Designing and marketing software and equipment for panel and lineal processing that reduces cycle times, improves part quality, and removes extra waste from vinyl and aluminum extrusion machinery, the Joseph Machine Company (JMC) unveiled its first automated saw machine in 1986—still in use today—and has since migrated to its newest machines, CNC and multi-track processing centers.

Providing services to the automotive, window and door, lighting, transportation, renewable energy, and aluminum extrusion industries, this family-run business remains committed to creating the best equipment available, expanding the North American manufacturing ecosystem, and assisting clients and staff in achieving their goals.

“My dad Joseph started the company because he had run window and door manufacturing plants and was frustrated by the lack of automation,” explains CEO Anthony Pigliacampo. “In the ’80s it was very difficult to get skilled workers, and the process was very manual, so you not only needed a lot of people, you needed a lot of skilled people. As you grew, you were always running into that bottleneck.”

Joseph saw an opportunity to use automated machinery to increase output and improve quality and safety. Subsequently, he started building machines and selling them to other people.

“What we do is incredibly complicated and very risky,” says Pigliacampo of JMC today. “You generally sell an idea for a type of machine and a promise for what it can do when it’s nothing more than an idea. You sign a contract, and you have to deliver a real version of said idea.”

While being a family-owned business with no outside investors means having nothing to fall back on and creates pressure to be successful, it also affords the freedom to pursue ideas the company thinks are worthy. “Given that my dad started the company and believed in the benefits of automation, JMC was able to take a view and try things that other companies were unwilling to try, and that was really what my father’s vision was,” says Pigliacampo.

The last 38 years of JMC’s history are testament to the growth that has come from trying new, unproven ideas that Joseph believed in. “If we believe it’s a good idea and we think it will help our customers, we’re able to make those bets and take those chances.”

But taking chances through innovation and doing things to make customers’ businesses radically better also means betting on your team’s ability to deliver results. “Every month, if you walk into our company, there’s some machine on the floor that is a bet,” Pigliacampo says. “It’s a bet that this idea will make production faster, higher quality, and/or safer,” he says. “It’s really nice that we can make those, and I think it’s one of the reasons we’ve been successful for so long.”

Such an approach also creates an environment where the bottom line is measured by more than just a spreadsheet: being family-owned means treating employees like family as well. “The opportunities we’ve created for our team members are quite significant. We treat everybody like family, which is a bit different than a lot of other companies.”

“I couldn’t agree more,” says Vice President of Sales Thomas Vajdic. “The family atmosphere carries through everybody. Our core values speak to it, and every interaction is very family-based. A lot of our customers are also family-based companies, and it works well to interact with those companies on a family level. That’s what creates our partnerships, which is what we pride ourselves on.”

As the United States’ level of manufacturing has been “hollowed out” over the past few decades, JMC’s commitment to dealing with family-owned businesses is especially vital, particularly in bringing manufacturing back to the U.S.

“One of the reasons we sell to a lot of other family-owned businesses is manufacturing tends to be, in my experience, a lot more family-owned manufacturing businesses rather than institutionally owned or private equity,” says Pigliacampo.

In manufacturing in general, he adds, taking risks is key, and family-owned enterprises understand the business deeply. “What might look risky to an outside board that’s only looking at financial statements and Excel every month is not that risky when you’re in the business and you’re living and breathing what’s going on there every day.”

For him, even the family-owned billion-dollar companies he’s interacted with understand the “nuts and bolts” of what the company makes and how they make it at a much different level than the board of any mid-sized, publicly traded manufacturing company. “That’s one thing we’re really excited about, because we’ve been domestically focused for 38 years, and I think there’s a massive opportunity to do more manufacturing within the United States, which creates fantastic jobs,” he says.

In order to bring about such a shift, more automation and automated tools are needed as both the workforce and what people want to do in manufacturing environments are changing. During the last 20 years of manufacturing, the demographic of most manufacturing companies has aged significantly, with many people leaving the workforce and taking with them technical depth, knowledge, and understanding of how to do things.

“Younger workers coming into the workforce don’t necessarily have that background,” he says. “While it’s not that they can’t learn, it creates an incredible opportunity to say, ‘how do we do this better?’ The real opportunity for automation is changing what people think of manufacturing jobs.”

No longer inflicting physical wear and tear on the body, manufacturing at JMC is essentially a variety of engineering-centric jobs. From technicians who build the machines to those who design them to those who install them, these are incredibly complex technical jobs where people are maintaining the systems that perform the production.

“If you can make these systems, then have skilled people monitoring, you create these amazing jobs for people working within manufacturing. This is not only going to allow growth within the industries we’ve served to date but will also allow us to expand into other new markets.”

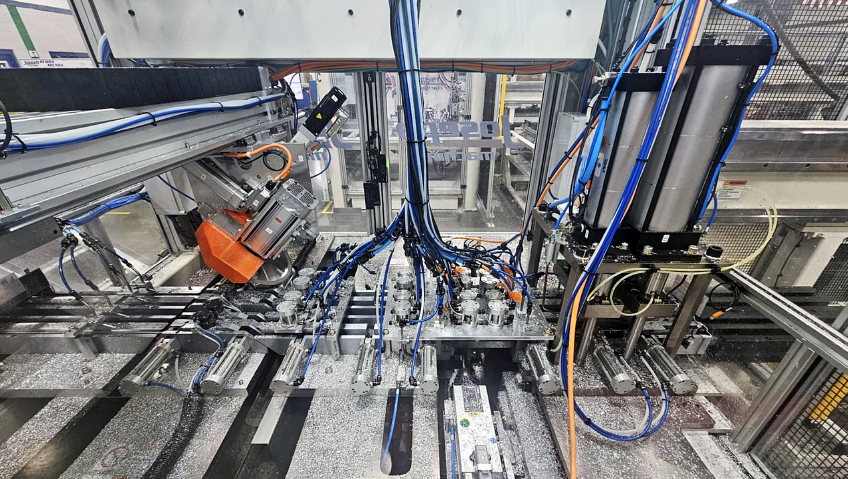

JMC prides itself on continually providing quality services and innovation, selling machinery that automates the production of end components—starting out with raw, large sticks of material, turning those into something else, then cutting, fabricating, assembling them, and turning them into something else again. The value adding going on throughout the machinery JMC sells has changed over time and is exciting from an innovation standpoint, with “the brains” of the machines becoming much smarter, allowing JMC to make “the bones” do more complicated things and be more flexible.

“Whereas things we used to do were incredibly dedicated to one specific thing, now we’re creating systems and solutions that might be able to do 10 things within the same footprint as what used to be able to do one,” Pigliacampo explains. “Those sorts of innovations really change the return on investment for automation.”

Indeed, JMC prides itself on being “very engineering-centric from the top down,” adds Vajdic. “That’s unique to us; we’re posed with a problem, and we come up with a solution from start to finish. From our technical sales to engineering, on-site, programming, and controls, we pride ourselves on the service we provide as an engineering team, that we engineer a solution tailored to a customer’s need. That allows us to innovate.”

One of the biggest challenges JMC has faced recently is how customers’ perceptions of automation “are grounded in the rearview mirror and not out the windshield.” Customers often think about challenges they had with automation in the ’80s and ’90s, spending money that resulted in large, complicated systems that were difficult to maintain and induced a lot of downtime. Helping customers understand that things are much better now than they used to be is key.

“Manufacturing isn’t something that changes very rapidly,” says Pigliacampo. “It took 25 years to offshore many processes that, if you went and saw them, aren’t actually that complex. Customers’ experiences from 10 or 15 years ago are still in some ways fresh in their minds, because that piece of equipment has a 30-year life and it’s still sitting on their floor somewhere.” To that end, it can be a challenge to convince customers that JMC has created some “amazing new technologies” that can transform how to do business by taking a chance and trusting the process.

From a business perspective, while the company is already fairly vertically integrated with a large machine shop, increased vertical integration remains a goal. JMC makes all its own electrical panels and some components, but if it wants to make larger, more complicated, automated tools, the more of the process it controls, the easier it is to roll out innovation in a cost-effective manner.

From the control side of things, JMC has revamped its control system for the future so it can expand on these products, changing the way its control system works to allow all in-house programming. “This allows us to be more flexible and more competitive in putting full lines together for automation,” says Vajdic. “We rolled it out and within a year were building 30-some access machines with the new control system. From that avenue, we’re also starting more flexible machinery for multiple uses.”

Customers who have multiple window systems or multiple systems in general are able to get more throughput through multi-track processing, he adds, through a flexible machine utilizing CNC and flexible tooling. “We compete against a lot of one-track, single-piece type CNC machinery,” says Vajdic. “We’ve identified a need for multi-track processing—and being able to do that in a fashion where the operator has less interaction with the machine; they load a stick of material and it flows through the machine and produces the product—in the aluminum world, with a new machine that we’ve developed which will be hitting soon.”

The JMC team spends a lot of time thinking about the themes its customers have talked about and highlights and how to solve those specific problems, creating a very user-centered design with everything it does.

The company also boasts solely United States-based manufacturing, with its machines designed, built, and tested in the U.S. “We pride ourselves on that, on being able to do everything here,” says Pigliacampo. “I think 85 percent of our parts are machined in-house.”

As JMC grows, it will continue to vertically integrate further, with plans for adding welding and powder coating abilities to create even greater self-sufficiency. And along with treating customers with care and respect, JMC is also dedicated to maintaining its positive impact on the community.

“It’s something we care a lot about—that’s a legacy our company has,” says Pigliacampo. “It’s actually bigger than our family, and because of that, we make decisions that are incredibly long-term,” he says. “We’re thinking 10, 20, 30 years from now, because our goal is to have a company that endures multiple generations.”