The Centre for Commercialization of Regenerative Medicine (CCRM) has an international reach. Launched in 2011 as a public-private partnership, CCRM aims to take advantage of Canada’s strengths in the science of regenerative medicine and transform them into commercial opportunities. CCRM looks to accomplish this goal by creating and investing in companies, developing technologies, enabling academics and industry with advanced manufacturing, and collaborating with institutions outside of Canada to form a global network to scale innovations and support commercialization.

President and Chief Executive Officer Michael May says that the essence of regenerative medicine is treatment for human disease that represents cures for a disease as opposed to treating symptoms. Regenerative medicine aims to create durable treatments or cures through “living therapies,” which involve genetically modified cells, just one of the advanced therapies at the forefront of the sector.

CCRM was able to begin its mission in 2011, thanks to federal government funding, with additional support coming later from industry, academic institutions, and other investors, leading it to eventually becoming self-sustainable. The organization has helped financially and strategically support almost 20 companies so far, as well as launching significant companies in the space such as OmniaBio Inc. and Notch Therapeutics (a business dedicated to cellular immunotherapies, based out of Toronto and Seattle).

CCRM’s goal is to build a thriving regenerative medicine ecosystem in Canada, while establishing a global network of CCRM hubs following the Canadian model. CCRM has also further refined its focus to include building manufacturing capability to support cell and gene therapy developers in Canada and internationally, and access to capital. May says that driving company creation has always been about enhancing deal flow in the ecosystem; by attracting outside capital, CCRM can use part of that capital to reinvest back into the ecosystem and create a healthy pipeline.

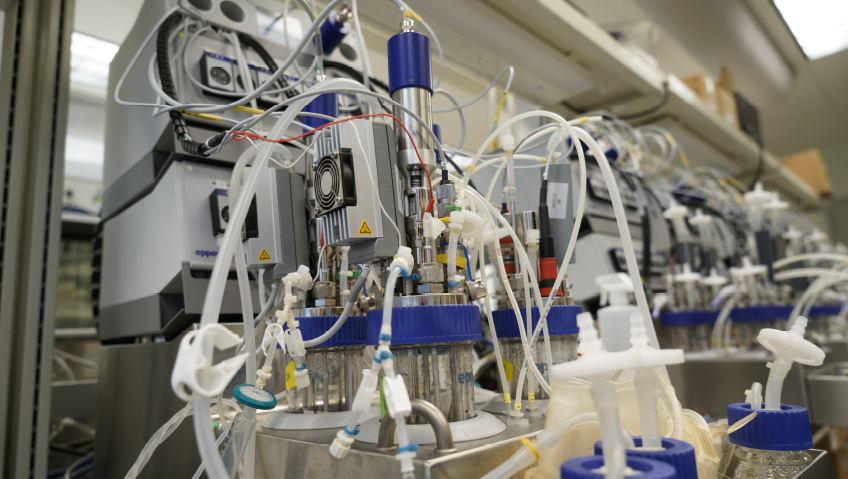

A big part of the organization’s efforts resulted in the launching of OmniaBio Inc. as a contract development and manufacturing organization (CDMO) in 2022. This new CDMO specializes in manufacturing cells and viral vectors (used in gene therapies) for customers in the North American market and elsewhere. OmniaBio grew out of CCRM’s early-stage manufacturing capability to offer commercial-stage manufacturing for cell and gene therapy companies that are ready to go to market—infrastructure that didn’t exist in Canada before OmniaBio.

During its 12 years, CCRM has built up its manufacturing capability by developing technologies and partnering with industry leaders like Cytiva and the University Health Network. This activity reached a size that attracted outsiders to the idea of a spinout of CCRM’s capabilities.

OmniaBio Chief Executive Officer Mitch Sivilotti says that CCRM helped to increase the size, expertise and capabilities of the manufacturing sector within Canada’s regenerative medicine ecosystem. This provided the foundation for companies like OmniaBio to grow. Now, building OmniaBio’s manufacturing capacity to increase the commercial supply that it can provide is the next target, which in turn will be enabled by the continued growth and maturity of the Canadian regenerative medicine sector at large.

The COVID-19 pandemic made many realize the importance of having domestic manufacturing, especially in therapeutics and vaccines. May says that the best way to prepare for future health crises like pandemics is to have a vibrant, sustainable, and growing bio-manufacturing infrastructure, talent pool, and industry. Looking beyond pandemics, these factors will also support the growing regenerative medicine field. CCRM and OmniaBio represent an enhancement of that bio-manufacturing capability.

Sivilotti says that the industry is building both capabilities and proof of the usefulness of therapies and technologies in regenerative medicine. The conversation is now turning toward market access and how to make expensive treatments, in many cases cures, available to patients, a discussion that will likely continue over the next five years.

May says that, with the added attention to manufacturing that the pandemic brought about in so many sectors, it is a process that is now understood better within the context of the industry at large. “People and skills, particularly hybrid skills, are at the heart of bio-manufacturing,” he says, which is why training operators and manufacturers in such a complex space is so key to the CCRM model.

Sivilotti says that an example of this is seen in OmniaBio’s strategic relationship with the Canadian Advanced Therapies Training Institute (CATTI), a company, driven by CCRM and Montreal-based CellCAN, that is helping create hands-on Good Manufacturing Practices (GMP) training. To accomplish this, CATTI has opened a training site at the University of Guelph that will build on the virtual training it currently offers and provide in-person training for operators working in manufacturing facilities.

May says that the biotechnology industry has seen a downturn in the last year or two, but that CCRM and OmniaBio are doing very well right now. Both companies are keeping up with the continued growth in the industry and with general investment and interest growing in it as well. “This type of research represents the exciting future of medicine.”

May says that demonstrating and adopting new technologies in the industry is ever important. Two leaders in the field are Swiss healthcare company Novartis, the first to get a gene therapy approved in the United States, and Kite Pharma (acquired by Gilead Sciences). Its CAR T-cell therapy, Yescarta, is used to combat non-Hodgkin’s lymphoma. More people are seeing real outcomes and better efficacy from modern medical treatments, delivering on the promise of cell therapy and regenerative medicine.

Growth not only continues for the industry, but even more significant growth is forecast, which CCRM will look to use to its advantage. Sivilotti says that venture capital investment in 2021 and 2022 was enormous, so the next year or so will likely be a much-needed regrouping phase for companies to focus efforts on their leading development programs.

CCRM becoming self-sustainable after 12 years was a big recent milestone, and it can look forward to working with industry and the public sector while remaining in control of its destiny. Its long-term strategy is to scale its operations and apply the country’s scientific strengths while becoming a global leader in the field.

As mentioned earlier, part of that strategy involves establishing CCRM hubs around the world to scale company creation and access to capital while strategically connecting manufacturing around the world and enabling outfits like OmniaBio to think on a global scale as well. So far, CCRM Australia and CCRM Nordic (based in Sweden) have been established, with more such hubs on the way.

Investment in the industry will be even greater than before, with plans by CCRM to launch a venture fund to help provide additional horsepower to the Canadian economy and the CCRM network. “We’re looking forward to leveraging everything we’ve done and increasing access to capital,” May shares.

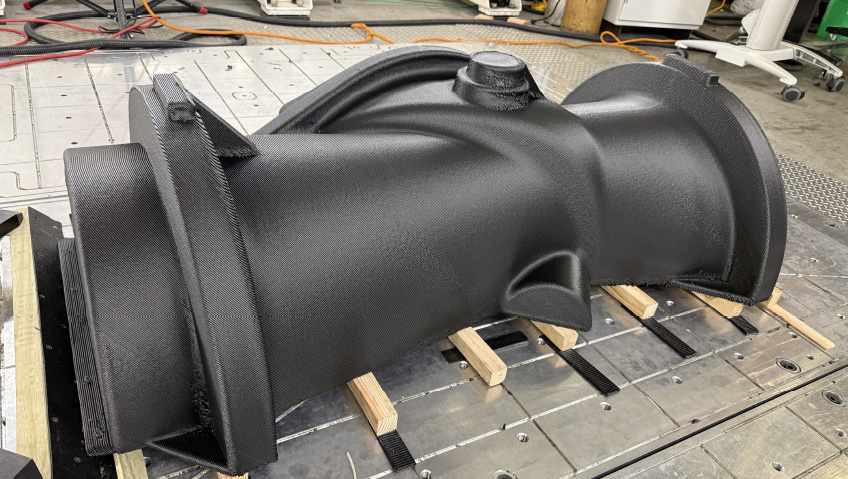

To meet its own growth goals, OmniaBio is planning to hire 1,000 personnel over the next five years to meet the needs of its industry customers. It is in the midst of construction of a new facility at the McMaster Innovation Park, which can be seen from the highway running alongside Hamilton, Ontario, just west of Toronto. The site broke ground in 2022, and the first building will be completed by the second half of 2024. Once all of the construction is complete, it will represent a 400 per cent increase in its manufacturing capacity, something that Sivilotti says is exciting for staff, customers and ultimately patients.

When it comes to the outlook of CCRM, OmniaBio, and the regenerative medicine industry, “We are cautious, but things are booming,” says May. The space holds a lot of promise and CCRM will be a part of the many burgeoning opportunities within it for the foreseeable future.