Phillips Corporation knows how to solve problems. The Hanover, Maryland-based business has been tackling manufacturing challenges for the United States government, industry, and education leaders for more than 50 years. Over the decades, the company has built a global presence and forged strong partnerships with technology leaders including Haas Automation. Now, the company has launched a new era of hybrid manufacturing with a lineup of hybrid additive solutions, powered by Haas.

The company’s new hybrid offerings were first launched in conjunction with software company Autodesk. “Autodesk had reached out to Haas Automation, which we’re a distributor of in our commercial and federal business,” says Hybrid General Manager Brian Kristaponis. “Haas didn’t have a hybrid offering. They knew that Phillips was involved with additive and kind of made the connection, and then we decided to work with Autodesk to build them a machine.”

After building for Autodesk, the team recognized that there was a wider market available to them. “We realized there was interest from the U.S. Army and U.S. Navy, so we built a smaller sister machine to the first Autodesk machine,” says Kristaponis. The product was an immediate success. “The Navy followed up with additional orders and is now currently our largest customer.”

This success motivated the team to create more of these systems. Soon, they needed to launch a standalone business unit inside of Phillips Corporation to meet demand from a range of customers within the Department of Defense, commercial industry, and academia. Today, the division supplies around 60 systems across various markets.

The Phillips Corporation advantage

The hybrid team’s complete service approach plays a critical role when it comes to customer satisfaction. “Our hybrid team is very unique,” Kristaponis says, due to their ability to deliver a full, turnkey solution. “We start from the software side, on to building the machine, and to training the customer. Our hand is in every step that a customer [needs to follow] to make them successful. A lot of resellers may have some loose arrangement with a software partner; we’re developing the actual post processor, the converter file. We’re developing the machine simulation and training the customer. We’re the one-stop solution with this technology, and I don’t think anyone else does that.”

“We’re not just there to install the machine,” adds Hybrid Sales Manager Alex Potts. “We install, we cover training, and we’re always here for support both remotely and, if need be, we can always come back to site. Every one of our hybrid applications engineers is well versed in at least one programming CAD/CAM software suite; most have two or three under their belt. So just having that versatility and ability to work with pretty much any customer [differentiates the company]. We have somebody who’s an expert with that program to help them.”

Having experts who are well versed in both additive and subtractive technologies streamlines the customer experience. Rather than sending two separate application engineers onsite, the team need only send one expert. “Having one person to do both simplifies the process,” Kristaponis says. “Because if you had two separate trainers to train on these systems, there’s always going to be some lack of continuity between those trainings. Having the same person with experience in both really helps our customers learn these systems.”

Target markets

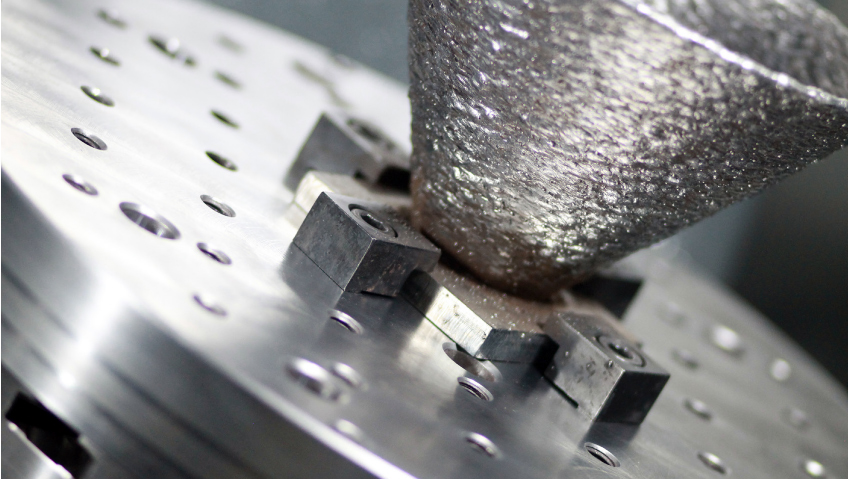

Education is one of several target markets for hybrid additive solutions. “A lot of universities are doing research, often in conjunction with the Department of Defense, and so using a hybrid system allows them to process different wire materials and in some cases, powder,” Potts explains. Phillips’ Laser-Powder Hybrid system gives researchers the advanced technology they need, including the ability to control different variables on the laser and mixing materials to create functionally gradient alloys (FGAs).

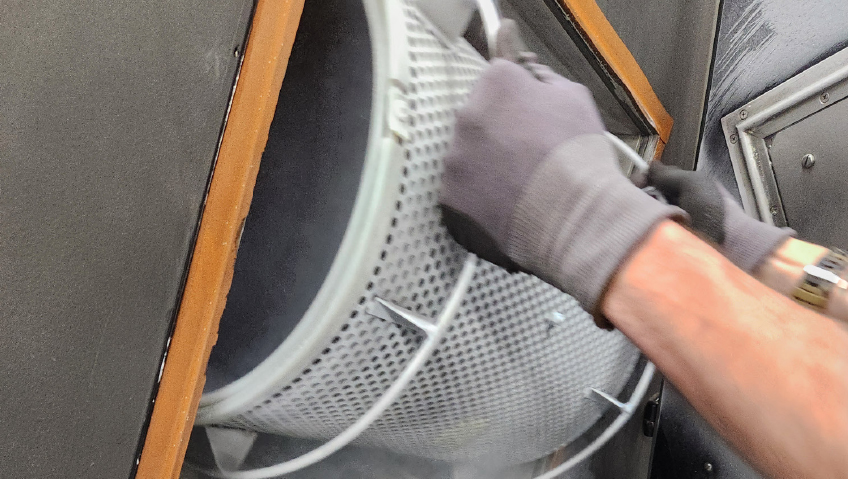

The company’s hybrid systems can also be used to give students hands-on experience. Vocational schools as well as four-year colleges can utilize Phillips’ Wire-Arc Hybrid, which combines CNC and welding capabilities, to train future workers.

The Department of Defense is another key target for the company’s solutions. “The DoD is really interested in deployable systems,” shares Kristaponis. Phillips’ hybrid systems use commercially available wire that “can be found anywhere in the world,” he continues. “If you’re in a base in the Middle East, commercially available welding wire is there. If you’re in South Africa, you know it’s there. It doesn’t matter where we’re at in the world, we can find commercially available wire—and that’s not true when you talk about other additive manufacturing technologies.”

Equally important is that Phillips’ systems use commercially available welding gas, rather than the ultra-high purity requirements often seen in other additive metal processes. “So logistically, the items that we need to make parts can be found anywhere in the world,” Kristaponis says.

The ruggedness of the system also comes into play, especially with the Wire-Arc product. “You’re not worried too much about contamination,” says Hybrid Applications Manager Randy Behm. The Department of Defense needs “to have a robust, reliable product that’s going to work where it’s needed.”

Another advantage is that Phillips’ hybrid division “can scale into large parts,” Kristaponis says. “We can scale this indefinitely.”

Ease of use is another major factor. “The military already has programs and specialists who are focused on machining,” Behm points out. “They’re already very familiar with Haas and that interface, and we’re building on that foundation.” This reliable foundation combined with traditional manufacturing workflow makes it easy for newcomers to get the hang of the system. “Being able to have it on a platform that’s easily learnable and have as much of that knowledge transferable as possible is important for the DoD,” he says.

Overall, Phillips’ hybrid solutions increase military readiness by decreasing the lead time to source material and manufacture parts. In addition, the military can “manufacture these parts without reliance on outside entities, without having to get castings from another country,” Behm says. “We’re realizing that now we need to be able to make things without relying on other countries, specifically for military applications.”

The hybrid division thus offers a full suite of solutions to meet the needs of diverse sectors. So how do customers determine which approach best suits their application? “One of the things we added to our website is essentially a tool that customers can fill out to help make the decision, or at least introduce them to the right path,” Kristaponis tells us. The tool considers everything from which feature size is ideal for the application to how fast the deposition rate needs to be.

Most importantly, it considers what type of material the part needs to be made from. “That usually dictates what technology they should go with,” Kristaponis says. “That would be the first parameter. The second parameter would be part size. And with those two, [the customer] usually can make a decision of what technology makes the most sense.”

Looking ahead

The team is eager to continue innovating. As the market evolves, Phillips Corporation plans to evolve right along with it, partnering with the latest technology to meet customers’ most pressing needs. Since the hybrid division’s current solutions “stem from a request from a customer to build [them] a machine,” the team is already experienced with this responsive approach. “We’re always listening to our customers and understanding what needs they have of the system, and we’ll change and adapt and meet those needs,” says Kristaponis.

The company also plans to continue focusing on the education sector. “We’re working with research [efforts] in universities to create curriculum, to train individuals. And that’s what we need to do as a company: train more people in how to run these machines effectively, because this is essentially a niche product right now.”

With the hybrid division leading the charge, these solutions are not likely to stay niche for long. “We believe that it’s going to be a mainstream manufacturing process,” Kristaponis says. “It might not be in 2025, it might not be in 2030, but we do believe that it’s coming and we need to do a better job in getting these systems out and training customers to make real parts on these systems.”

As these systems increase in popularity, Phillips Corporation will be supporting customers every step of the way, leading the market into the next era of additive manufacturing.