Approaching 30 years in business, Texas-based SVTronics, Inc. is one of America’s most respected advanced technology manufacturers. From its state-of-the-art facility in Plano, Texas—one of the key cities in the Dallas-Fort Worth Metroplex—SVTronics is renowned for high-quality electronics manufacturing and services such as electrical testing, inspection capabilities, compliance testing, and other engineering services.

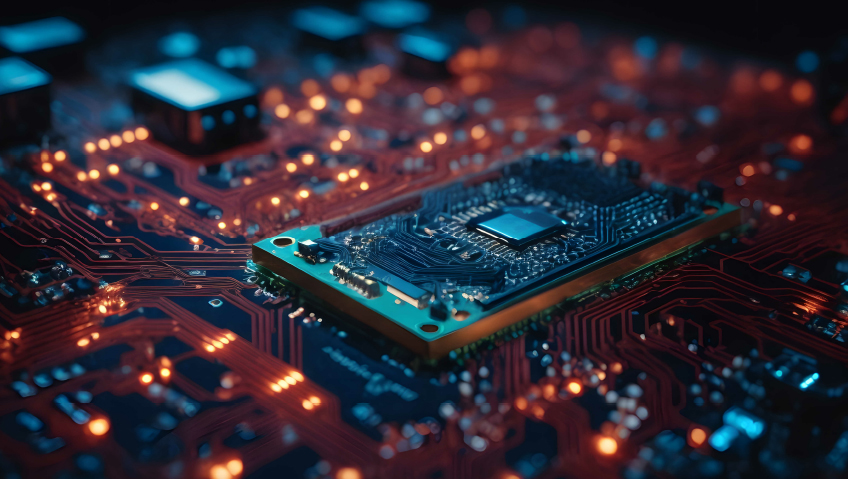

A core provider for original equipment manufacturers (OEMs) and original design manufacturers (ODMs), SVTronics continues to prove itself to be a strong and dependable partner, recognized for printed circuit board (PCB) manufacturing and assembly capabilities. Trusted by industry partners, the company serves clients in many sectors, including computing, industrial, energy, transportation, and communications. Due to the nature of its business, SVTronics maintains the highest level of client confidentiality.

The military remains one of SVTronics’ largest markets and shows little sign of slowing down. “Any country that is an ally of the United States has to buy the surplus material, like tanks, helicopters, and fighter jets,” per Chris Dickey, Vice President, Sales and Marketing. “All the support still has to be done here in the States, and we do support on all products then ship them to countries that are allies for the installation to be done.”

One-stop solutions

One of SVTronics’ greatest advantages is the company’s ability to work with clients from manufacturing inception through to completion. Growing to a team of about 150 staff including electrical engineers, radio-frequency (RF) engineers, mechanical engineers, and process engineers for manufacturing, SVTronics handles design innovation, engineering/prototyping, production line, delivery/tracking, and distribution/assistance.

To ensure the needs of all customers are met, SVTronics helps its customers source and assemble PCBs for their projects “in order to offer a seamless production process and ensure all parts meet our quality standards.” SVTronics is organized into four business groups handling electronics contract manufacturing, military/aerospace/government, cable and wire harness, and engineering services. Along with diversifying the company, this enables the team to focus on specific goals for each market while still being flexible to adapt to any changes in the market.

Some of the company’s many services include automated SMT assembly line, 3D automated optical inspection, and advanced test capabilities, to name a few. For military, aerospace, and government clients, SVTronics’ manufacturing services are strengthened through an efficient material procurement team. This helps ensure on-time delivery and a watchful eye over component costs.

The company’s quality management system serves to ensure all products undergo strict quality checks and testing before delivery, including tactical rugged computing, display technologies, systems design and integration (MIL, DO160e, TEMPEST), and more. In addition, the company is CMMC Level 3 Certified.

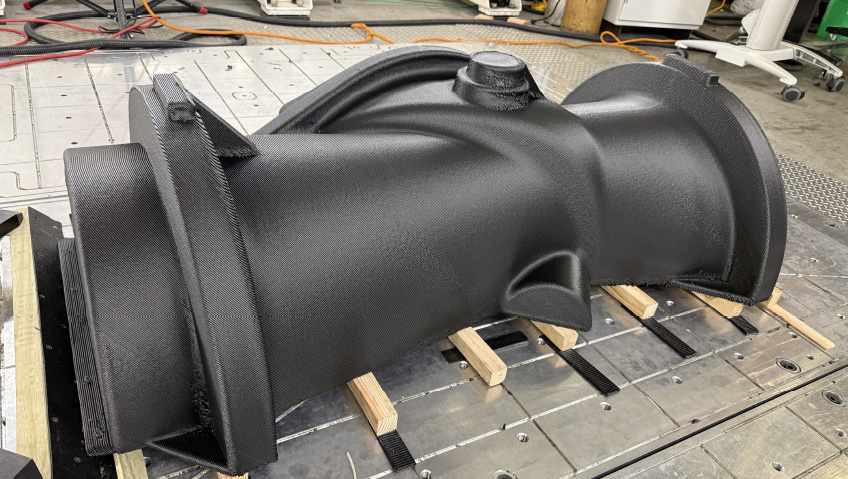

On the engineering services side, the company’s strength in helping customers with mechanical and engineering work is unrivaled. This includes SVTronics engineers working independently or as an extension of client engineering teams, taking ideas from the drawing table or an electronic design to development and production. In addition to industrial design services, the company can also print 3D parts for prototyping.

For decades, Texas has been a significant corridor for electronics and electronics manufacturing. When SVTronics was founded in May 1996, the state was home to major companies including Fujitsu, Ericsson, Motorola, and others, along with Tier 1 businesses. Prior to starting the business, SVTronics’ founders were involved in raw PCB fabrication. They soon became involved with electronics manufacturing and the assembly of printed circuit boards. The timing and market conditions were optimal.

“There weren’t any companies focusing on quick-turn prototypes,” explains Dickey. “As companies were doing new developments, they needed somebody to go to who could support their quick-turn prototypes. That’s the niche we were in at the time. Over the years, instead of us just doing prototyping, it grew into full-service electronic contract manufacturing.”

On the front end, this soon saw SVTronics adding services such as schematic capture, PCB layout, and embedded systems. On the back end, the business started adding secondary processes including in-circuit testing, functional testing, and HIPOT (high potential [high voltage] testing), also known as Dielectric Withstand Testing, an important, non-destructive test to determine electrical insulation adequacy. From there, the company evolved into electromechanical assembly, system integration, box build and full testing of box build assemblies, burn-in testing, compliance testing, and thermal testing. “So now, we are at the point where it’s a one-stop shop, and we can do everything in-house.”

Expanding operations

Continuing to grow, SVTronics recently decided to expand its electrical equipment and component manufacturing services into India. Everything is going according to plan; all equipment has been delivered to the India location and staff have been sent out to get everything installed and up and running. The goal, says Dickey, is to have everything in operation by November. With the support of existing customers in India, the facility’s operations will be similar to those in Plano.

Some of SVTronics’ certifications and memberships include ITAR (International Traffic and Arms Regulation), SMTA (Surface Mount Technology Association), ISO 9001:2015 and AS9100D, IATF (International Automotive Task Force), and MBE (Minority Business Enterprise). The SMTA hosts several conferences around the world featuring exhibits and speakers, which SVTronics often attends to spread the word about the company and its products and services.

Dickey and the entire SVTronics team look forward to the coming years, enjoying continued business from existing customers along with welcoming new clients. Proud of its reputation in the industry, SVTronics is also well-respected by its employees, reflected in its very low turnover rate. “The majority of our workforce have been here for 15-plus years,” says Dickey, and the company continues welcoming new workers with engineering backgrounds.

What does the future hold for SVTronics? The CHIPS and Science Act was signed into law by President Biden in August 2022, and as a result, billions of dollars are being allocated to boost the research and manufacturing of semiconductors in the United States. The Act, says Dickey, will benefit SVTronics and its many clients.

“With the CHIPS Act that has been put into place, there are a number of semiconductor companies jumping on the bandwagon, and we have engaged with them,” he says. This includes many of the major semiconductor companies, who are bringing their business back to the United States. Along with creating avenues of growth potential, major manufacturers are investing billions of dollars into creating massive semiconductor facilities in the U.S. And although production is still years away, it all looks promising for the future of SVTronics and the broader electronics manufacturing sector.