Since Manufacturing in Focus profiled the engineering firm in November 2021, LasX Industries Inc. has developed a new process controller, established a new business development team staffed by in-house experts, and honed its capabilities in precision converting and other applications…

From its headquarters in St. Paul, Minnesota, this company designs and manufactures patented high-speed, high-resolution industrial laser processing systems for the manufacturing sector. Its laser-enabled solutions can be used to cut, etch, engrave, perforate, and ablate a variety of flexible materials, from metalized films and paper to metal foils, adhesives, plastics, and textiles.

Founded in 1998, LasX serves clients around the world in markets such as packaging, automotive, aerospace, graphic arts, medical, and electronics.

The company has long prided itself on staying ahead of the technology curve. To this end, LasX will soon launch a new version of its laser process controller called Proton λ. This soon-to-be-released solution will continue to shake up the industry in high-speed, high-resolution laser processing of flexible materials.

Proton λ is “setting us up for the future. Part of the initial motivation [for introducing this product] is the semiconductor chip shortage. We’re trying to get things up to date,” says LasX Vice President of Technology Tom Weigman.

An industry-wide issue, the computer chip shortage largely stems from supply chain chaos and manufacturing shutdowns resulting from the COVID pandemic. LasX’s recent developments in laser and high-performance processing technologies also spurred the development of the Proton λ.

New lasers pulse extremely quickly and standard controllers or microcontrollers are not capable of maintaining the data processing pace required to keep up. Speedy lasers require “a faster controller and a faster motion system… otherwise you’re just piling stuff up, and you’re wasting it,” Weigman says. “That’s kind of the state of the industry right now; there are a lot of lasers just sitting there with a lot of unused potential, so we’re tapping into that,” he explains. LasX’s Proton λ, by contrast, is capable of making “nanosecond responses to stimuli, whether that’s inputs from sensors or from other things.”

In addition to ultra-fast laser processing speeds that are up to ten times faster than some competing solutions, the compact Proton λ controller offers excellent resolution and facilitates new raster applications (based on digital images, raster applications include web design and digital photography programs). Proton λ can mark and etch complicated patterns in speedy fashion and can be upgraded into all existing LasX laser systems. It represents a good fit for multiple markets, including electric vehicle manufacturing and laser marking.

While Proton λ marks a new stage in the evolution of LasX technology, the company’s mission remains the same: to “bring high-speed, high-resolution laser processing solutions to manufacturing,” says LasX Chief Executive Officer William Dinauer.

Cutting-edge as the Proton λ might be, it is par for the course for a firm that has always emphasized out-of-the-box thinking and proprietary solutions. “Tom and I, when we started the company back in 1998, we made the choice to develop the controls with our technology,” recalls Dinauer.

Two years after LasX was launched, the team introduced the LaserSharp® Processing Module (LPM), a solution the company now describes as its flagship product. Over 500 LPMs have been delivered to customers to date. The LPM is analogous to an engine, where the LPM is designed to go into any material handling system (roll-fed, sheet-fed, discrete part automation). Each LPM consists of a laser source, beam delivery, focusing optics, beam motion system, Proton process controller, and Lightguide® operating software.

LasX is not just about advanced solutions, however. The company also has a program called ClearCut® Equipment and Process Service Contract designed to enhance the client experience. Through ClearCut, customers can receive remote support, training, discounts on spare parts and labor, software upgrades, and equipment performance checks. ClearCut also connects LasX’s laser processing experts to assist clients who “need process support to adapt the laser technology to new products or materials,” Dinauer adds.

While LasX is perfectly capable of addressing customer concerns as they arise, ClearCut takes a proactive approach that aims to prevent problems from happening in the first place or create additional value that the LPM delivers to the client’s manufacturing operations.

In the same spirit, the company recently established a Global Solution Development (GSD) team to offer consolidated expertise and add another element to LasX’s customer support capabilities. The GSD team consists of roughly a dozen engineers and laser processing experts who are responsible for helping clients in various ways, including through the development of precision converting solutions.

“Precision converting is essentially an application where the customer wants to go fast and accurate. That generally encompasses applications in industrial manufacturing like medical manufacturing, electronics, automotive, aerospace. These people are processing materials that require lasers to be very precise, fast, and reliable,” says Dinauer.

Say a customer wants to run a new precision converting process but is not completely sure of how to set it up. That client can contact LasX’s GSD team, which will then work with the customer to develop a process proposal. The GSD team might recommend that the client upgrade their software or acquire a new laser. In this manner, the client’s existing laser processing system continues to maintain value, Dinauer explains, adding, “Global Solutions Development remains as a tool for customers to use after installation to support the LaserSharp Processing Module and the laser processes running the LPM.”

The GSD initiative is “a way of doing business with clients in a confidential and responsive manner. Global Solutions Development basically connects our laser experts up front with the customers; it’s getting that technical expertise, working with the customer, making sure we work through the process,” says Weigman.

While the company has always offered such services, LasX decided it was time to codify these practices and “deliver a solution that’s long-term for the customer. That means we tailor the LaserSharp Processing Module to meet [the customer’s] process and tailor the equipment that we deliver,” Dinauer says. By providing long-term solutions, the company builds long-term relationships with its customers.

While happy to assist customers of any size, the solution realization team offers specific benefits for big companies. “The recent trend by large manufacturers is cutting back on some of their internal laser development. It’s a lot of infrastructure to support internal laser development teams, and LasX can get it done much faster,” says Weigman.

In such cases, the Global Solutions Development team is “available to come in and say, ‘We can be your laser experts.’ Weigman continues by saying, ‘Yes, you’ve already worked with this laser resonator manufacturer, you already have a potential solution here, let’s make that into reality.’ We have knowledge of the laser process and we have enough manufacturing and automation knowledge to work with the end users. We provide that bridge.”

LasX continues to operate a European branch in addition to its base in St. Paul. This branch was recently relocated from Frankfurt to Chemnitz, Germany and helps support the company’s international customers in Europe and Asia. For over a decade, a LasX spin-off company called FlexPak Services has also been offering converting services and equipment solutions for the flexible packaging industry. In 2021, FlexPak launched a LasX roll-fed machine called FreshFocus™ that offers speedy laser scoring and perforating to create packaging that is both easy-to-open and breathable. Designed for perishable foods like produce and meat, breathable packages contain tiny holes to allow in oxygen to maintain freshness. FreshFocus extends the life of produce—a boon for wholesalers, grocery stores, delivery companies, and consumers alike.

The FlexPak spin-off is “going very well. FlexPak has been expanding, and has added product development and deployment to FlexPak’s mission,” says Dinauer. FlexPak just released a new degassing vent for coffee packaging—PrimeVent®—for example.

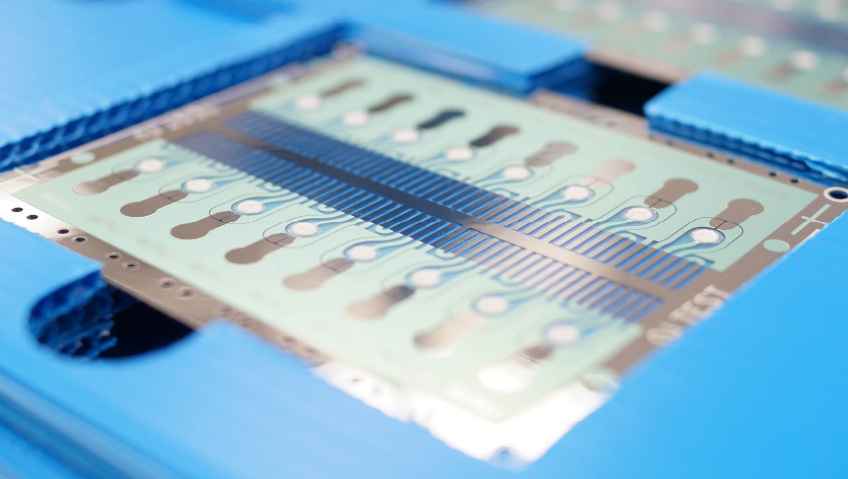

LasX also maintains an ISO 13485-certified division called MicroMed Solutions that manufactures biochips based on microfluidic technology, or the manipulation of minute quantities of fluid. Biochips are specifically designed for use in medical and biological environments, including in-vitro diagnostics, wearable drug delivery, and flow cells. MicroMed utilizes laser processing, chemistry dispensing, and other solutions to manufacture biochips. The technology used by MicroMed to laser cut and ablate microfluidic circuits was developed by members of the Global Solution Development team, says Dinauer.

Going forward, LasX is extremely excited about the upcoming Proton λ product launch, the Global Solution Development team, and the focus toward precision converting. The outlook for LasX’s future is certainly bright.

“Think of Global Solution Development as an incubator for new manufacturing processes and products related to laser material processing. LasX remains focused on maximizing customer experience in incubating new products, new solutions, and new companies,” Dinauer shares.

“Our journey with Global Solution Development is the anchor for the future of LasX. We remain committed to high-speed, high-resolution laser processing,” he says. “Our controls integration of multiple lasers, sensors, robotics, automation, and inspection will yield a lot of new manufacturing solutions designed for flexibility and highly integrated into manufacturing workflow. I know our team of Laser Experts can do it!”