Simplicity can be elusive, and achieving it can, at the worst of times, lead developers down endless warrens of complexity—especially on large, high-stakes projects. At Ascension Automation Solutions, achieving optimum results through minimal complexity has become a sophisticated art form worth perfecting.

Specializing in on-site fabrication, automation, and turnkey services that include 3D modelling and building collaborative robots, the company provides North American and international customers—especially in the automotive industry—with rapid, relevant, and comprehensive product innovation and data handling by cutting the clutter.

Adept at taking projects from concept to delivery, the Ascension Automation Solutions team is well-versed in studying its clients’ applications to engineer automation solutions that blend well into existing modular systems or can function as standalone units. And, with self-sufficiency as the mainstay of its operational model, every department is fully equipped to function as an independent module of a greater whole, providing the business with a level of efficiency and speed that is otherwise difficult to duplicate.

Based in Canada in Cambridge, Ontario, and the United States in Lansing, Michigan, the company’s integration goals also support outsourcing when needed—a decision that has brought considerable expansion to its operation as it pursues ever-greater possibilities. In addition to its complete fabrication outfit, Ascension Automation Solutions is a real-time data wizard. “We have a full-service software team as well. We have data collection systems [that allow us to] harvest data on their systems, live, and present them with real-time, true data feeds in their facilities,” says Andrew Morgan, founder, CEO, and Automation Manager.

The software team comprises 17 seasoned coders who bring a breadth of expertise to their positions. While some are automation specialists, others focus on analysis and development. And by turning to big names like Mitsubishi, Siemens, Allen-Bradley, and Omron to supply components like programmable logic controllers (PLCs), which are, ultimately, data-gathering industrial control systems, customers are guaranteed superb quality.

“We come at this from an industrial perspective,” explains Morgan. “We are some of the only people in the market offering software at this level. The analysis tools are an insane value-add.” Offering customers the ability to simply connect a laptop to access current information gleaned from thousands of robotic units or an entire factory’s equipment in a flash makes Ascension’s trailblazing software singular in its efficiency and relevance.

The dynamic problem solvers that call Ascension Automation Solutions home typically have considerable tenures in the industry, bringing to market fresh ideas underpinned by years of experience. The result is quality automation that provides ease of use and ownership by optimizing performance while keeping costs in check.

“The goal is not only to solve a problem; it is to solve it with the minimum complexity. Minimalist automation is a good term for it,” Morgan says. This approach translates into consciously finding ways of easing up the obvious, like converting hardwired sensor cables—with their natural propensity toward absolute chaos—into plug-and-play units for easy replacement later. “We do very well as a team tackling such challenges with our varied experience and by bringing the different teams together at the different stages,” Morgan explains.

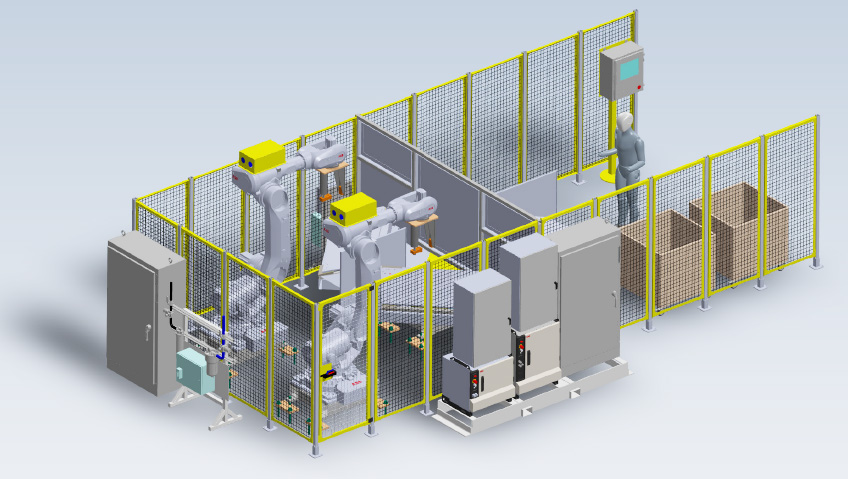

However, the company does not only serve the automotive industry. Two of its most exciting current collaborations include a project with FibraCast, a leader in the wastewater filtration technology industry, and another for Guelph Manufacturing Group. “They’ve been a great customer of ours for the last year or so. We are increasing their productivity with our system,” says Morgan of the project that has seen Ascension develop a custom modular robotic welding cell system in less than six months. The modular aspect allows for the easy addition of other components and technology, making it a long-term investment that will continue adapting to its owners’ needs.

When it comes to infrastructure, the company supplies its professionals with only the best. As a result, its top-notch machinists, electricians, and fabricators have access to a well-stocked collection of equipment, enabling them to achieve their objectives—often on enormous projects. Of course, as an automation leader, much of the company’s repetitive tasks, ranging from production to coding, are indeed automated, allowing the team to focus on what humans excel at.

“We take on these multi-million dollar projects, and we can manage them as well as a $3,000 project because the custom-built systems are set up to handle it,” Morgan says. The concept of developing excellence within each department to serve each other as independent providers also gives the company and its people tremendous power to excel through determination and creativity.

Naturally, it took incredible effort and investment to establish this well-calibrated eco-system. But the result is well worth it, as the company’s growth indicates. “Instead of outsourcing all these different [services], we have our own, vertically integrated supply chain under one roof. It makes it easy to take on any size job,” Morgan says of this year’s company-wide target to outsource minimally. The challenge gave life to Ascension’s new 1000-square-foot paint booth, complete with 14-foot ceilings.

Establishing the company in September 2013 with the mission of supplying programming services like integration, system design, and project management to large automotive companies, the original team visited customers on-site, collaborating with in-house teams. When COVID-19 arrived, Morgan committed to growing the business alongside his team of around 10. Together with childhood friends Jesse Cutting, co-owner and Service Manager, and Timothy Piper, co-owner and Operations Manager, Morgan set out to re-establish the company in a new format in 2020.

With years of combined electrical and manufacturing engineering expertise, the two new leaders stepped up to the challenge of turning Ascension Automation Solutions into a self-sufficient automation fabrication powerhouse alongside their new partner. Taking the company from an annual $500,000 to $2.6 million in revenue in its first fiscal year, the trio grew the company to around $15 million and 150 staff, achieving an incredible upward trajectory by any standards.

“It’s been pretty wild. We started with the three of us in a garage… and we have turned it into what it is now, and still looking to expand,” Morgan says of the partnership and the global economic crisis that boosted the need for automation like never before.

Fully certified to do what it does best, including holding Canadian Welding Professional (CWP) status, around nine key team members (with more to come) are certified Vision Professionals. That means holding the latest A3 certifications by A3 Vision & Imaging, supported by the Association for Advancing Automation. As a sought-after, practical certification held by comparatively few professionals globally at present, companies like General Motors have set the bar by making this qualification a prerequisite for working on its integration projects.

As somebody who describes himself as being precise by nature and holding himself and his work to the adage that says “good enough is never good enough,” Andrew Morgan sets similar standards for the team. “We have been really lucky that our whole team, to one degree or another, brings that mentality to the table,” he says proudly. “There is nobody on our team who does not have that.”

At Ascension Automation, merely fulfilling contracts is not the standard. Instead, fulfilling contracts outstandingly well is the goal. That is what keeps customers returning with ever-growing projects. To consistently achieve this also means building team spirit, and to this end, the company hosts regular events that allow staff members time to get to know one another better and cement friendships, building the synergy demanded of complex projects.

Building bonds in the community as well, the company has also donated its fair share of cutting-edge technology, including a robot, to institutions like Conestoga College, allowing students to familiarize themselves with its work and learn how to operate such complex machines. It also donates generously to charitable organizations, and pledges all proceeds of its end-of-year celebrations to charity.

Rapidly hurtling toward the end of the year, charity is not the only topic on this leader’s mind. Artificial intelligence and its change-making trends are at the top of Andrew Morgan’s list of technologies to keep an eye on. “Humans are more suited to doing complex tasks,” he says. “Basic visualizations are honestly a waste of a person’s time… to load and unload parts and look for a little scratch. People are smarter than that,” he says of collaborative robot automation becoming sharper and more affordable, making it more accessible to mainstream businesses. The trend holds great promise for the company’s continued evolution.

Following its truly sterling growth of the past three years, Ascension’s next horizon features a facility footprint of somewhere between 60,000 and 80,000 square feet—that and a line of exciting new products currently being developed.

Alongside this, the company is also setting itself up as a big brother to smaller companies needing automation and fabrication by consistently deepening its own capabilities. Morgan is clear in sharing his grasp of customer needs: “We know what you need because we work here, too.” There is only one thing as solid as this team at Ascension Automation Solutions: its commitment to giving all its customers a leading edge.