Growth has been strong at GROB Systems, Inc., the Bluffton, Ohio-based branch of manufacturing equipment leader, GROB of Mindelheim, Germany. Since GROB Systems was last profiled in Manufacturing in Focus in 2024, the Bluffton plant has expanded its workforce, has introduced new products, and is looking to build its market presence. Most significantly, GROB Systems is now considerably bigger than it used to be.

“We finished our expansion, and we moved into our new building at the beginning of this year. I would say that’s the biggest change here in Bluffton,” says Thomas Neubert, Chief Sales Officer at GROB Systems, Inc.

Thanks to this recently completed 135,000-square-foot expansion, the Bluffton plant is now over half a million square feet in size. Physical growth has been accompanied by new hires; the team at GROB (pronounced “Grow-buh”) has grown from 839 people last year to roughly 950 today. “Our target is to get up to 1,000 this year, and then grow at about five to ten percent every year,” adds Neubert.

The Bluffton site and a substantial office in Troy, Michigan comprise GROB’s physical presence in America, while the parent company also has branches in Europe, South America, and Asia. The ISO:9001 and 14001-certified plant manufactures and assembles machining centers, automated palletizing systems, and assembly systems for battery systems and e-motors. “We do everything—the entire production chain,” states Neubert.

In addition, the team prioritizes “staying well connected” with its German headquarters, enjoying a regular exchange of ideas, plans, and even employees from the U.S. to Germany and vice versa.

In addition to its facility in Bluffton, GROB Systems is supported by roughly 45 service technicians throughout the U.S. and Canada, generally residing near areas where customers are concentrated. “It’s really helpful to be close to them to react quickly to any issues,” says Neubert.

About 80 percent of GROB Systems’ work is for the automotive industry, while its secondary markets include energy, aerospace, medical, die and mold, and defense. Among myriad other skills, GROB excels at manufacturing equipment that is used to make parts for electric vehicles (EVs). GROB’s G900F machining center, for example, was designed to process giga and mega-castings commonly used by EV firms to build their cars.

As of late, EV sales have been in a slump, and GROB has reacted accordingly, looking to enhance the amount of business it conducts with the defense and semi-conductor industries. GROB machinery makes parts for the former and computer chips for the latter, and semi-conductor manufacturing equipment “requires very high accuracies and extremely clean environments,” Neubert explains. “There must not be any trace of copper on the surface of the machine part, so if you have hoses or pipes where some coolant goes through and these are made of copper, then it doesn’t work. We are developing a special machine for those requirements.”

For its part, the defense industry requires high-quality, high-accuracy, ultra-reliable equipment capable of handling hard-to-machine components, he adds.

As Neubert makes clear, GROB has not abandoned the EV market, and remains committed to producing equipment to make components for battery cells (used in EVs and other applications). GROB’s parent company has taken this mission a step further and forged a partnership with another German firm, Dürr. The partnership aims to build factories that will produce lithium-ion batteries, and things are progressing well, with GROB outlining its battery-factory building prowess at trade shows in Germany and elsewhere. Last year, reports Dürr, the two companies expanded their machine and system portfolios for the production of battery cells and made them more efficient. Now, “we can provide an entire solution for a battery plant,” says Neubert.

Brand-new products from GROB include a Vario rotary table for the company’s G550 universal machining center. In tandem with the G550, this new system offers “a special table solution for turbine parts, as well as thin, slender parts,” notes GROB literature.

Meanwhile, GROB’s new PSS-R900 rotary pallet storage system features flexible configurability and is intended to augment efficiency, productivity, and output. Dubbed “Generation Two,” the PSS-R900 is “an improved version of Generation One, but is also cheaper and has more pallets and better connectivity. The real game-changer is that you can automate two machines with it. You can put two machines facing each other and in the middle is the pallet storage system serving both machines. So, you basically cut the costs in half,” details Neubert.

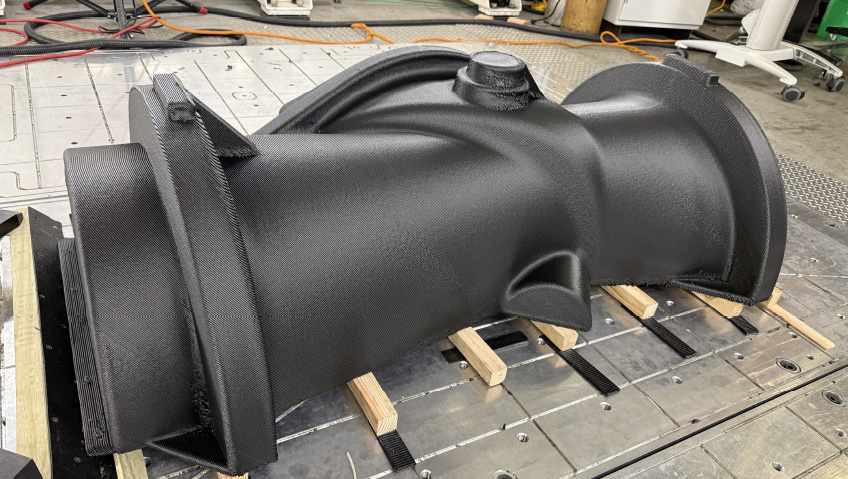

GROB also continues to modify and sell its pioneering GMP300 liquid metal printer. While most 3D printers produce parts made from plastic, the GMP300 uses various aluminum alloys to print components. Plans are afoot to expand the printer’s repertoire to include other metals and “allow [for] more complex applications, more complex geometries,” Neubert tells us. The team uses the GMP300 itself to make production components including “some parts for clamping fixtures and assembly applications.”

The company has also been tweaking its line of specialized robotic solutions. These include GROB Robot Cells (GRCs)—compact robotic systems that augment five-axis universal machining operations. The names given to these products include numerals that reflect their payload capacity; the GRC-R12 for example, has a 12-kilogram payload. GROB plans to add new sizes, functions, and tech features to its GRC lineup.

GROB Mobile Robots (GMRs) are autonomous guided vehicles (AGVs) that assist with centralized tool management and pallet storage. The basic machinery of these robotic vehicles hasn’t changed much, but GROB is focused on “constantly improving the software” used in its GMR models to boost performance, states Neubert.

GMRs don’t require human operators, which partly addresses one of the biggest challenges facing GROB Systems in Neubert’s view: manpower, or the lack thereof. “We have enough space here, we could easily build two more additions to the plant. But you need to find people, and find the right people,” he says of the Bluffton facility.

To this end, GROB Systems aims to develop new, skilled workers via its apprenticeship program. The four-year program offers a mix of mechanical and electrical education, classroom courses (paid for by GROB), and in-plant training. Apprentices who successfully complete the program earn a journeyperson’s certificate and are offered full-time work at GROB Systems, Inc. “We have grown from 2020, when we had about 20 apprentices every year… Now we are at almost 50 a year,” says Neubert proudly.

The company has also launched outreach efforts aimed at raising awareness of GROB’s purpose among high school and elementary school students and generating interest in manufacturing. “Everybody knows what a lawyer is, what a doctor is, what a teacher is. But nobody knows what a manufacturing engineer is. We want to create some excitement [around that] and it’s been pretty well received.”

In the same spirit, GROB Systems has been working hard to bolster its overall image. The Bluffton plant faces a busy roadway (Interstate-75) but conversations with existing and prospective customers indicated that few drivers who passed the plant understood its function. To remedy this situation, GROB Systems will be displaying large, highly visible banners outside the facility. These banners will contain product pictures and short blurbs along the lines of “We Build CNC Machines” or “We Build Assembly Lines,” states Neubert.

Hopefully, drivers will take note and gain an appreciation of what GROB Systems does. At the same time, the company continues to attend events such as trade shows, exhibitions, and conferences to network, demonstrate its wares, and keep abreast of trends.

When it comes to developments within the manufacturing sector, Neubert expresses concern about the U.S. government’s newly imposed tariffs on imported products and materials. While GROB Systems makes equipment in America, it relies on supplies from outside the U.S. which might be subject to import duties, raising production costs for the firm. Staff from GROB Systems “have talked openly with our customers. We had a good conversation with them” regarding tariffs and possible price increases, says Neubert.

Remaining well-informed and “updating your business plan accordingly” is paramount in this new environment, he adds. “The biggest challenge is really that there is no certainty about what’s going to happen. If we know, okay, the tariffs are there for the next ‘x’ years, you can work with that. But it seems like it could change at any time, so you have to be very agile and flexible.”

That said, some changes on the global economic front do bode well for GROB Systems. While the EV market is stagnating, interest in battery cell production remains strong, which plays into the company’s strengths, says Neubert.

“The U.S. and the entire world are trying to be less dependent on China. There’s a lot of battery manufacturing in the U.S. and they need equipment, and maybe this equipment should come from a different place than China. And we are, I would say, the only company of this size that can handle such projects in the U.S. and build here as well. That’s one area where I see very good potential,” he states.