In 1977, a small, family-run business began with a vision and a pickup truck. That vision grew into Dellinger Enterprises Ltd., a leading provider of custom metal fabrication and machining services.

The company’s story started with Larry Dellinger, a mechanical engineer, who founded the business with a shoestring budget of about $1,000. “He started with a pickup truck and a vision,” recalls Greg Dellinger, co-owner of Dellinger Enterprises and Larry’s son. “From there, we bought equipment, grew the business, and expanded into new areas of fabrication.”

As the company grew, so did its capabilities. With Larry’s engineering background, Dellinger Enterprises evolved into a full-service shop that could handle both machining and metal fabrication, making it a unique “one-stop shop” for clients. Greg, who joined the business in 1980, recalls working alongside his father and learning the trade from the ground up. “We combined engineering with craftsmanship,” he says. “My dad’s mechanical engineering background and my passion for metal fabrication worked well together, and that’s how we created what we have today.”

Over the years, Dellinger Enterprises has served some of the biggest names in industry, from Pittsburgh Plate and Glass (PPG) to Monsanto Corporation. “We shipped equipment to places like China and Venezuela. We built machinery and sent it abroad to support industries that needed specialized equipment,” says Dellinger. The company’s versatility became one of its defining features, with the ability to not only produce large-scale projects but also handle custom orders for smaller or more complex fabrication tasks.

Today, under the leadership of Greg Dellinger and his team, Dellinger Enterprises continues to thrive. With a diverse range of services and a deep commitment to quality, the company remains a key player in industries like automotive, pharmaceuticals, and aerospace.

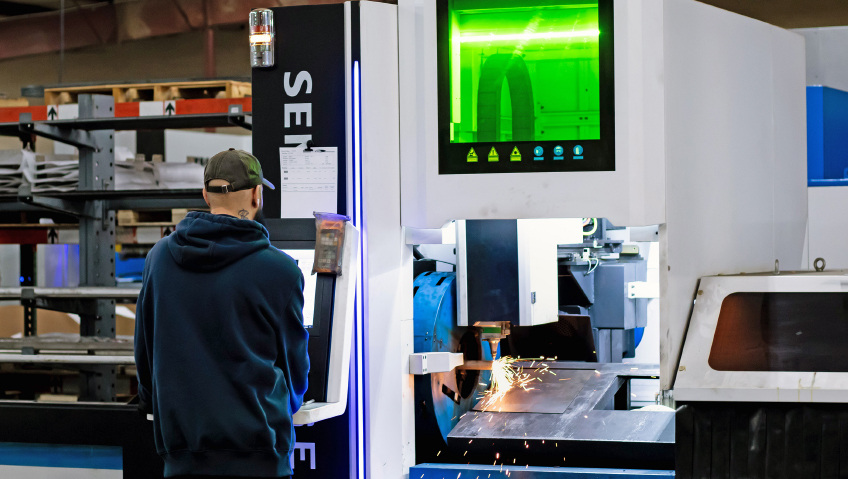

What truly sets Dellinger Enterprises apart is its ability to offer an all-inclusive range of services under one roof. As Austin Corn, Process Manager, explains, “We’re able to take a part from flat sheet metal and make full projects out of them. Whether it’s large assemblies or intricate parts, we handle everything here—machining, welding, sheet metal bending, laser cutting, and assembly. A lot of suppliers only focus on one aspect, but we do it all.”

Dellinger Enterprises offers comprehensive services that allow clients to work with one reliable supplier for complex, multi-faceted projects. From precise laser cutting and CNC machining to welding and sheet metal bending, the company handles the entire process, making it easier for clients to manage their orders. “Our ability to combine all these services in-house really sets us apart,” Corn adds.

In addition to traditional fabrication methods, Dellinger Enterprises is also focused on staying ahead of technological trends. “We’re constantly working to upgrade our capabilities, whether that’s through new machinery, advanced software, or automation. We’re always looking for ways to streamline production and increase efficiency,” Corn explains. For example, the company uses state-of-the-art press brake software and is investing in welding robots to help improve precision while maintaining its strong workforce.

Quality has always been a core value at Dellinger Enterprises, and under the guidance of Ethan Marr, Quality Manager, the company takes great pride in meeting and exceeding industry standards. “We invest in cutting-edge technology to ensure our products meet the highest quality standards,” says Marr. One of the company’s most recent innovations is its use of 3D scanning technology, which allows for detailed dimensional analysis of parts. “We use a 3D scanning arm to compare physical parts to customer models, providing a heat map that shows exactly how well the part conforms to specifications,” he explains.

This technology is particularly valuable in industries that require precise measurements, such as automotive manufacturing. “With this capability, we can handle even the most challenging quality requirements, like geometric dimensioning and tolerancing (GD&T), which is often used in the automotive industry,” says Marr. The company’s dedication to quality is also reflected in its ISO certification, a mark of excellence that assures customers that Dellinger Enterprises follows internationally recognized standards. “Our ISO certification is more than just a piece of paper; it’s a commitment to continuous improvement and ensuring the best possible outcomes for our customers.”

Another defining characteristic of Dellinger Enterprises is its family-oriented culture. This culture was instilled by Greg’s father, Larry, and continues to guide the company today. “We try to create a positive, family-like environment,” Dellinger says. “It’s not just about the work; it’s about the people we work with. We treat everyone here with respect, and we foster an environment where employees feel empowered and valued.”

With an average of 37 years of experience among the senior management team, the wealth of knowledge and expertise within this company is unparalleled. Teresa Edge, Office Manager, emphasizes the strength of the team. “We have about 30 employees, and the average length of service is impressive—our senior team has an average of 37 years with the company,” she says. “This experience allows us to run efficiently and maintain high standards.”

This long-term dedication helps Dellinger Enterprises achieve high productivity and output despite its relatively small team. “Our team is small, but we work like a much larger company. The expertise and experience we have allow us to operate with the efficiency of a much larger team,” says Edge.

As Dellinger Enterprises looks to the future, the company is focused on expanding its capabilities and staying ahead of industry trends. “We’re investing in new technologies like 5-axis laser cutting and machining, robotics, and AI integration,” says Dellinger. “We want to make sure we’re not just keeping up with the times but leading the way in manufacturing innovation.”

The company is also working to expand its reach globally. “We’ve always been a company that thinks beyond borders,” Dellinger reflects. “We’ve shipped products to Canada, Mexico, and even Taiwan. Today, we continue to serve clients across North America and internationally. Our ability to adapt to changing market conditions and new technologies has allowed us to stay competitive.”

Dellinger Enterprises has a forward-looking strategy that includes focusing on emerging industries like electric vehicles and renewable energy. “We’re actively pursuing projects in these areas because we see them as key drivers of growth in the future,” notes Corn. “The beauty of our business model is that we’re adaptable—we can work with any industry that needs our services.”

Indeed, one of the core values of Dellinger Enterprises is building lasting relationships with clients and suppliers. “We follow the golden rule: treat others the way you want to be treated,” Corn explains. “That means treating our customers and suppliers with the same respect and care that we expect from them.”

This philosophy has helped the company thrive even in challenging times. “We were considered an essential supplier during COVID-19, and we never shut down. Our diversification allowed us to weather the storm and continue supporting our customers through uncertain times,” says Dellinger.

The company’s reputation for reliability and personalized service is one of the reasons it has maintained such long-term relationships with its clients. “A lot of our customers have told us that what sets us apart is our communication and customer service,” says Marr. “They feel like they’re really listened to and that we’re proactive in solving any issues they face.”

Dellinger Enterprises Ltd. is a testament to the power of hard work, innovation, and family values. From humble beginnings in 1977 to its current status as a leader in metal fabrication and machining, the company has grown by staying true to its core values of quality, efficiency, and customer care. With a forward-looking approach that embraces new technology and a family-oriented culture that empowers employees, Dellinger Enterprises is poised for continued success in the years to come.

As Greg Dellinger puts it, “We can’t change the world, but we can make a difference in our own business, and that’s what we’re focused on—creating a positive work environment, providing quality products, and staying adaptable to meet the needs of our customers.”