing weight. The company can also add glass fiber to its products, increasing strength and flexural modulus. Alongside these specialty processes, the company also offers unique surface finishes employing its state-of-the-art embossing and hot stamping technologies. Wisconsin Plastic Products, Inc. has also introduced a protective coating called spatter coat. The in-line technology adds an appealing texture and limits fingerprints and scratches from end-user contact.

The company’s flagship process called Meta-Plast has helped establish its reputation for excellence. Meta-Plast provides a powerful bond between plastics and a range of metals like copper, galvanized steel, and aluminum through a custom co-extrusion system. “We get all the benefits of the strength and low shrink of the metal, but we also get all the flexibility and functionality of plastic in one composite extrusion. It’s incredible technology,” Zolp says.

The versatility of the resulting Meta-Plast composite lends itself to a broad range of high-volume applications including low-voltage power supply systems, mounting flanges (nailing fins) for the door and window industry, and heavy-duty LED light enclosures developed for optimal performance and lifespan in abusive environments.

Beyond driving innovation, the company also has an eye on environmental stewardship, engaging with customers to ensure that as much of its packaging and shipping materials as possible are reused and recycled to reduce waste. It also returns plastic scrap for recycling from companies that use its materials.

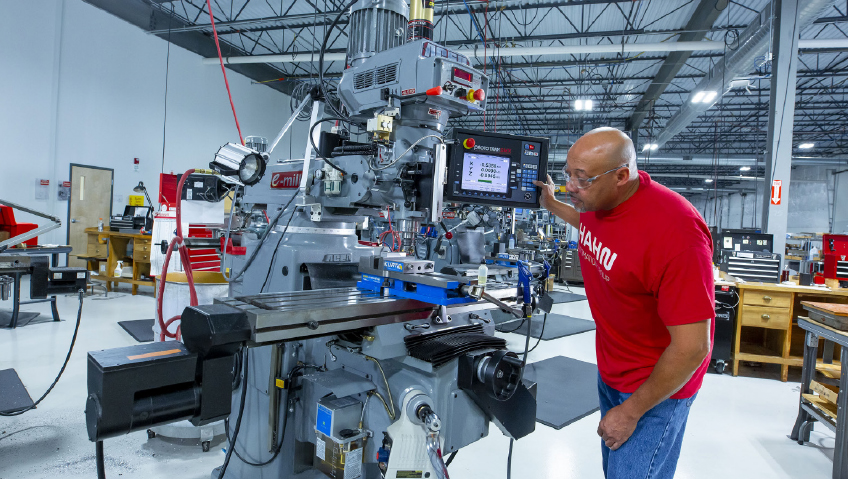

“We don’t give our tool shop enough credit. They are a huge part of the success of Wisconsin Plastic Products,” Zolp says. Complete with computer numeric control (CNC) lathes, multiple CNC mills, four wire electrical discharge machining (EDM) machines, EDM drills, EDM sinkers, and Haas vertical machining center, the team manufactures all of the extrusion tooling needs of the company and much of the downstream equipment.

The company was founded in 1994 by Brad Bruggink, initially as a turnkey tool systems vendor. Its initial business plan was turned on its head when the company agreed to become a third-party supplier of plastic extrusion components for a local office furniture OEM. Less than 12 months after taking on the contract for extruded plastic parts, the company became well aware of its core strengths and unique third-party proposition, and pivoted from its original systems manufacturing to supplying big OEMs with custom plastic components in what seemed like the blink of an eye.

By 1998, the proof was in the pudding and a larger facility had to be sought. This time setting up shop just under nine miles away, the outfit grew and its marketing efforts brought news of its dynamic capabilities to OEMs in industries it was not yet serving. The approach proved effective, and business soared. “It’s been a fun road these 30 years,” Zolp says, smiling. Of those three decades, he has been a part of 25 years of its success.

An expansion of 15,000 square feet and two new extrusion lines awaited in 2019 when the company had outgrown its 100,000 square foot facility. Growth became perpetual. Only three years into the new facility’s operations, more land was needed. The company added another 55,000 feet of manufacturing space, equipping it with six extrusion lines set up for a future of producing giant-sized extrusions.

In supporting company expansion, there is always time to do good for causes beyond its facility. Wisconsin Plastic Products is a generous contributor toward cancer research while also helping fund an annual holiday light show for the local community, to which some employees also contribute their time and skills. The proceeds of the event are donated to the local food pantry that takes care of the vulnerable across the county.

Zolp is full of praise for the company’s sterling team of 115, whom he describes as second to none. Focused on employing lateral thinkers, Zolp says that he stands amazed at the culture of innovation and continuous improvement across the board. The quality of training—including tuition reimbursements for employees committed to continuing their education—provided to all new employees, alongside apprenticeship programs, supports the culture. Therefore, when COVID hit, its people went into overdrive like a well-oiled machine and pulled the company through spectacularly.

“Kudos to the team. We found a way and got it done,” Zolp says proudly. The growth during the pandemic demanded improved systems, making way for the implementation of the company’s most recent investment, a next-generation enterprise resource planning (ERP) system.

“During the pandemic, we leaned on our management team harder than ever. I offer tremendous credit to the managers involved in training new employees during that [challenging] time,” Zolp says of the period that brought huge growth and with it an urgent need for clear-headed tenacity from all staff members. The period was marked by recruiting and training new team members in record time to continue serving customers successfully as markets changed post-COVID.

Subsequently, Zolp notes a particular trend in customer behavior where a bigger number of value-added benefits like graphics, double-sided adhesives, custom product cutting, as well as the inclusion of recycled materials in components, are called for compared to the past. The stress of the pandemic has created very close relationships between the company and its OEM customers. The Wisconsin Plastic Products engineering team offers itself as a helpful extension to the technical needs of the company’s customers.

A second facility is also on the cards over the next five years. While the jury is out on where the new facility will be, what is certain is that this plastics profile extrusion leader’s growth is going only one way—and that is up.