In 1898, Charles Grotnes (pronounced ‘Grote-ness’) founded an eponymous machine works in Chicago to provide services and products for a very specific industry. He “started a business to produce metal rings which held the staves of a barrel together,” Vice President, Jim Zielinski tells us.

Being an inventive type, Grotnes then developed a machine, dubbed The Expander, to stretch and shape metal rings to the desired size. This machine greatly sped up the process of preparing metal rings to bind barrels. He also conducted research and development in rotary roll-forming and shrinking technologies.

125 years after the company was founded, it continues to flourish from its headquarters in Niles, Michigan. Metalworking remains central to its mission, and this manufacturer of customized and integrated metal forming cells and equipment has upheld the pioneering spirit of its founder.

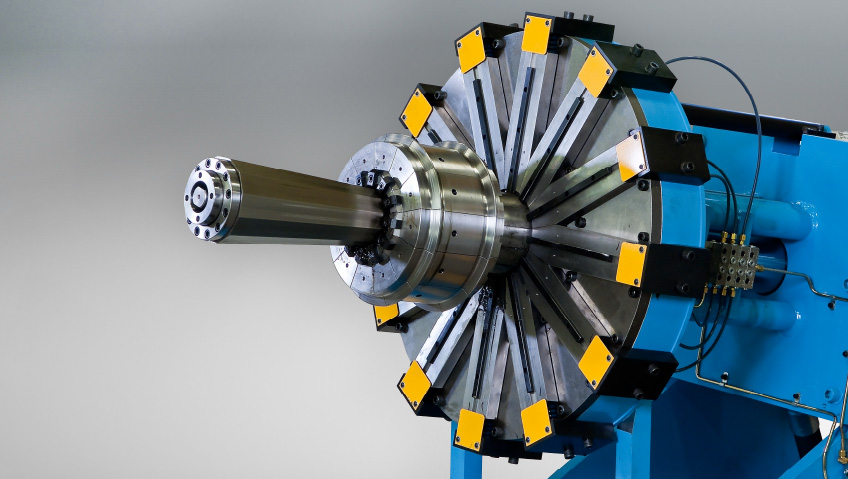

Grotnes excels at its four core technologies: shrinking, spinning, expanding, and rotary roll-forming, and all of its projects must contain at least one of these processes. For example, Emission canning refers to the “automatic or manual assembly process to wrap a catalytic converter substrate in a mat and insert the assembly into a shell,” explains the company’s website. This process “uses one of our core technologies, which is called shrinking,” notes Zielinski.

In a shrinking procedure, parts are reduced and shaped for use in jet engines, exhaust components, motor frames, and conveyor pulleys. The opposite occurs in an expanding process, through which the company shapes metal parts for fan housings, metal containers, and pipe couplings. Rotary roll-forming (a technique involving the bending of metal strips) and spin-forming (a metalworking process centered on mechanical rotation) are other in-house specialties. While the process is not new, Grotnes was a leader when it came to the spin-forming of catalytic converters.

Closing tools “are kind of a niche market for us,” shares Zielinski. The tools are used “for closing the tabs on five-gallon pails. If you’ve ever seen a five-gallon paint can, they have metal tabs all the way around.” Grotnes has held a patent on a tab-fastening closing tool for decades, and closing tool products remain “a small part of our production, but still an important one.”

In addition to designing and manufacturing custom systems, the company will rebuild and retrofit equipment upon client request and offers a broad inventory of spare parts. Prototyping and production services are also available.

Grotnes has ISO 9001:2015 certification and is justifiably proud of its reputation for high-quality craftsmanship. Maintaining ISO certification requires extensive planning, documentation, testing, and monitoring. The firm performs internal audits and has a set of stringent technical benchmarks that must be reached before work can proceed to the next stage.

Rigid packaging, forging, appliances, aerospace, power distribution, oil and gas, general industry, and automotive are the company’s main markets. Grotnes has customers in nearly 40 countries around the world, although most of its business is conducted in North America.

The sector that brings in the most revenue “varies from year to year, but probably the big three are automotive, aerospace, and rigid packaging—rigid packaging being containers for storage and transport. 55-gallon steel drums are a big part of that; we make the machines that make those,” says Zielinski.

In addition to its Michigan headquarters, Grotnes maintains sales and service branches in Atlanta, Georgia and Monterrey, Mexico. While the company doesn’t have plans to open new brick-and-mortar locations any time soon, it is eager to “develop strategic partnerships with other companies in geographic areas where we want to expand our footprint,” Zielinski says. These partnerships could involve service, sales, or manufacturing. Grotnes has already established relationships with companies in Poland and Italy and is “looking at doing the same in other strategic areas,” he continues.

The company runs a facility called Formitt Metal Labs which focuses on spin-forming fabrication to create hollow tubes assemblies. Formitt also offers production and development services for the assembly of exhaust components in vehicles and boats.

Grotnes maintains an internal machine shop as well, fitted out with metalworking tools and Industry 4.0 elements. The company established this internal machine shop “to be able to control a little bit of our own destiny because of supply chain interruptions, quality issues, and escalating costs. So we’ve made that investment to basically concentrate on critical components we could not lose control of by having delays or quality issues,” explains Zielinski.

“Internally, in our machine shop where we fabricate parts that are used to build our machines, we are connected,” he adds. Machine-to-computer connectivity—an essential component of Industry 4.0—enables the tracking of performance data and other metrics which can be analyzed to find efficiencies and improve production.

When clients face overwhelming workloads, Grotnes can step in and provide production assistance. If a customer “had a project that was going to interrupt their existing production but they did not want to turn that project down, they would subcontract us to do the manufacturing for them,” Zielinski says. On other occasions, clients might hire Grotnes to handle initial production and then purchase manufacturing equipment from the firm to finish the project themselves.

The company’s impressive longevity and success exists for a reason. “Our products are so varied and cross so many industries. If one market is down, another market may be up,” says Zielinski.

“Having technology that has remained relevant is also key,” adds President and Chief Executive Officer, Mike Walker.

The company follows the same mechanical principles that inspired Charles Grotnes when it “makes a machine that fabricates parts that are used on rockets or jet engines and a variety of other applications,” states Zielinski.

“The expanding technology that we utilize today has progressed from expanding rings that did not require any controlled tolerances, to something that holds very high and tight tolerances,” notes Walker.

When COVID struck in March 2020, Grotnes implemented health and safety guidelines from the Centers for Disease Control and Prevention and had people work at home when possible. “We still had to get creative. We had projects that needed to be tested and run off and shipped,” recalls Zielinski.

Once a project is completed, the company traditionally performs factory acceptance testing (FAT) at its facilities. If the project passes, it is shipped to the customer’s workplace and then assessed again in a process called site acceptance testing (SAT).

Due to COVID, however, customers could not travel to the plant to witness FAT for themselves, and company staff could not travel to the clients to perform SAT. “We implemented a solution where we used GoPro cameras to walk [clients] through the equipment, to show them the parts being formed, then show them parts being inspected and measured. They were able to remotely accept the shipment, so we could send it off,” he explains.

This clever tweak aptly demonstrated flexibility and creativity—two other factors that have led to the company’s success over the decades.

Grotnes currently has 43 employees in total, up from roughly 40 a year ago at this time. The company wants potential hires to show passion and an appreciation for quality and sustainability, with sustainability centering on Grotnes’ determination to minimize scrap and maximize efficiency. Technical skills in new hires are also highly valued, given the precise nature of the work.

For all this, recruiting remains the company’s biggest challenge, Zielinski shares. To ameliorate this situation, the company has established apprenticeship and internship programs to help foster the skill sets it looks for in new staff. For promotion, Grotnes attends trade shows, particularly those organized around manufacturing industries. The company also aims to enhance its social media presence to drive more people to its website, which is going to enjoy a refresher shortly.

“Digital marketing is everything now, but we still believe in having salespeople. Face-to-face is still the name of the game,” says Zielinski.

As for the future, “I think the biggest thing for us is to continue to grow the company. We need to solidify our position in the markets we serve by being recognized as the trusted leader for metal forming. To get us to where we want to go, we have to continuously improve so our customers are constantly coming back to us for repeat orders,” says Walker.

In addition to its existing offerings, Grotnes is looking at introducing standardized wares. “We are moving toward developing a line of products that are more configured to order, pre-engineered with some structure and common modular elements across a family of machines. That will basically help normalize our business cycles,” says Zielinski.

“We will still have the custom nature of our business because there are always going to be those requests, but we’re developing a standardized product line for specific industries as we go forward. That’s a strategic goal,” he adds.

“We’re kicking that off now. It’s going to take a few years; five years from now, we anticipate that to be a big part of our product offerings.”

Visit www.grotnes.com to find out more.