In 2002, the founders of what would become Framing Technology Inc. (Framing Tech), Jim Hartke and Chris Hill, decided to leave their positions in a multi-line distributor sales organization and strike out on their own. “Our expertise is promoting and selling and working with one product line,” they thought. “Why not do it for ourselves?”

Although their shot at the American dream did not come without struggle—a journey that saw the founders borrowing money and enlisting help from their families—the two persevered, with the happiest of results. Today, their considerable framing and extrusion business is established and flourishing in Rochester, New York.

A strong framework

Co-founder Chris Hill describes Framing Tech as primarily a B2B company, with clients spread across the United States. The typical client is an industrial automation integrator or equipment manufacturer that relies on Framing Tech products to serve as the skeletal support framework for their equipment. This can include enclosures around the equipment to keep personnel from accessing pinch-points, a process called “guarding.”

Other industrial applications for the company’s products include assembly workstations, incorporating LED lighting, tool or part presentation, monitor and PC mounting, and more. Automation and robotics companies also use Framing Tech products for perimeter guarding, acoustic attenuation, laser shielding, and vapor containment and exhaust.

Internally, the company’s framework is similarly strong, operating on a series of integral core values. Several of these core values specifically speak to customer relations, including conducting relationships with honesty and accountability. Hill says that the business is supported by an experienced team of more than 30 workers (many of them with decades of service), each dedicating their unique skill sets to the company’s overall success.

Framing Tech supports internal professional improvement initiatives for employees as well as inter-departmental cross-training, both of which contribute to building a multi-talented workforce. Hill says that this kind of approach helps everyone gain a fuller perspective on what the company does and equips them to handle the challenges of daily demands and responsibilities.

Engineering Manager Marcus Taylor says that the company is always focused on customer service. While a lot of other extrusion companies may try to sell everything at once, effectively watering down their capabilities, Framing Tech focuses on the frame itself, including efforts into frame aesthetics.

Going for good looks

Compared to the competition, the finish that is apparent on the company’s offerings is in a class of its own and showcases Framing Tech’s commitment to the quality of the final product. “Our engineers know we’re trying to make a premium product, and we don’t cut corners,” Taylor says, instead taking the time to produce products that represent the company at its best and reflect pride in craftsmanship.

When it comes to Framing Tech’s product offerings, quality and agility are of utmost importance. The company’s considerable product suite is frequently used in conjunction with a customer’s own equipment. As Hill says, “It’s especially important for us to bring the highest aesthetic to the client’s finished product.”

The company also serves individuals and DIY clients through e-commerce sales, partnering with Online Metals to sell products directly to its clients, like aquarium support frames, woodworking equipment, van conversions, and even PC gaming rigs, to name a few. Going beyond customer expectations of delivery dates, creative designs, and product solutions is a challenge that Framing Tech is always up for.

Always evolving

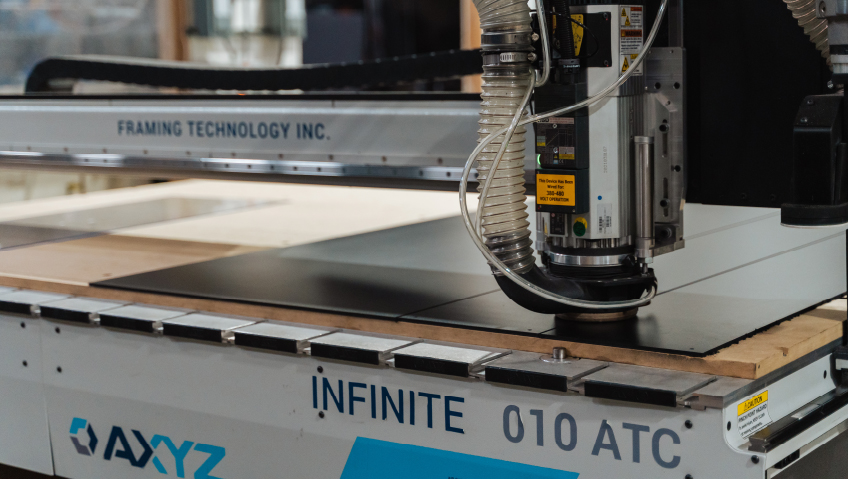

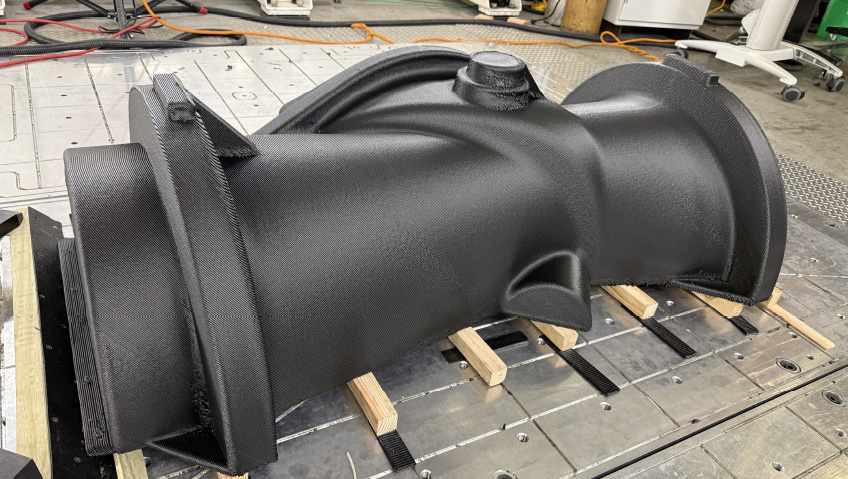

Evolution is another core tenet that Framing Tech has always held, as the business continually works on ways to improve its processes. Quite often, this involves expanding capabilities through new equipment, such as its water jet, press-brake, panel router, 5-axis profile machining center, additional SolidWorks licenses for computer-aided design, and more. Continuous improvement also impacts Framing Tech’s internal workflows thanks to investments like open-source ERP (enterprise resource planning) software that runs its entire platform and has given a large boost to internal efficiency.

Hill says that, among the innovations of recent years, Framing Tech has developed an extrusion-based construction for a belt conveyor that accommodates longer lengths, higher speeds, and payload requirements, and allows for shorter lead times. Its trademark Framing Tube, meanwhile, is a steel pipe-joint system that typically offers an option at a lower cost than aluminum profiles for applications like presentation stands, bin racks, product transport carts, and more.

Taylor explains that the company does a lot of work for workbenches and workstations, unique doors, access points, and similar. Today’s customers look to Framing Tech to consider issues related to factory worker comfort and ergonomics in its designs, and this shows in its work on pieces like electric actuators that go into products like standing desk builds and assemblies, with recent developments allowing for the delivery of a plug-and-play actuator system that makes it simple to account for ergonomic needs in these products.

Hill notes that five years ago, the COVID-19 pandemic had the entire industry scrambling as the company’s operations had to go remote for a while. However, he also says that the current state of the industry is about to change for the better. While the past couple of years have been consistent but generally flat, mirroring the dips in the U.S. economy, new federal regulatory policy and a renewed effort in re-shoring will put the company in a strong position to support growth with a 21st-century product, offering advantages in a broad variety of applications.

Taylor says that custom capabilities like the 5-axis profile machining center are amazing, with only 10 percent of Framing Tech’s customers utilizing the company’s full capabilities when it comes to custom machining and extrusion.

The Framing Tech way

Framing Tech aims to be a unique voice for its clients in the extrusion industry. Taylor says that a lot of companies in the space today are seemingly trying to offload the upfront design work to the customer, often in the form of online software that a client can design, print, and order directly from a website by building it themselves. This approach isn’t true to the company’s customer service model, as Framing Tech is a truly custom design house and manufacturing facility with everything set up to get quotes out quickly to clients (usually within two to three days) and shipping a fully assembled frame within a matter of weeks.

Looking forward, Hill says that Framing Tech is excited to continue its internal improvement efforts with its ERP system, and is focused on fully exploiting and better utilizing the capacity of available apps. The company will also be developing a new website, allowing for a seamless customer and user interface experience; the purchase of all products and solutions; and a full exhibition of service capabilities, as well as better customer service through the integration of live chat and the company phone system.

Framing Tech will be more proactive, too, in the approach of its sales department, becoming more engaged with the current client base and establishing new connections as it continues in its third decade. As Framing Tech looks ahead, its foundation of quality craftsmanship, dedicated customer service, and continuous innovation positions the company for sustained growth in a rapidly evolving industry. With a forward-thinking mindset and a strong internal culture, this company is well-equipped to shape the future of framing, one custom solution at a time.