Instead of viewing COVID-19 as a threat, Mark Zimny, P.Eng., saw it as an opportunity to strengthen his company and deepen empathy in and for his dedicated employees.

As President and CEO at Promation—a leading integrator and automation, robotic systems, and tooling manufacturer—Zimny took the time to re-evaluate the company’s operations and approach to staff and clients alike.

A work in progress, Promation today is stronger and more successful than ever.

“We recognized some weaknesses in the company during the pandemic, fleshed things out, and reorganized,” Zimny says of the Oakville, Ontario-based business that he founded in his basement in 1995. “We made a clear split between business development and operations in terms of the work division, increased accountability in operations, and really expanded business development in the company.”

For Zimny, the pandemic was a call to action, one he still feels strongly about. Promation stepped up to take an active role, manufacturing face shields and ventilators and supplying other solutions to fight the virus.

Staff members began working at home, and today the company maintains a 50 percent hybrid model, something Zimny believes in. Recognizing the dedication of this staff of about 100, he gave everyone on the shop floor a raise. And while Promation is still measuring the results of its policy changes, the company continues improving its human resources policies, benefitting the business and customers alike.

A one-stop shop providing state-of-the-art robotic and automation solutions, Promation is active in the automotive, nuclear, industrial, aerospace and defense, life sciences, and food and beverage sectors. By providing clients with a broad range of solutions and services founded on decades of combined experience, Promation helps customers increase production, lower operating costs, boost quality, and improve employee safety.

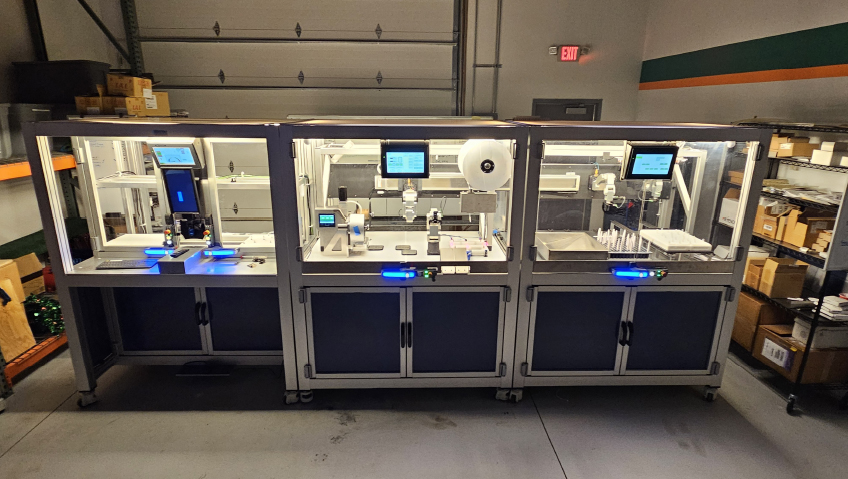

Providing tremendous value, Promation’s capabilities encompass in-house manufacturing and fabrication, 3D printing, robotics, functional testing, assembly systems, pick-and-place, automated storage and retrieval systems, and control system integration. Yet, as successful as the company is, Promation believes it can always improve.

“If you follow the Harvard Business Review monthly, you’ll find that Promation applies many if not all modern ideas about how to approach human resources in business,” Zimny says. “It’s not always easy to implement or understand, but if you have an open mind and do the required reading, and you get feedback from your employees and analyze the market, you can make adjustments and policies in response to the market. That’s my message to everybody. If you don’t do that, someone will replace you. That’s how strongly I feel about it,” he emphasizes.

“You can do all these different projects when you have a mature and innovative workforce, so they can supply their expertise and ingenuity to the projects in a consistent manner,” says Zimny. Recognizing the pandemic-related concerns of staff, such as rising inflation, the company introduced a set of new human resources policies to remain abreast of current markets and trends. Before COVID, Promation built up the capabilities of its human resources department; during the pandemic, Zimny and his team observed, adjusted, learned, and implemented changes.

Today, the company is finalizing its policies, which include increased benefits to employees overall and a generous vacation package. With a clear hybrid policy, Promation supports staff members working from home. Changing its management structure as a result of the pandemic, the company also empowered mid-level management so they could engage more and make better decisions on their own for the good of the business.

For Zimny, one of the biggest post-pandemic revelations was how to engage with employees on a different level and with greater empathy. Staff and clients alike went through uncertainty and tough times during COVID, which saw a greater need for empathy, recognizing their issues, and dealing with them in a positive way.

“Empathy for us means looking more carefully at employees,” he says. “Listen, talk, and don’t dismiss them.” This openness, combined with upgraded business strategies, increased benefits, and professional training, is seeing staff members complete work more efficiently and with less supervision, and is also helping retain clients.

“Employees are responding with superb performance,” Zimny says proudly. “Not only do we innovate for customers, but we innovate in our organization, and constantly learn how to improve Promation.” Thriving on a diversity of perspectives, the team is actively looking at ways to bring more women into the company and into engineering manufacturing more broadly.

While COVID indeed proved disastrous for some companies, it was a motivator for Promation. Active in many market segments, Promation has seen significant growth in nuclear, electric vehicles (EVs), and aerospace, to name a few.

“We delivered the first nuclear decommissioning equipment in Canada, and that’s a huge achievement,” says Zimny of the company’s work with Canadian Nuclear Laboratories (CNL) at Chalk River, Manitoba. “No one else is supplying decommissioning equipment in Canada on that scale. It’s a long-term project, and we are wrapping it up,” he shares.

“Promation has a reputation in the nuclear industry. We competed against other large companies in Canada, and we delivered the best solutions to CNL, and the best business package.”

The electric vehicle market is also a growth area for the company. This includes supplying robotic manufacturing systems for manufacturing batteries for major suppliers, along with providing robotic systems for EV motors.

Promation also expects to play a role in other projects in the works, including Volkswagen’s new battery manufacturing plant in St. Thomas, Ontario, and the upcoming multi-billion-dollar Stellantis EV battery facility in the automotive manufacturing hub of Windsor, Ontario. “The electric vehicle market is a substantial part of our work going to the shop floor right now,” says Zimny, and the company is now supplying a major system to Tesla in the United States.

While he says that Canada is hesitating a bit on EVs, the sector is thriving in the U.S., and Promation is planning an expansion. “The market is pulling us in, so we have to be closer to our corporate customers in the U.S. for the electric vehicle market.”

Innovating during the pandemic also saw Promation broaden its aerospace base. Although Zimny can’t get into specifics because of confidentiality, he says Promation has created a unique, state-of-the-art robotic manufacturing system making engines lighter, and is the sole automation supplier of this critical component.

Zimny is such a believer in the product and so committed to its success that he, as the CEO, personally got involved in direct research and development. “We want to succeed, and it’s not easy,” he says. “If I hear ‘innovation is easy,’ then it’s not innovation,” he adds. “Any meaningful innovation brings tons of work in R&D. Innovation always supplies it and guarantees solutions. That’s our position on innovation. We embrace innovation—that is unquestionable—and we get results.”

Indeed, the road toward product development was far from smooth, with pandemic-related delays in the supply chain of components, electronics in particular. The project has been challenging technologically as it requires specialty sensors, unique solutions, and the ability to operate at high temperatures and high cycles.

During the pandemic, Promation took on other challenging, innovative products for other markets. For well-known valve manufacturer Dahl, the company developed a unique, fully automated, high-speed robotic assembly system that also tests the valves.

“It’s multiple robots doing very complicated assembly systems,” Zimny explains. “The achievement is that we managed multiple part numbers and multiple models—not just one valve, but hundreds. So it’s a flexible robotic assembly system for a multitude of valve sizes and configurations; that’s an achievement in itself. Again, this product was conceived during the pandemic.”

Although the company’s work in nuclear, electric vehicles, aerospace, and rapid robotic assembly and testing is strikingly diverse, one thing is for certain: Promation knows innovation. Applying skilful engineering and a systematic approach to innovation, the company continues passing on benefits to its customers and intends to keep creating success stories in the decades to come.