Zierick Manufacturing Corporation (ZMC) is a third-generation, family-owned manufacturing company with over a century of expertise in electronics and semiconductors. Zierick began life as a small company in southern Manhattan off Canal Street, an industrial area close to the famous Wall Street, and first worked as a parts fabricator for early radio sets. Then known as F.R. Zierick Machine Works, its early specialty was in cat’s whisker receivers, so named because of the thin and fine wire it was made of.

As the technology became more practical, founder Fred Zierick and his family created the first set of mounting tangs for those receivers in 1919, enabling them to check AM radio broadcasting signals. The family pitched in to get the business off the ground, with Fred’s mother creating the first Zierick catalog.

Over the ensuing century, the company only continued to grow thanks to the efforts of the Ziericks and their capable workforce. Today, the company proudly conducts all its manufacturing in Mount Kisco, New York, staying close to its long-time home and with the Zierick family still in charge as ever.

As Vice President of Sales and Marketing Patrick O’Callaghan points out, many products with which ZMC’s own offerings interact every day involve electricity and electronics in some way, whether it’s LED Lighting, Motor Controls, or practically any other type of modern necessity or convenience. O’Callaghan says that, inside any kind of product with which something from ZMC is associated, there is usually a connection made through printed circuit boards or wires so that signals or current can move across these wires—and of course, those connections need to be supplied with power to work at all.

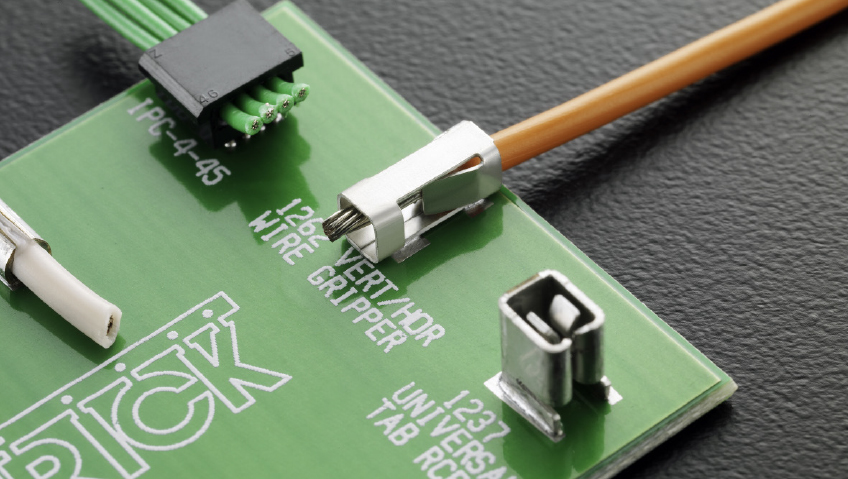

ZMC’s suite of offerings include wire-to-board, board-to-board, and wire-to-wire connectors and are found in products ranging from air conditioning systems and industrial electronics to everyday objects like cars, e-bikes, thermostats, and more. The company specializes in surface-mount technology and though-hole products that work in concert with circuit boards.

“All those devices and assemblies need the types of parts that [ZMC] designs and manufactures,” says O’Callaghan, and adapting to new demands of the market has kept the company in business for over a century and counting.

Now reflecting on another full year in 2023, the company spent its time launching new products, especially some that are particularly useful to higher temperature and higher performance applications. For example, electric cars often require high-performance connectors that can take on more electric current in a similar footprint, which ZMC’s new product offering is looking to address.

The company is also re-launching a unique four-position fine wire connector following investment in production improvements. The fine wire connector is part of a product family—in which one variant terminates a coaxial wire in a single connector instead of two separate connectors—which won the Tech Award at the World of Technology & Science fair in the Netherlands.

O’Callaghan says that the company has a unique perspective on its industry, given the types of markets it supplies to. As the semiconductor market adapts to manufacturing in each geo-region and reacts to increased demand for AI chips, there remain chip shortages in some manufacturing builds that place pressure on the electronics industry as a whole. Semiconductors are a backbone of so many products in today’s market and the industry itself is often a marker for what trends will continue over time.

In the last 12 months, due to supply chain issues and increased ordering toward the back end of COVID shutdowns, book to bill ratios have been lower than usual as the overall market adjusted; however, O’Callaghan says that the company is working on several product types across different areas, with clients moving a bit more slowly now.

The effects of this massive buying spree are only becoming clear now. Today, many of the company’s clients have an excess of raw materials and inventory with pockets of supply chain issues, meaning that bill of materials can go unassembled at times due to missing part numbers.

O’Callaghan explains that the current landscape for electronics and semiconductors is a challenging one for these reasons, but also and especially due to other supply chain issues in the wake of both the COVID-19 pandemic and the ongoing conflict in Ukraine. The situation around COVID-19 in 2020 onward created a specific set of market conditions that have led to effects of spike and inflation in the market, with a lack of materials being a noted issue for the company in the 2021 to 2022 period. This has occurred while demand for ZMC’s products has only increased, which is proving tricky for the company. Yet, there is also a sense of optimism that it can withhold against any pressure or uncertainty, especially given its considerable track record and history.

As a smaller-sized and family-owned company, ZMC aims to continue manufacturing and supporting local business whenever possible, procuring raw materials from similarly sized North American suppliers if it can. “We like to think that we support customers in North America and globally using our U.S. manufacturing base as a platform to do so,” O’Callaghan says. As 2024 is well underway, the company will be looking to launch specific parts this year to both respond to the current market conditions and innovate with new products.

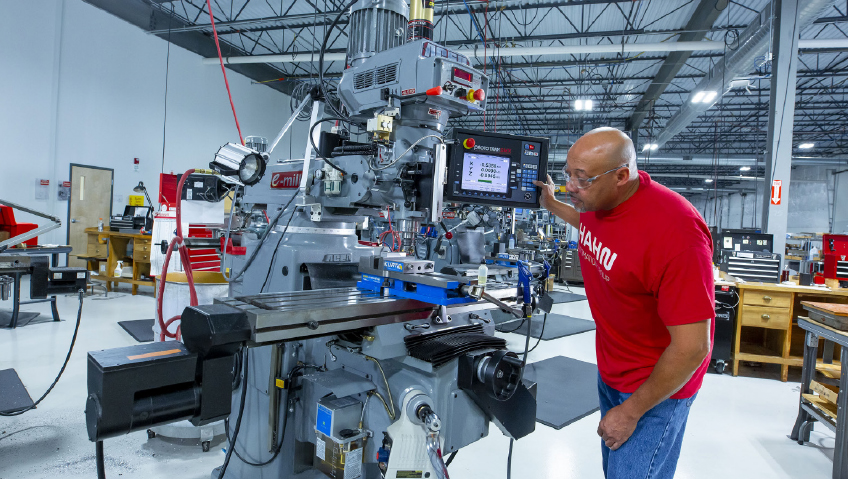

Although business going into the new year has begun at a slower-than-normal pace, ZMC wants to keep its people working, as its workforce has always been one of the company’s key assets. To that end, 2024 will be a good opportunity for the business to upskill its people where possible and to take on projects it usually is not able to during busier times. Even in slower conditions, O’Callaghan says that the company will continue to build inventory that it aims to sell later in the year and invest in its workers, and it will hardly be staying quiet even if the industry itself is.

ZMC will be celebrating its 105th anniversary this year, a remarkable achievement for any business. O’Callaghan says that this has always been a relatively conservative company, resisting the urge to grow beyond its capabilities. “We’ve stuck to niche product segments with customers we know really well.” This attitude of controlled growth has always been tempered with both an interest in the people who make everyday operations possible and in the types of products it continues to build.

A small-to-medium-sized enterprise in the greater New York area can be seen as a bit unusual in today’s market, but O’Callaghan says that ZMC continues to be successful in its own way. So many of its products are shipped overseas to areas like Europe and Asia and are built into products that are well-known and boast superior brand recognition across diverse buyer segments. Although its market niche is a bit more behind-the-scenes than others, everyone in the company is proud to supply the parts, wiring, and more that make some of the most iconic global products of today’s marketplace possible.